Shrimp ferment, and preparation method and application thereof

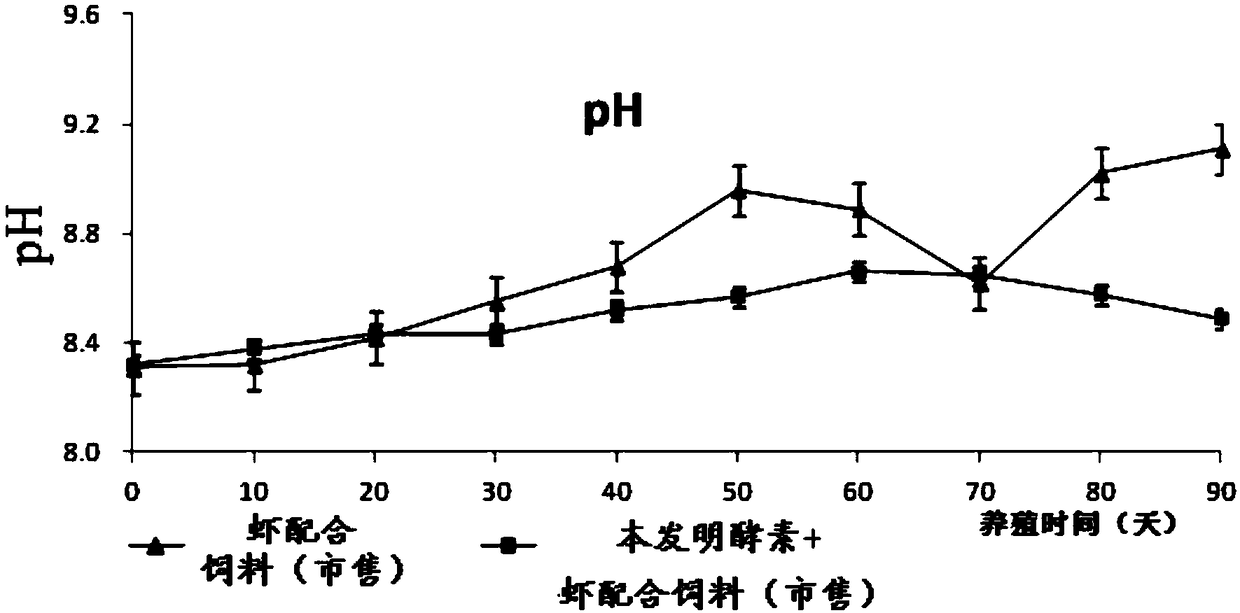

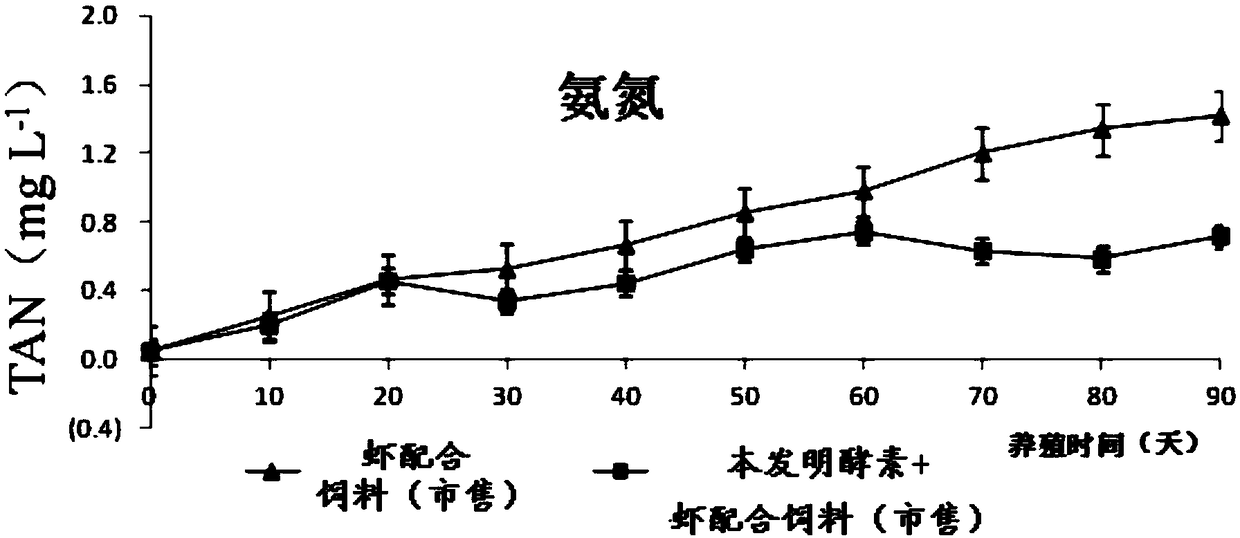

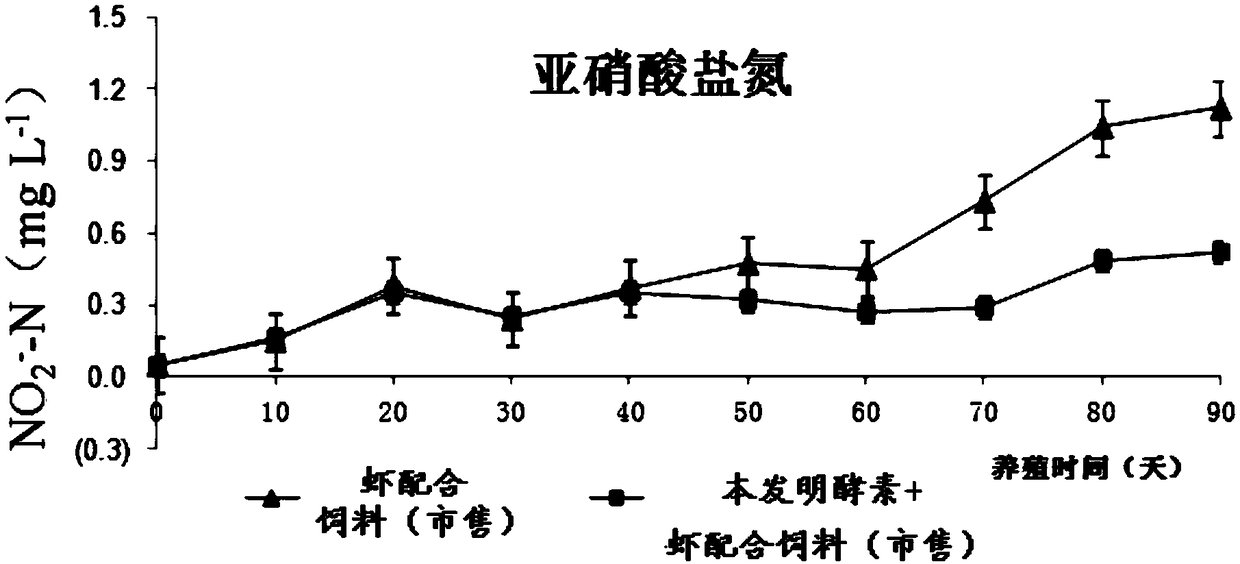

A technology of shrimp enzymes and seeds, applied in the direction of bacteria used in food preparation, application, climate change adaptation, etc., can solve unreasonable fermentation methods and fermentation processes, poor control of raw material fermentation degree, unreasonable proportion of strains, etc. problem, to achieve the effect of improving protein utilization and conversion rate, improving breeding success rate and reducing breeding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention also discloses a preparation method of shrimp enzyme, which comprises the following steps:

[0047] Step 1. Prepare the fermentation bag:

[0048] Step 1.1. Weighing: Weigh the following components according to the mass parts: 75 parts to 85 parts of lactic acid bacteria, 5 parts to 15 parts of bacillus, and 5 parts to 15 parts of yeast;

[0049] Step 1.2. Preparation of starter: take lactic acid bacteria, bacillus and yeast strains for seed culture respectively to prepare lactic acid bacteria seed culture solution, bacillus seed culture solution and yeast seed culture solution;

[0050] Step 1.3. Adopt staged fermentation: add the bacillus seed culture solution and the yeast seed culture solution to the fermentor for aerobic fermentation, control the temperature at 25-35℃ for 10-24 hours, and terminate the fermentation when the OD value is greater than 0.5 ; Then add the lactic acid bacteria seed culture solution to the fermentor for anaerobic fermentation, contr...

Embodiment 1

[0061] A preparation method of shrimp enzyme includes the following steps:

[0062] Step 1. Prepare the fermentation bag:

[0063] Step 1.1. Weighing: Weigh the following components according to mass parts: 80 parts of lactic acid bacteria, 10 parts of bacillus, and 10 parts of yeast;

[0064] Step 1.2. Preparation of starter: take lactic acid bacteria, bacillus and yeast strains for seed culture respectively to prepare lactic acid bacteria seed culture solution, bacillus seed culture solution and yeast seed culture solution;

[0065] Step 1.3. Adopt staged fermentation: add the bacillus seed culture solution and yeast seed culture solution to the fermentor for aerobic fermentation, control the temperature at 30°C for 17 hours, and stop the fermentation when the OD value is greater than 0.5; Add the lactic acid bacteria seed culture solution to the tank, control the temperature at 35°C for 18 hours, and terminate the fermentation when the OD is greater than 0.6 and the pH is less than...

Embodiment 2

[0075] A preparation method of shrimp enzyme includes the following steps:

[0076] Step 1. Prepare the fermentation bag:

[0077] Step 1.1. Weighing: Weigh the following components according to mass parts: 75 parts of lactic acid bacteria, 15 parts of bacillus, and 10 parts of yeast;

[0078] Step 1.2. Preparation of starter: take lactic acid bacteria, bacillus and yeast strains for seed culture respectively to prepare lactic acid bacteria seed culture solution, bacillus seed culture solution and yeast seed culture solution;

[0079] Step 1.3. Adopt staged fermentation: add the bacillus seed culture solution and the yeast seed culture solution to the fermentation tank for aerobic fermentation, control the temperature at 35°C for 10 hours, and terminate the fermentation when the OD value is greater than 0.5; Add the lactic acid bacteria seed culture solution to the tank, control the temperature at 38°C for 12 hours, and terminate the fermentation when the OD is greater than 0.6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com