Ablation-resistant ternary dissipation agent and application

A technology of dissipating agent and ablation resistance, which is used in ablation-resistant dissipating agents and application fields, can solve the problems of low dissipative agent content and high linear ablation rate, achieve good heat dissipation, improve infiltration rate, Good protective effect of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Embodiment 1: The ablation-resistant ternary dissipative agent in this embodiment includes 4-8 parts by mass of aluminum powder, 11-14 parts of silicon powder and 1-3 parts of boron powder.

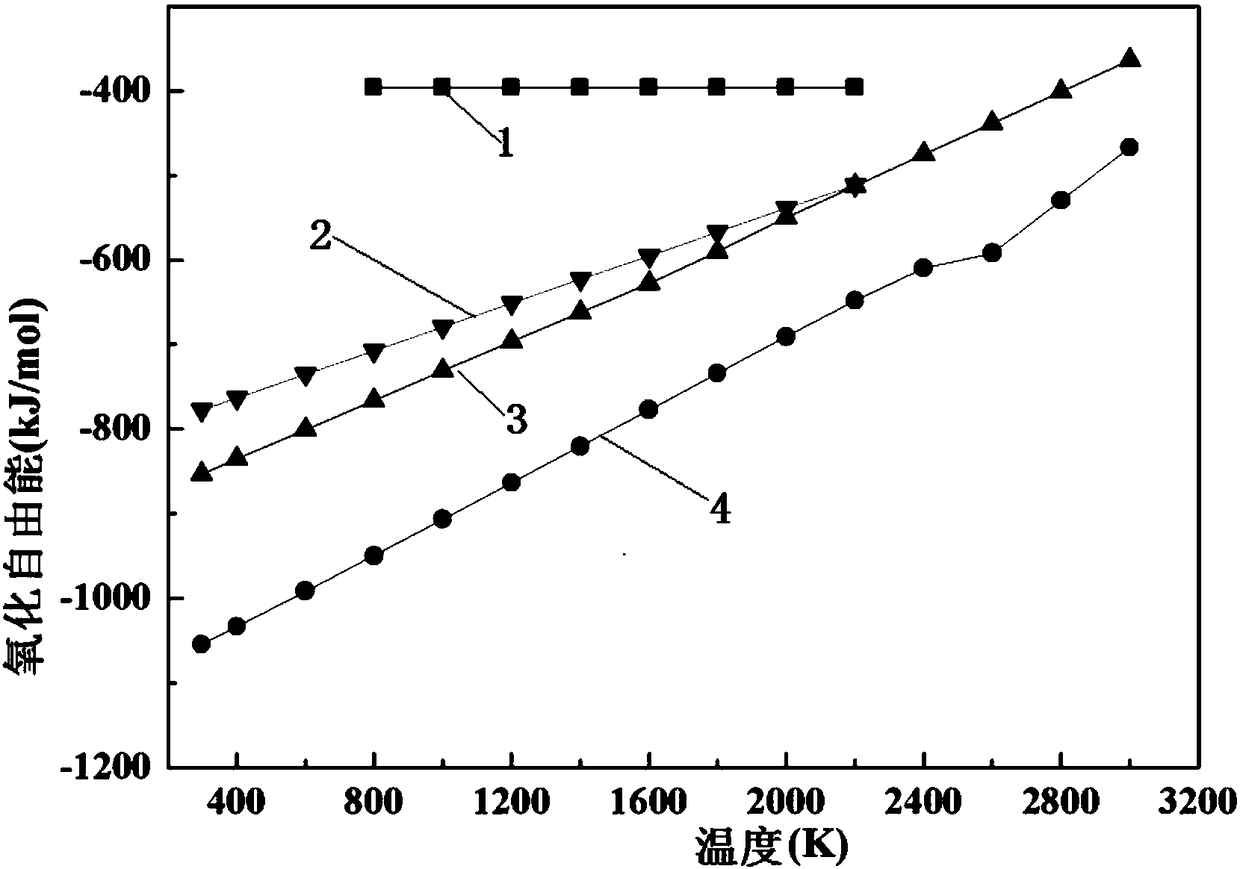

[0027] The principles and beneficial effects of this embodiment are:

[0028] 1. The ablation-resistant ternary dissipative agent in this embodiment has a higher melting point than the aluminum-silicon binary dissipative agent, and can adapt to higher temperature ablation environments; the addition of boron can improve the The wettability of the powder and the substrate improves the infiltration rate, and forms a liquid ceramic protective layer with greater adhesion on the surface of the substrate in an ablation environment, which resists air erosion and better protects the substrate; and boron has a high melting latent heat and latent heat of vaporization, which can play a good role in heat dissipation; the physical properties of the alloy components of the ablation-resistant tern...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that: the particle diameter of the aluminum powder is <3 mm; the particle diameter of the silicon powder is <3 mm; and the particle diameter of the boron powder is <3 mm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0032] Specific Embodiment Three: The application of the ablation-resistant ternary dissipative agent in the preparation of dissipative and heat-resistant composite materials in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com