Efficient methanol high-temperature cracking furnace with automatic carbon burning function

A high-temperature cracking and methanol cracking technology, applied in furnaces, charge materials, furnace components, etc., can solve the problems affecting the product quality of spheroidizing annealing furnace, incomplete cracking, a large amount of carbon powder, etc., to reduce temperature rise, increase cracking distance, The effect of large gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

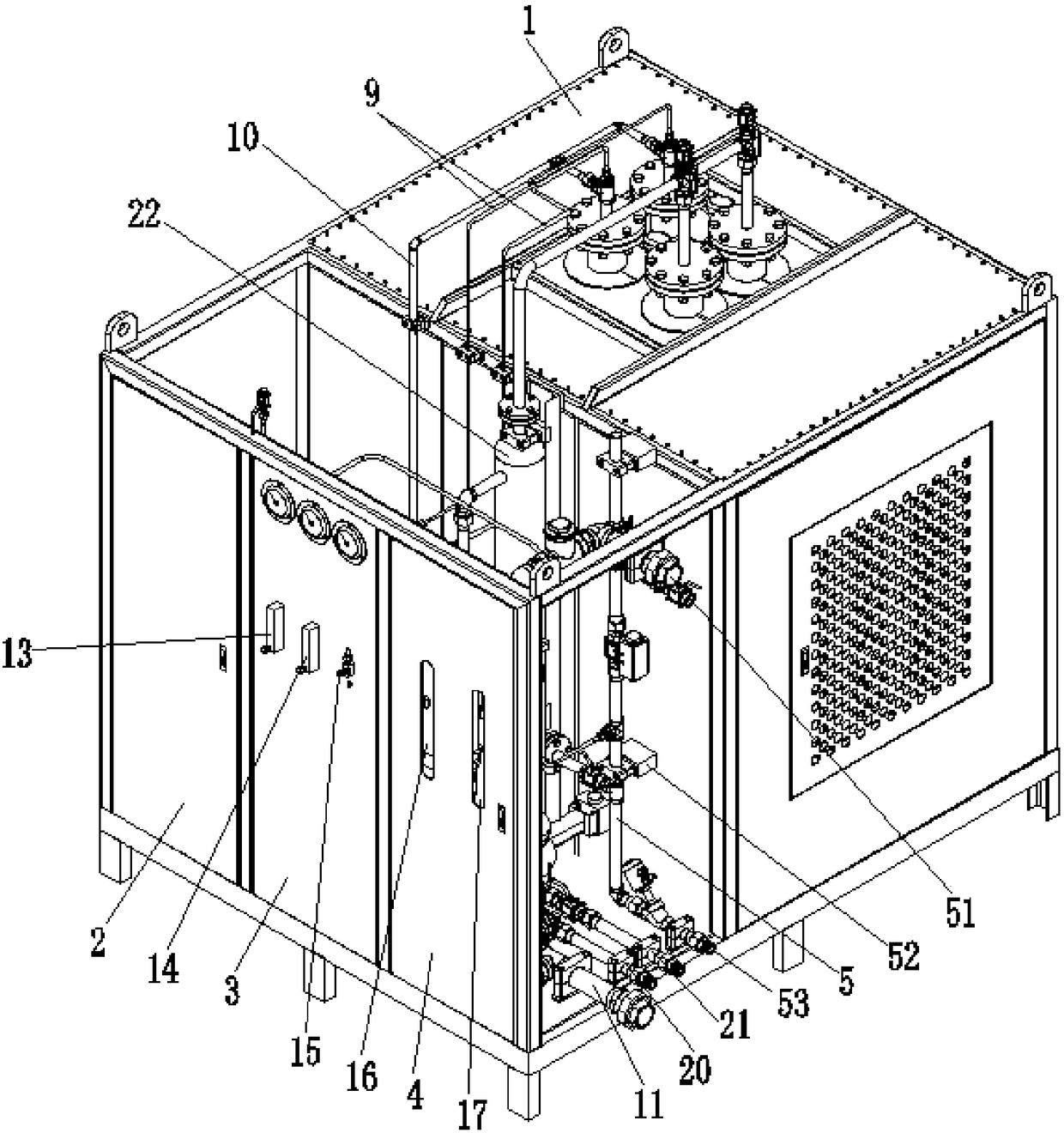

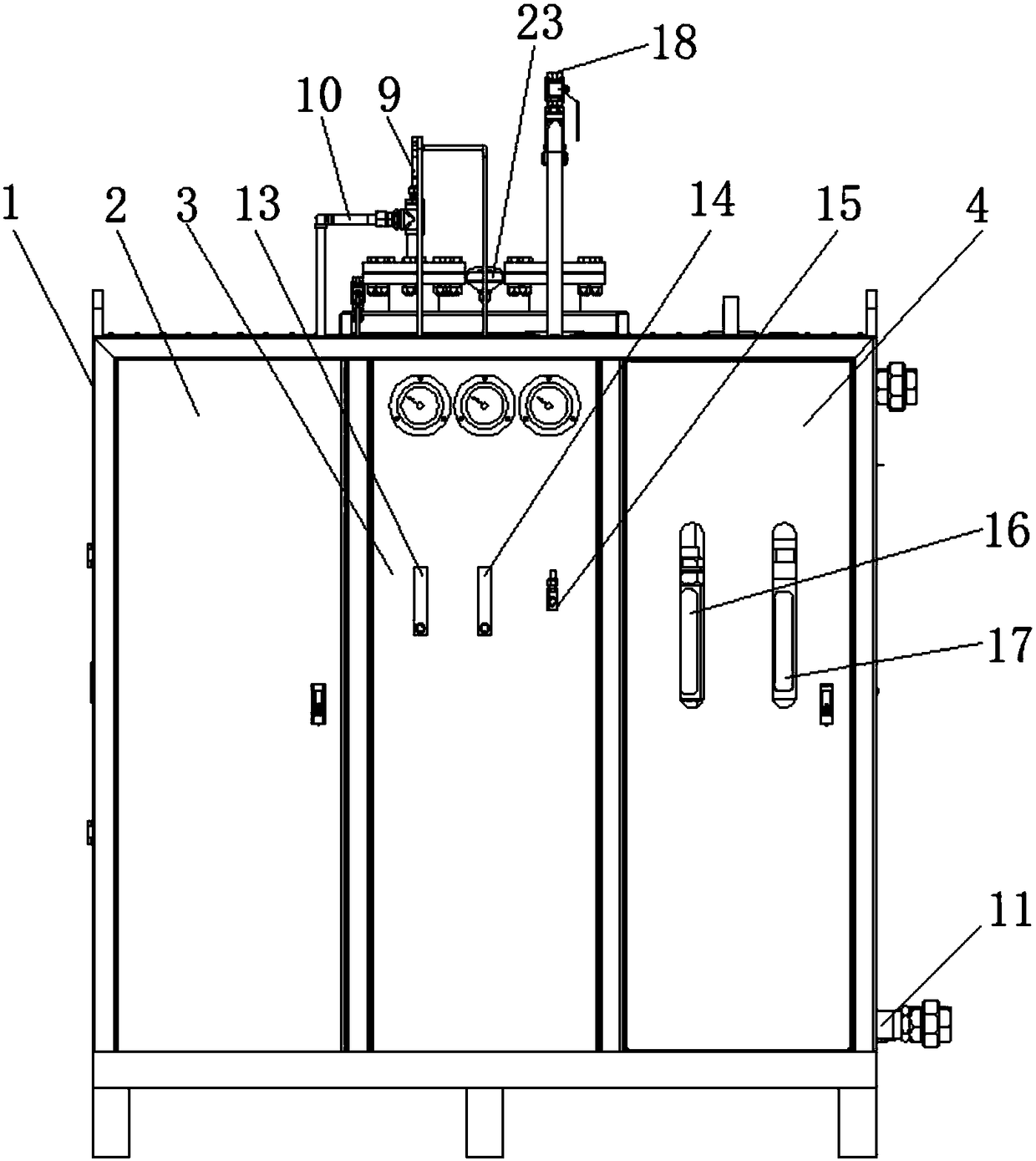

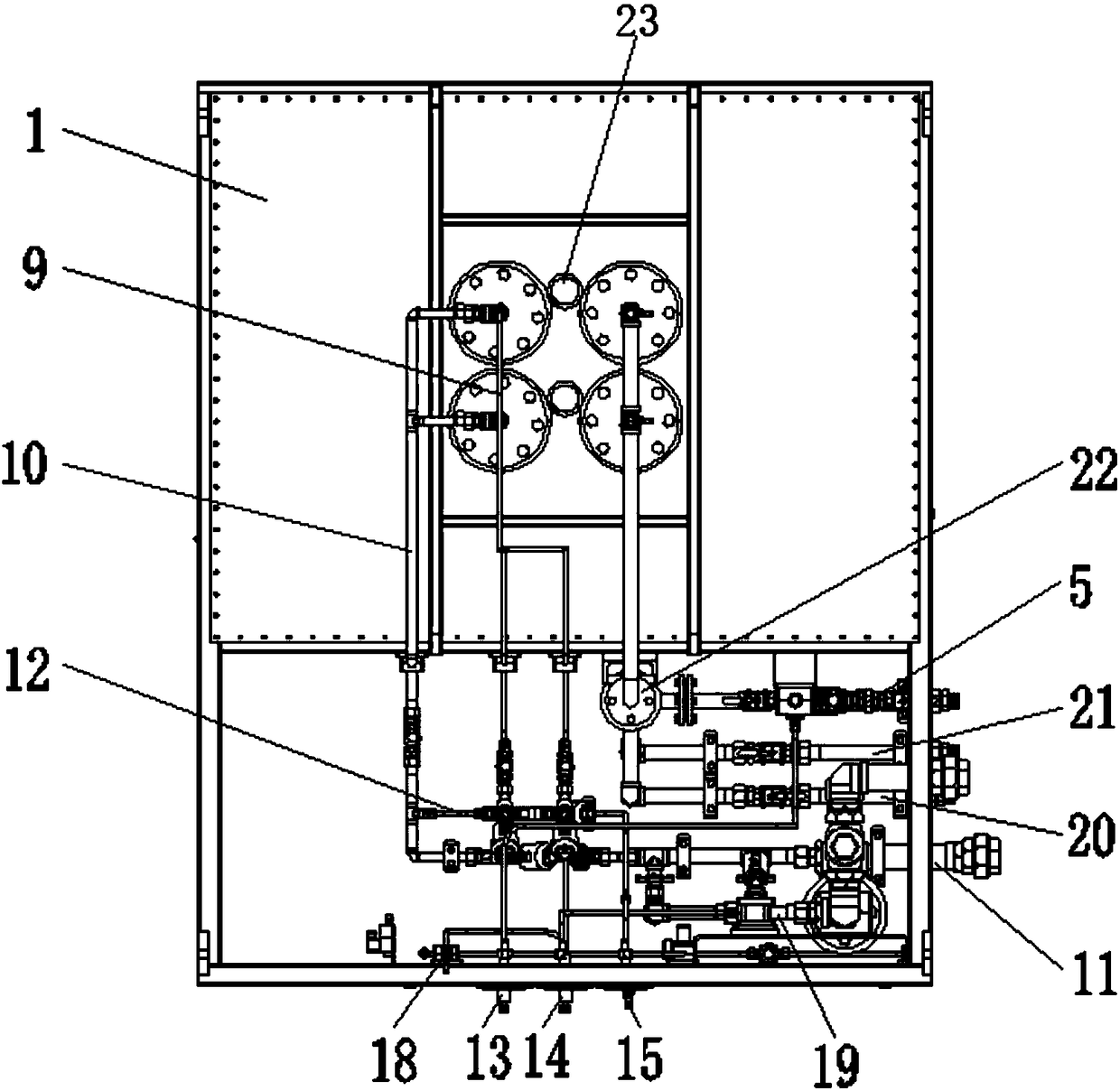

[0024] refer to Figure 1-4 , a high-efficiency methanol pyrolysis furnace with automatic charcoal burning function, comprising a furnace body 1, a thermocouple 23 is arranged on the top of the furnace body 1, a pipeline area is arranged on one side of the furnace body 1, and the pipeline area is far away from the furnace body 1 One side is provided with left door 2, middle door 3 and right door 4 in order from left to right. Pressure gauge A, pressure gauge B and pressure gauge C are installed horizontally on the upper side of middle door 3. Pressure gauge A is for measuring The pressure of the purge air, the pressure gauge B is used to measure the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com