Intelligent insulin syringe production line

A production line and insulin technology, which is applied in the field of assembly line, can solve the problems of labor-intensive physics, increase of production cost, and inability to meet the processing requirements of insulin syringes, and achieve the effect of avoiding cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings:

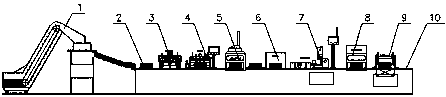

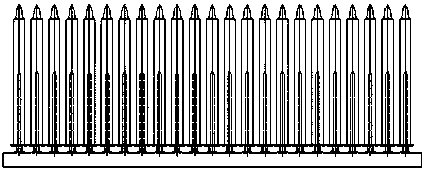

[0028] like figure 1 and 3 As shown in the figure, the present invention includes a guide rail 10, and the guide rail 10 is sequentially provided with a needle barrel discharging automatic transmission mechanism 1, an upper needle tube mechanism, a needle tube dispensing mechanism, an ultraviolet UV glue curing needle mechanism, a needle spray silicone oil mechanism, and automatic image recognition. The kick-off mechanism, the needle sheath automatic assembling mechanism and the finished product unloading mechanism are all provided with a needle-cylinder placing and clamping template 2, and the needle-cylinder placing and clamping template 2 is fixed on the guide rail 10, and the needle Cylinder placement clamping template 2 is a plurality of positioning rods arranged in a row.

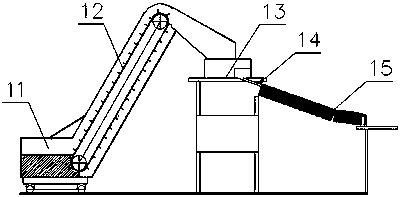

[0029] like figure 2 As shown in the figure, the automatic conveying mechanism for dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com