Concrete for slope protection blocks and method for preparing slope protection blocks

A technology of concrete and blocks, which is applied in the field of embankment slope protection engineering, can solve the problems of air pollution and dust generation, and achieve the effects of low price, convenient construction, and improved compressive and flexural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

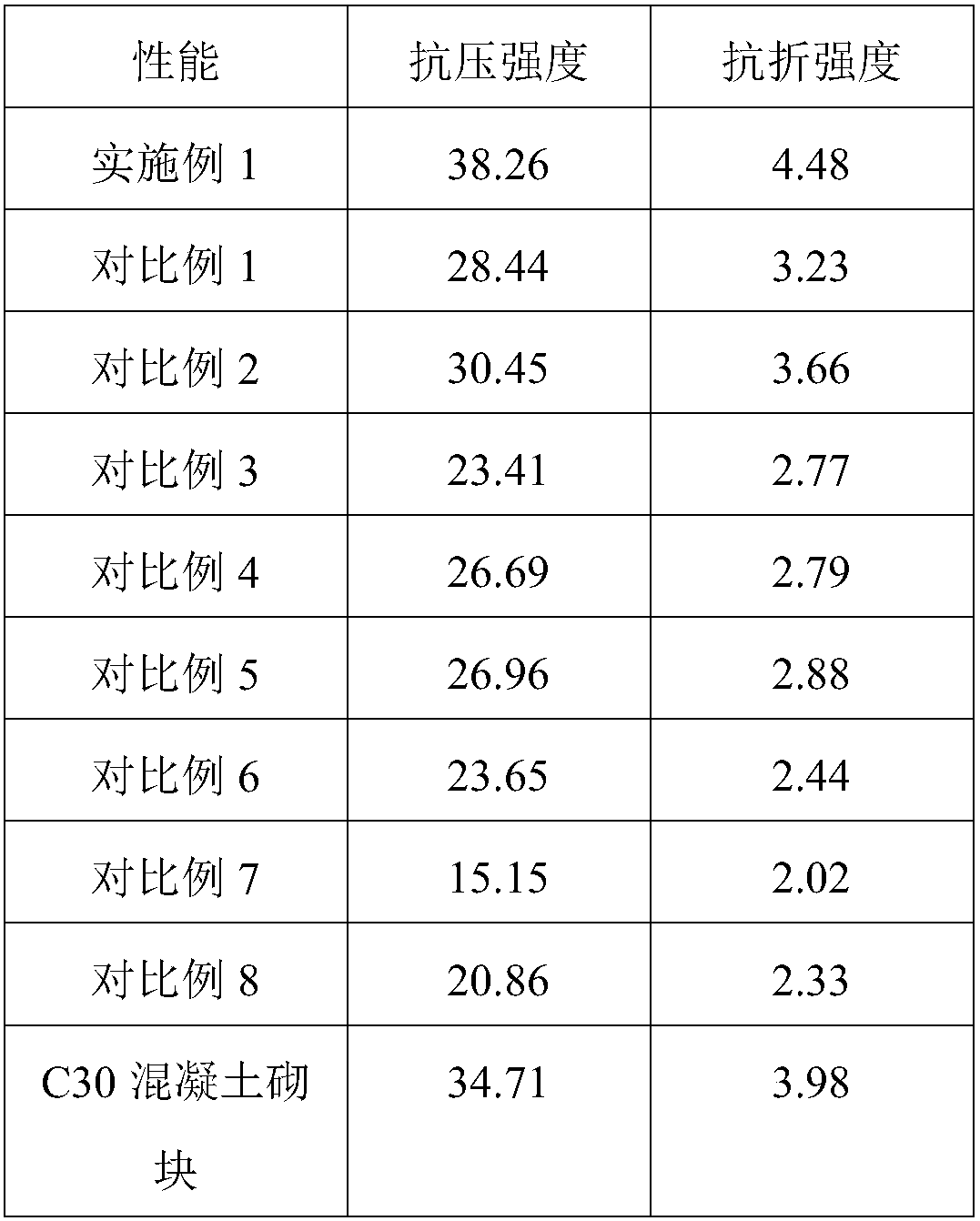

Examples

Embodiment 1

[0030] Embodiment 1 A kind of preparation method of slope protection block

[0031] The preparation method comprises the following steps:

[0032] 1) The selection of gravel should consider its toughness and strength, the content of harmful impurities, particle gradation, particle shape and surface characteristics. In this embodiment, crushed stones from a better quarry are selected, and the maximum particle size is controlled within 40mm, which meets the requirements. Natural sand requires the fine aggregate to be hard in geology, low in harmful substances, and clean. In this embodiment, medium sand is selected to meet the requirements. The steel slag selected in this embodiment is the steel slag produced by Jinan Iron and Steel Co., Ltd., which is massive steel slag, black in color, heavier than pebbles, rough in surface, more pores, below 20mm in particle size, and continuous gradation of 5-20mm. fulfil requirements. Firstly, the sieves are listed from top to bottom in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com