Automatic testing machine for testing internal components of electric toothbrush

An automatic testing machine and electric toothbrush technology, applied in the field of testing machines, can solve problems such as low work efficiency, affecting product quality and output, and being careless, so as to achieve accurate quality of testing products, improve testing efficiency, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

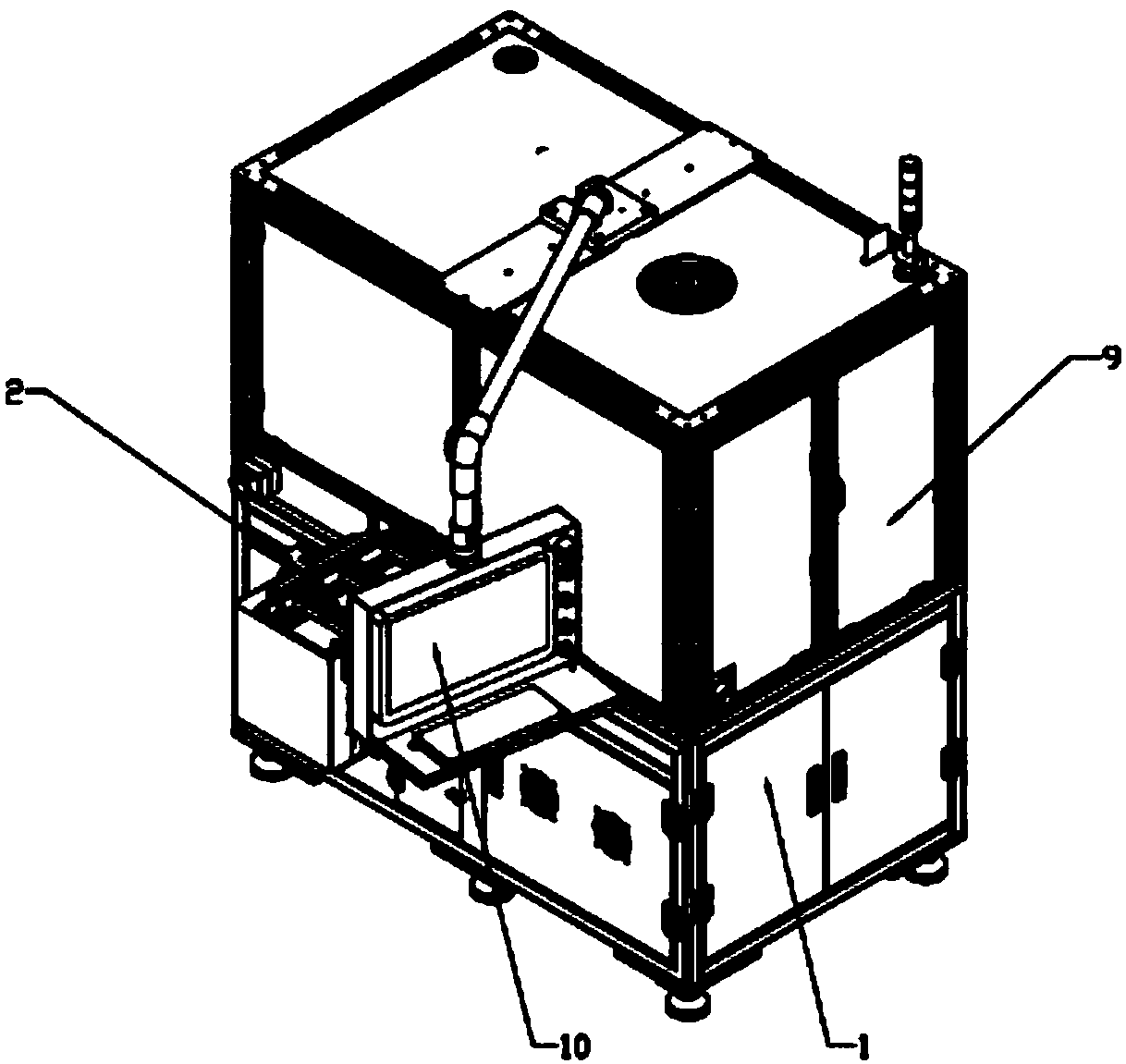

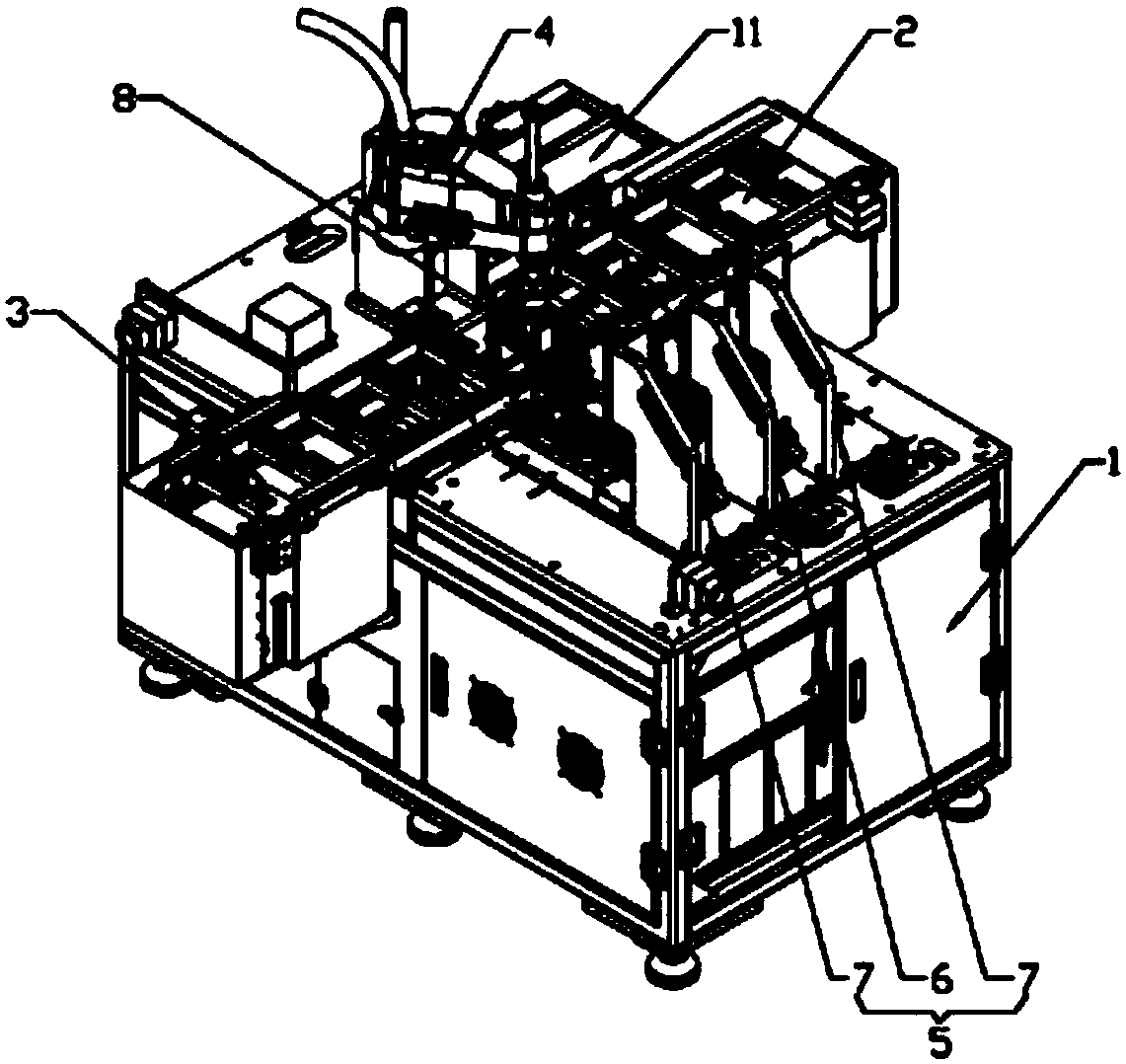

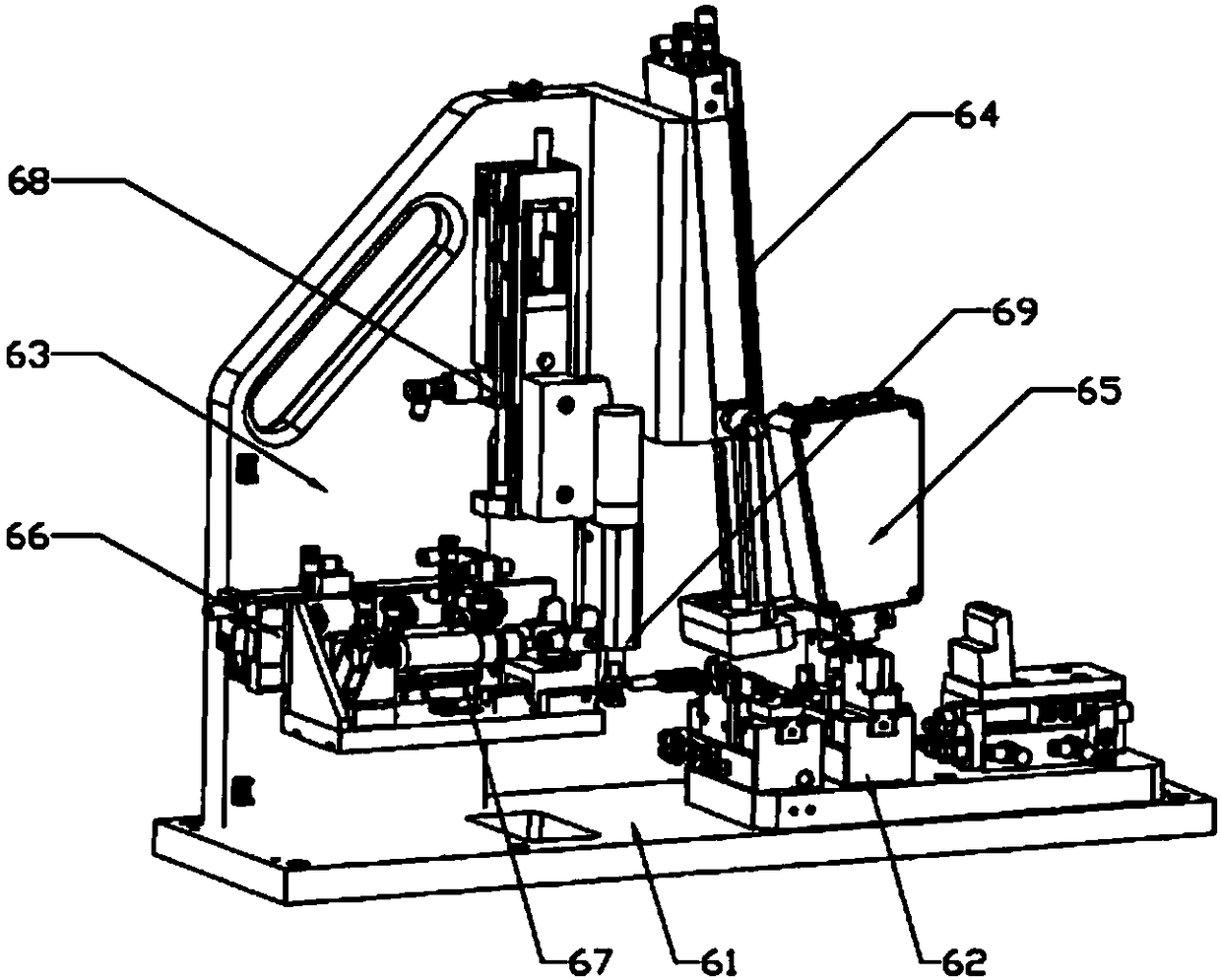

[0017] Such as Figure 1 to Figure 5 As shown, in this embodiment, the present invention includes an equipment base 1, one end of the equipment base 1 is provided with a feeding conveying mechanism 2, and the other end of the equipment base 1 is provided with a discharging conveying mechanism 3, and the feeding conveying mechanism 3 is provided at the other end of the equipment base 1. A robot 4 is provided on one side between the material transfer mechanism 2 and the discharge transfer mechanism 3, and a testing mechanism 5 is provided on the other side between the feed transfer mechanism 2 and the discharge transfer mechanism 3. Described testing mechanism 5 comprises resistance test fixture 6 and the motor function test fixture 7 that is arranged on described resistance test fixture 6 two ends, because the test time on described resistance test fixture 6 is about twice of described motor function test fixture 7, Therefore, the motor function test fixture 7 is provided at bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com