Solid oxide fuel cell coke oven gas power generation process and device

A solid oxide and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as carbon deposition, methane reaction is not easy to complete, battery failure, etc., to reduce the pressure resistance requirements, improve energy efficiency, and reduce investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

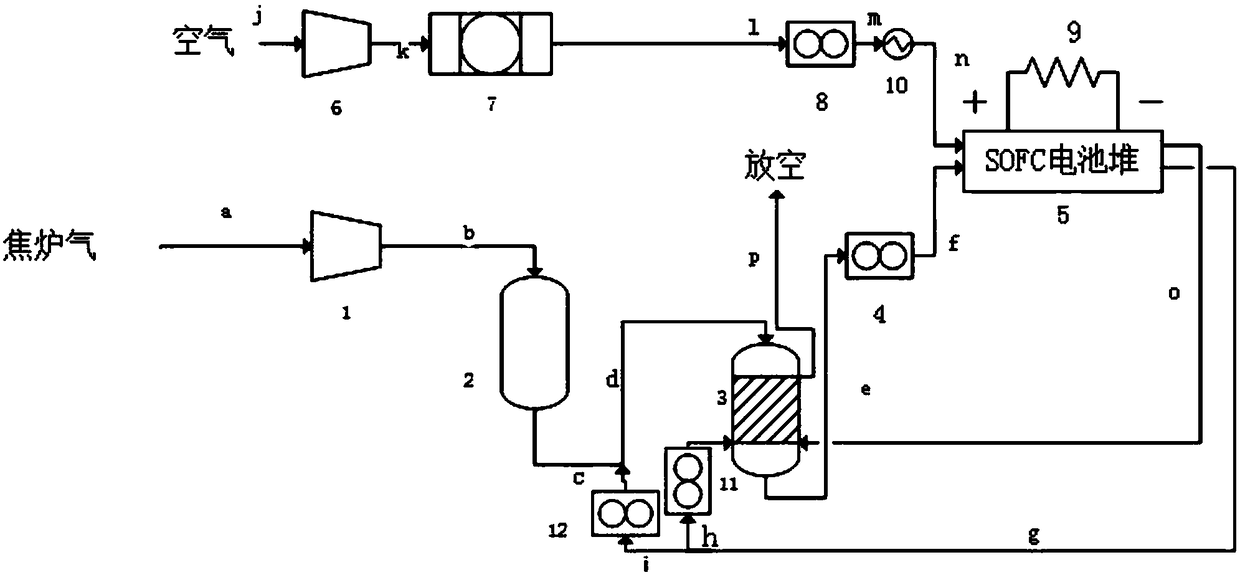

[0035] The air is pressurized to a pressure of 10kPa through the air compressor 6 through the pipeline j, and the air carried out through the air compressor 6 enters the air filter 7 through the pipeline k to remove impurities such as particles in the air, and passes through the buffer tank (not shown in the figure) out) Adjust the pressure to 3.0kPa, through the pipeline 1, the gas flow meter 8 adjusts the gas flow to 10.0m 3 / h flow, and then enter the air side inlet of the SOFC fuel cell stack 5 after heat exchange to 620°C through the heat exchanger 10. Coke oven gas (1.2m 3 / h) After the gas compressor 1, the gas is sent to the buffer tank (not shown in the figure) to adjust the pressure to a pressure of 3.0 MPa so as to be sent to the subsequent section, and then enter the desulfurization device 2 through the pipeline b to remove the coke oven gas Hydrogen sulfide gas (until the content of hydrogen sulfide gas is less than 0.8ppm), enter the methane steam reformer 3 thr...

Embodiment 2

[0038] The air is pressurized to a pressure of 10kPa through the air compressor 6 through the pipeline j, and the air carried out through the air compressor 6 enters the air filter 7 through the pipeline k to remove impurities such as particles in the air, and passes through the buffer tank (not shown in the figure) out) adjust the pressure to 2.5kPa, through the pipeline l, the gas flow meter 8 adjusts the gas flow to 8.0m 3 / h flow, and then enter the air side inlet of the SOFC fuel cell stack 5 after heat exchange to 620°C through the heat exchanger 10. Coke oven gas (1.0m 3 / h) After the gas compressor 1, the gas is compressed to a pressure of 3.0 MPa so as to be transported into the subsequent section, and then enters the desulfurization device 2 through the pipeline b to remove the hydrogen sulfide gas in the coke oven gas (until the hydrogen sulfide gas content is lower than 0.8 ppm), enter the methane steam reformer 3 through pipelines c and d, and the methane steam r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com