Discharge basic unit, waste gas purifier and waste gas purification system

An exhaust gas purifier and basic unit technology, applied in chemical instruments and methods, gas treatment, combined devices, etc., can solve the problems of poor exhaust gas treatment effect, low effective energy efficiency, and low degree of integration, and achieve economical technical transformation Improved cost, energy efficiency, and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

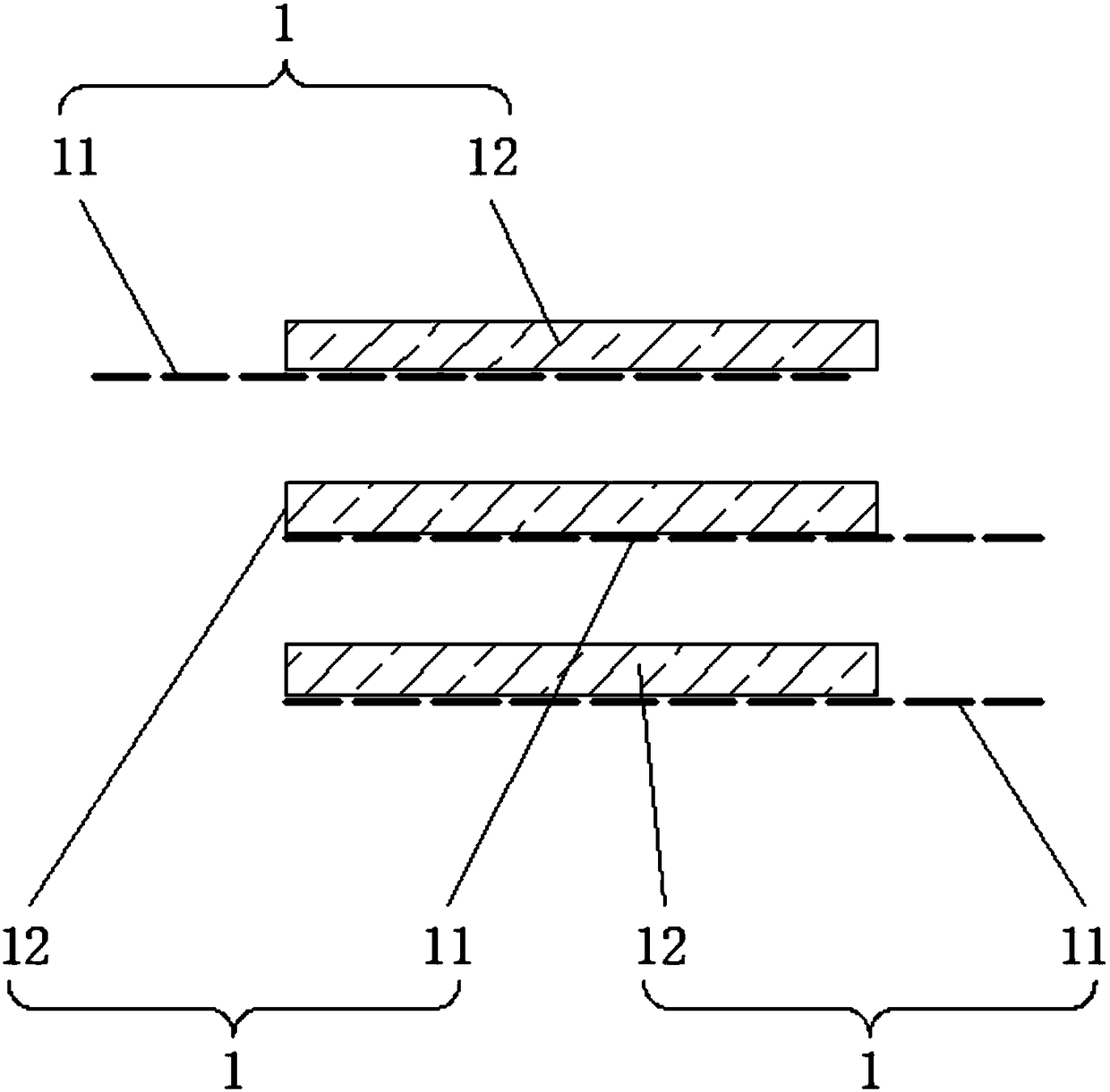

[0041] See figure 1 In the present invention, the discharge basic unit has three electrode assemblies 1; the electrode assembly 1 includes an electrode 11 connected with a wire, and a light-transmitting plate 12 that completely covers the upper surface of the electrode 11; each electrode 11 is a flat plate shape, and is a copper mesh plate, so as to transmit light; each electrode 11 is parallel to each other; each light-transmitting plate 12 is 8mm glass, and the surface of the light-transmitting plate 12 is coated with a catalyst layer with a thickness of 5 μm; the material of the catalyst layer It is an alumina catalyst; the gap between adjacent electrode assemblies 1 forms a discharge space.

[0042] The gap of the discharge space is 20mm.

[0043] The thickness of the electrode 11 is 1mm; the aperture on the electrode 11 is 10mm.

[0044] See Figure 5 with Figure 7 , the exhaust gas purifier in the present invention has a shell 2, and the shell 2 is provided with an ...

Embodiment 2

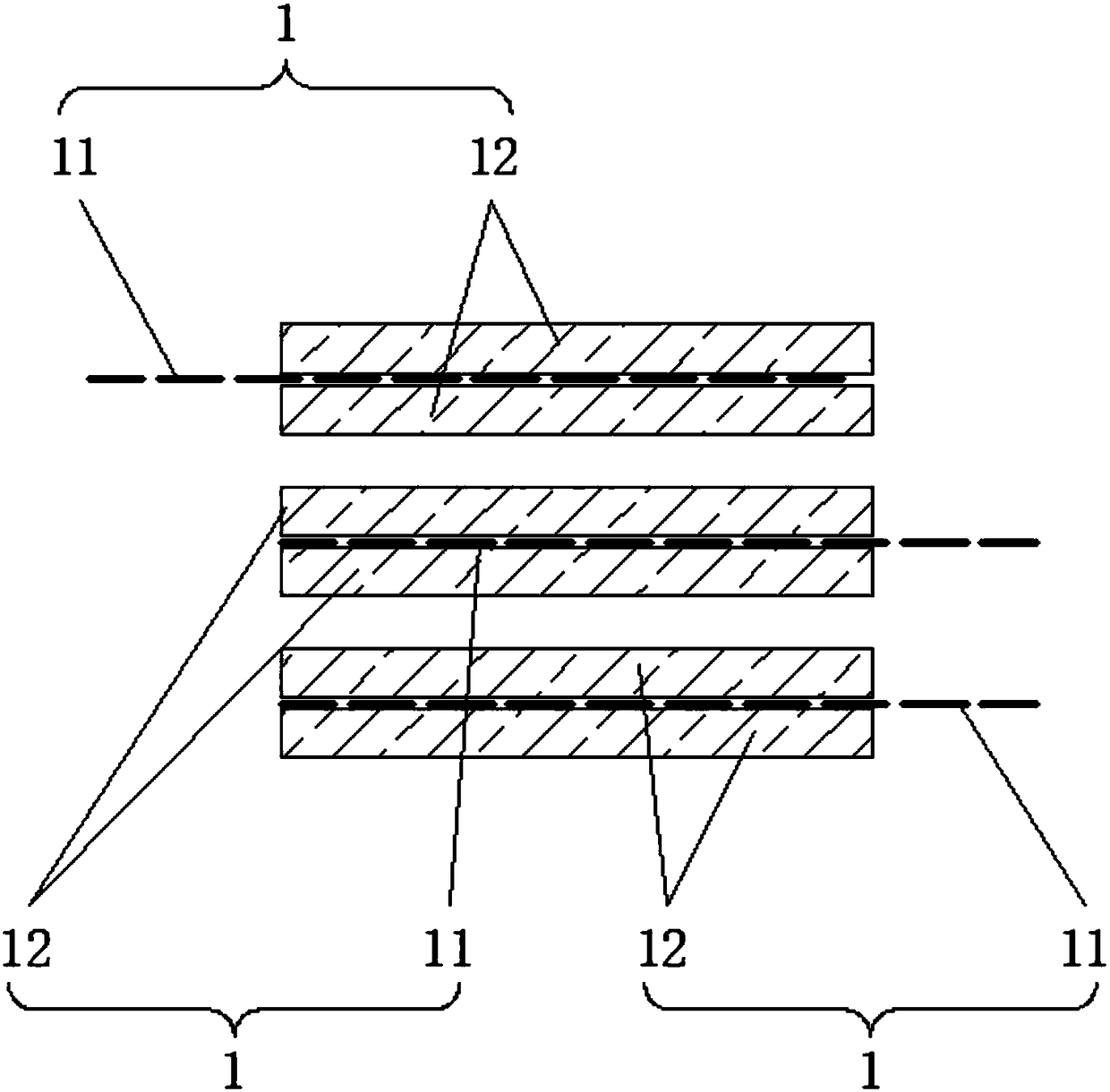

[0054] See figure 2 In the present invention, the discharge basic unit in the present invention has three electrode assemblies 1; the electrode assembly 1 includes an electrode 11 connected with a wire, and a light-transmitting plate 12 that completely covers the upper and lower surfaces of the electrode 11; The electrodes 11 are all in the shape of a flat plate and are porous metal films for light transmission; the electrodes 11 are parallel to each other; each light-transmitting plate 12 is 8mm glass, and the surface of the light-transmitting plate 12 is coated with 0.1 μm thick Catalyst layer; the material of the catalyst layer is calcium; the gap between adjacent electrode assemblies 1 forms a discharge space.

[0055] The gap of the discharge space is 1mm.

[0056] The thickness of the electrode 11 is 0.1mm; the aperture on the electrode 11 is 0.1mm.

[0057] See Figure 7 , the exhaust gas purifier in the present invention has a shell 2, and the shell 2 is provided w...

Embodiment 3

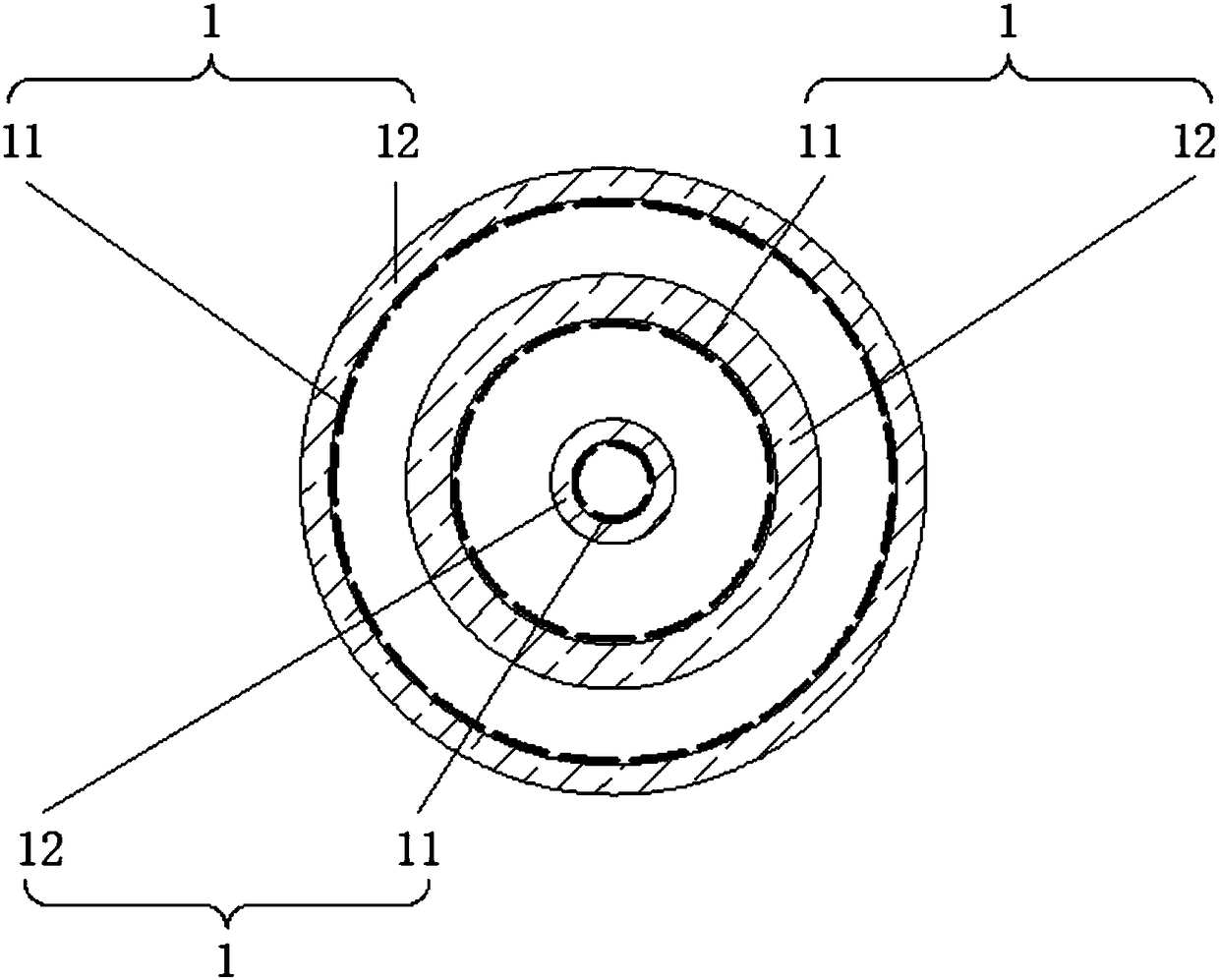

[0067] See image 3 In the present invention, the discharge basic unit has three electrode assemblies 1; the electrode assembly 1 includes an electrode 11 connected with a wire, and a light-transmitting plate 12 that completely covers the upper surface of the electrode 11; each electrode 11 is in the form of a sleeve. Cylindrical, and copper mesh, in order to transmit light; each electrode 11 is parallel to each other; each light-transmitting plate 12 is organic glass, and the surface of the light-transmitting plate 12 is coated with a catalyst layer with a thickness of 3 μm; the material of the catalyst layer For composite alumina and cobalt oxide; the gap between adjacent electrode assemblies 1 forms a discharge space.

[0068] The gap of the discharge space is 10mm.

[0069] The thickness of the electrode 11 is 0.5mm; the aperture on the electrode 11 is 6mm.

[0070] See Figure 6 and Figure 7 , the exhaust gas purifier in the present invention has a shell 2, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com