Annular electrostatic spinning device and electrostatic spinning method

An electrospinning, loop-like technology, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of insufficient solution utilization, unstable production process, volatile solvent, etc., to improve solution utilization. efficiency, improving spinning efficiency, and reducing solvent volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

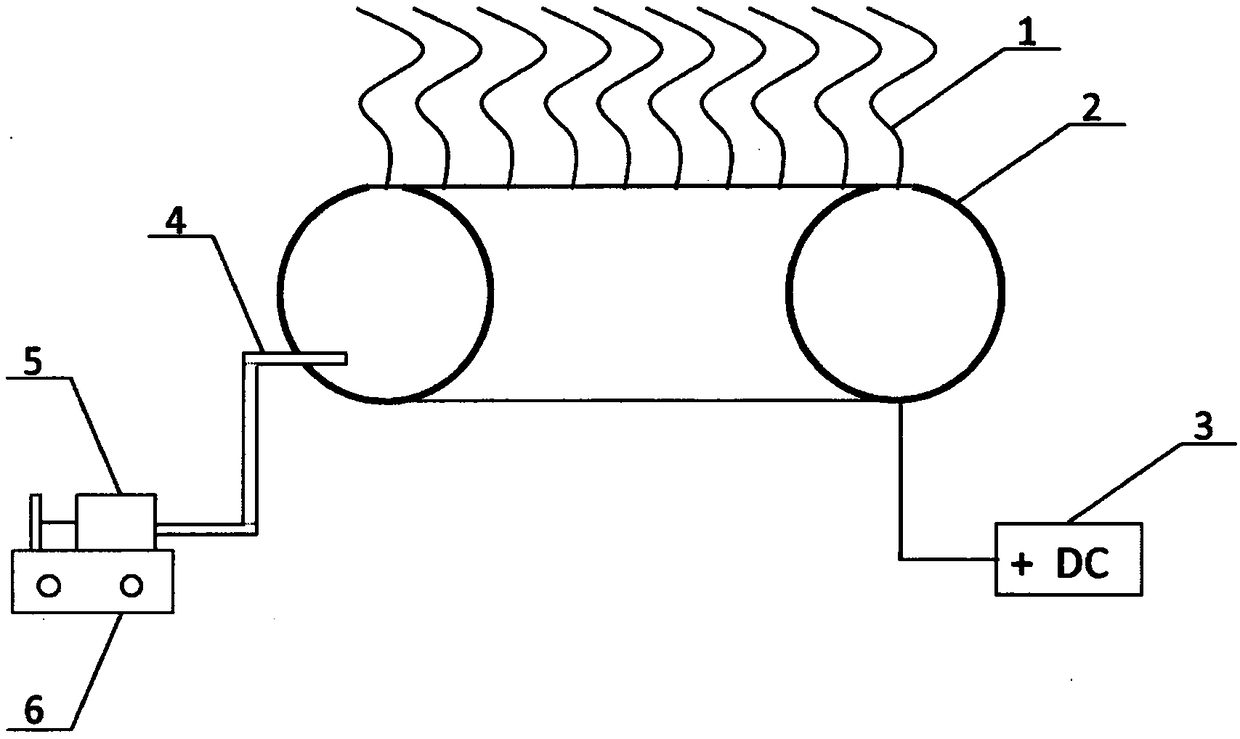

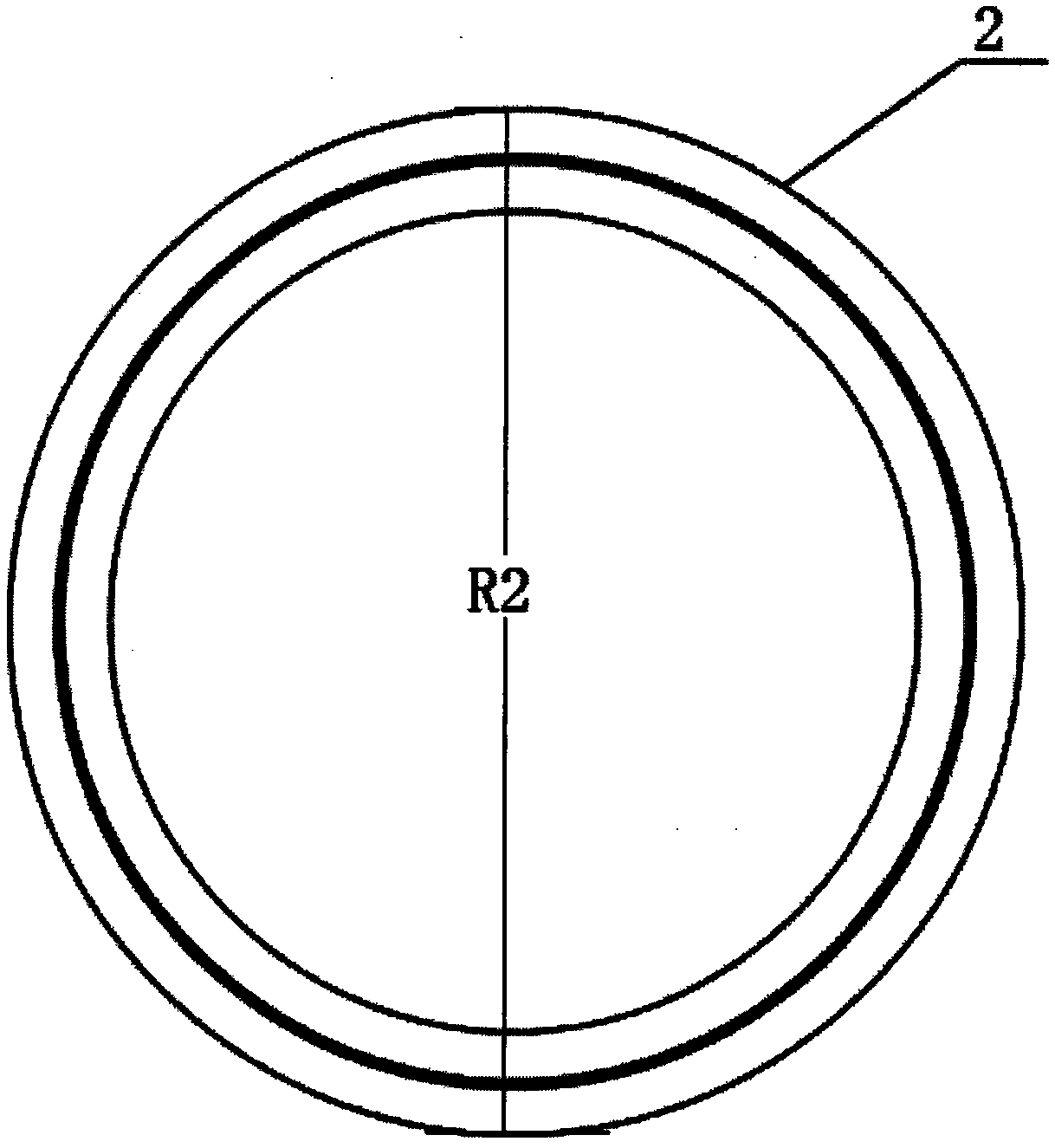

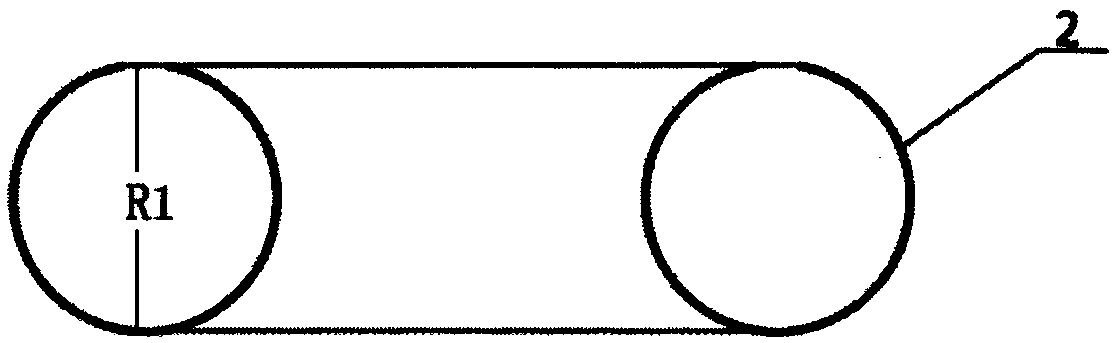

[0025] Such as figure 1 As shown, the ring-shaped electrospinning device of this embodiment includes a ring-shaped spinneret 2 and a liquid supply device connected to the ring-shaped spinneret 2 for supplying spinning solution to the ring-shaped spinneret 2. The inside of the annular spinneret 2 can accommodate the spinning solution supplied by the liquid supply device. The annular spinneret 2 is provided with a gap. The annular spinneret 2 is connected to the high-voltage positive electrode 3. When the voltage exceeds the critical value, the A plurality of electrospinning jets 1 can be generated in the gap. The liquid supply device includes a digitally controlled micro-injection pump 6 and a syringe 5. One side of the annular spinneret 1 is implanted with a hose 4, and the output end of the syringe 5 is connected to the annular spinneret 2 through the hose 4. The digital control micro-injection pump 6 is used to control the flow rate and flow rate of the spinning solution ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com