Organic/inorganic heavy-metal production waste water treatment method based on up-to-stand discharge

A technology for producing wastewater and treatment methods, which is applied in water/sewage treatment, special compound water treatment, water/sewage multi-stage treatment, etc. Effects of improving biodegradability, stabilizing emission standards, and reducing the presence of complexed heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

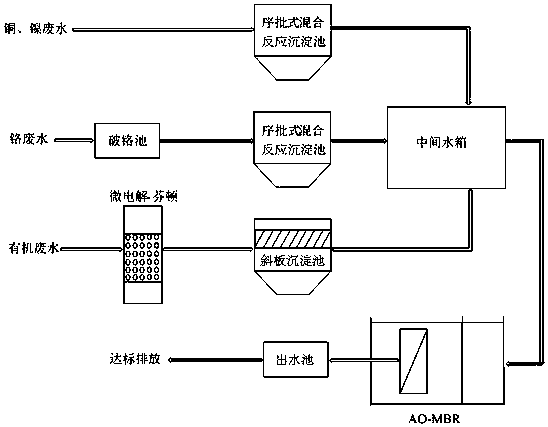

[0031] The present invention provides a method for treating organic and inorganic heavy metal production wastewater with standard discharge as the core. The method adopts a method of classified collection and classified treatment of production wastewater in electroplating parks, such as figure 1 As shown, the specific steps are as follows:

[0032] 1. The copper and nickel wastewater is chemically precipitated to remove most of the heavy metals through the sequencing batch mixed reaction sedimentation tank, and the effluent enters the intermediate water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com