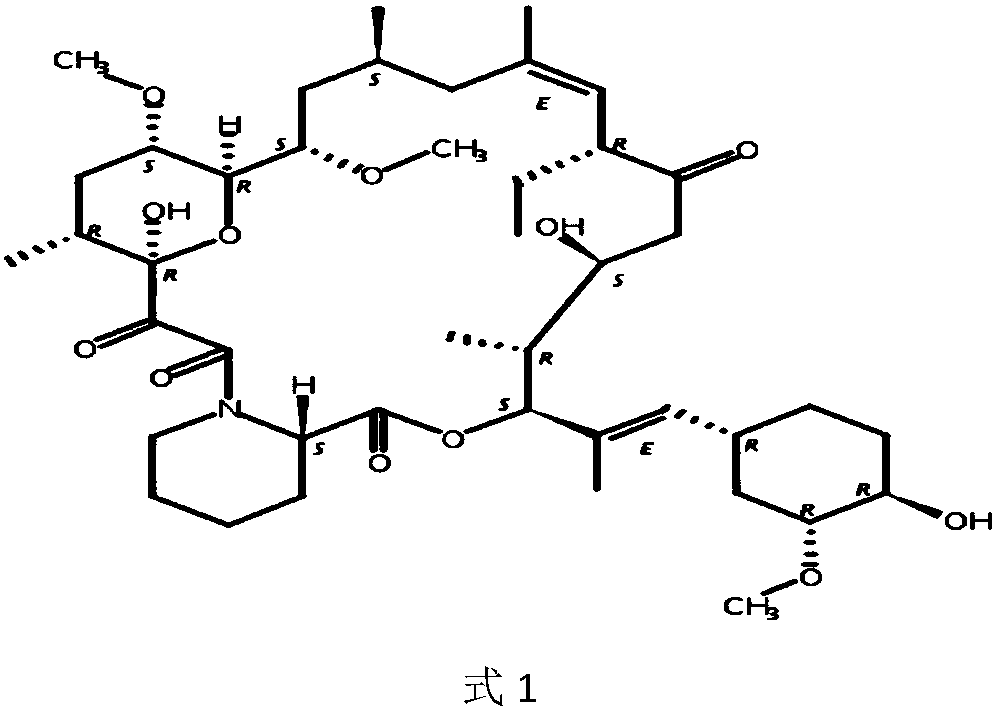

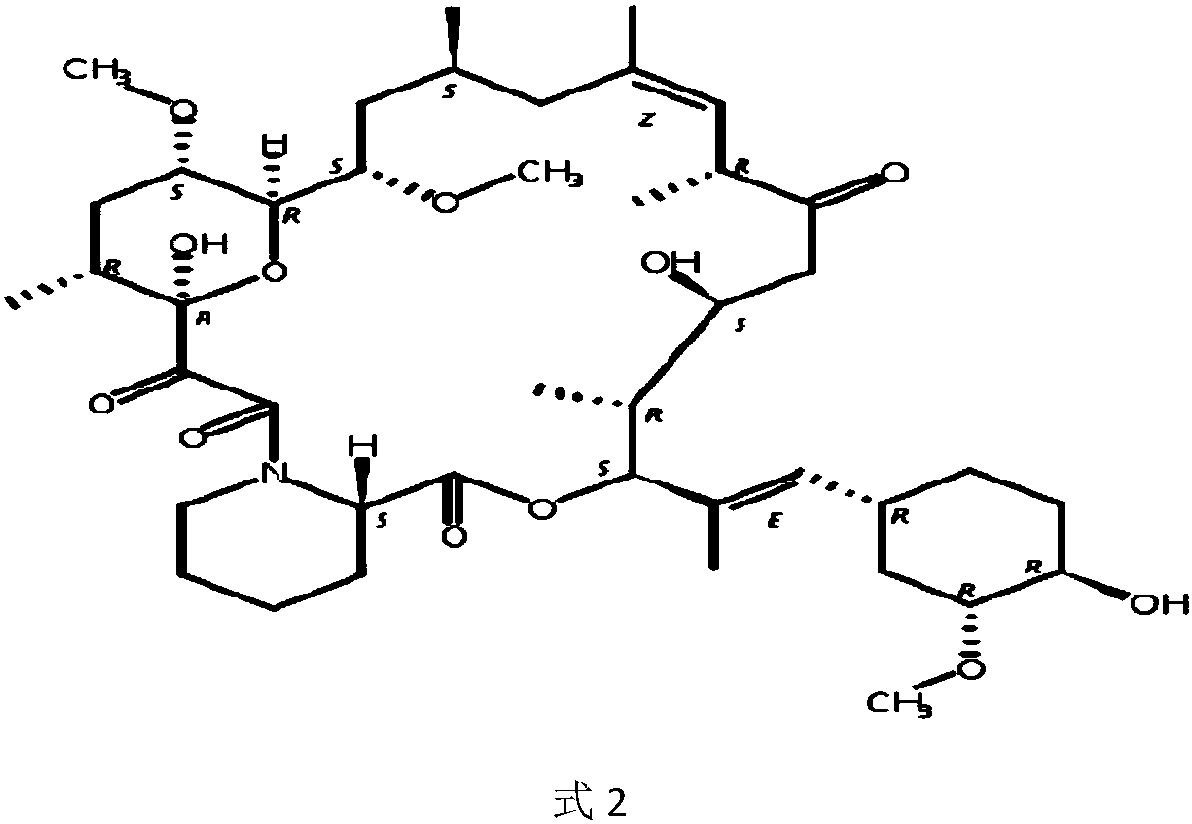

Purification method for ascomycin

A technology of ascomycin and purification method, applied in the field of biopharmaceuticals, can solve the problems of rare extraction and purification of ascomycin, occupation, etc., and achieve the effects of easy industrial production, quality assurance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Get 6.0g ascomycin crude product (ascomycin chromatographic purity 67.2%, FK523 chromatographic purity 6.6%), dissolve with ethanol to 500mL to obtain sample solution, use the macroporous adsorption resin column that model is XAD-1600N to carry out dynamic adsorption, put The column flow rate is 0.5BV / h, the desorption mobile phase is 85% (mL / mL) ethanol aqueous solution, the elution flow rate is 1.0BV / h, and the liquid phase detection is used after every 0.5BV collection; Combined, concentrated under reduced pressure at 36°C until no liquid dripped out, then added 1L of ethyl acetate for extraction, then concentrated the ethyl acetate extract phase at 36°C under reduced pressure to obtain 3.7 g of dry powder. Dissolve the obtained dry powder with 46 mL of acetonitrile with a weight-to-volume ratio of about 8:100 (g / mL). After dissolving and clarifying, 49 mL of column liquid is obtained. The concentration of ascomycin detected by liquid phase is 58 mg / mL. The upper col...

Embodiment 2

[0028] Take 5.7g of ascomycin crude product (ascomycin chromatographic purity 64.7%, FK523 chromatographic purity 6.5%), dissolve it with ethanol to 500mL to obtain a sample solution, and use a model XAD-1600N macroporous adsorption resin column to carry out dynamic adsorption. The column flow rate is 0.5BV / h, the desorption mobile phase is 75% (mL / mL) ethanol aqueous solution, the elution flow rate is 1.0BV / h, and the liquid phase detection is used after every 0.5BV collection; Combined, concentrated under reduced pressure at 39°C until no liquid dripped out, then added 1L of ethyl acetate for extraction, then concentrated the ethyl acetate extract phase under reduced pressure at 39°C to obtain 3.8 g of dry powder. Dissolve the obtained dry powder with 63 mL of acetonitrile with a weight-to-volume ratio of about 6:100 (g / mL). After dissolving and clarifying, 65 mL of column liquid is obtained. The concentration of ascomycin detected by liquid phase is 44.6 mg / mL. The upper co...

Embodiment 3

[0030]Take 6.5g of ascomycin crude product (ascomycin chromatographic purity 67.6%, FK523 chromatographic purity 6.4%), dissolve with ethanol to 500mL to obtain sample solution, use the macroporous adsorption resin column that model is XAD-1600N to carry out dynamic adsorption, put The column flow rate is 0.5BV / h, the desorption mobile phase is 90% (mL / mL) ethanol aqueous solution, the elution flow rate is 1.0BV / h, and every 0.5BV is collected and detected by liquid phase; Combined, concentrated under reduced pressure at 39°C until no liquid dripped out, then added 1L of ethyl acetate for extraction, then concentrated the ethyl acetate extract phase at 39°C under reduced pressure to obtain 4.1 g of dry powder. Dissolve the obtained dry powder with 46 mL of acetonitrile with a weight-to-volume ratio of 9:100 (g / mL). After dissolving and clarifying, 48 mL of column liquid is obtained. The concentration of ascomycin detected by liquid phase is 66.3 mg / mL. The upper column liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com