Asphalt composition prepared by utilizing macromolecules

A technology of asphalt composition and polymer, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of waste of resources, road performance that cannot meet the requirements of national standards, and white garbage that cannot be recycled, so as to reduce waste Interference of air bubbles, good viscous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

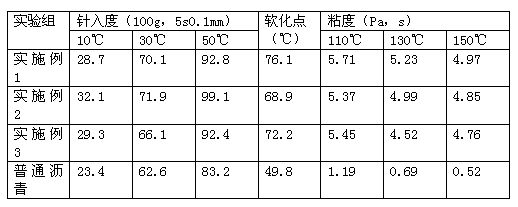

Embodiment 1

[0023] The technical scheme of this embodiment is as follows, a kind of asphalt composition prepared by utilizing polymers, the product of this embodiment includes the following components in parts by weight: 200 parts of bio-asphalt, 80 parts of petroleum asphalt, 60 parts of plasticizer, 50 parts of waste rubber powder, 40 parts of waste plastic, 70 parts of coal tar pitch, 40 parts of stabilizer, 35 parts of defoamer, 45 parts of tackifying resin.

[0024] The bio-asphalt in this embodiment is made from animal heavy oil, the stabilizer is SEAM, the defoamer is butyl phosphate defoamer, and the softening point of the tackifying resin is 90°C-100°C.

[0025] A kind of preparation method of the bituminous composition that utilizes macromolecule preparation of the present embodiment, specific preparation method is as follows:

[0026] (1) Take 50 parts of waste rubber powder, 40 parts of waste plastics, 70 parts of coal tar pitch, mix with 200 parts of raw bio asphalt, and 80 p...

Embodiment 2

[0030] The technical scheme of this embodiment is as follows, a bituminous composition prepared by using polymers, including the following components in parts by weight: 100 parts of bio-asphalt, 100 parts of petroleum asphalt, 40 parts of plasticizer, 60 parts of waste rubber powder , 30 parts of waste plastic, 100 parts of coal tar pitch, 30 parts of stabilizer, 50 parts of defoamer, and 30 parts of tackifying resin.

[0031] The bio-asphalt in this example is made from animal heavy oil, the stabilizer is SEAM, the defoamer is butyl phosphate defoamer, and the softening point of the tackifying resin is 100°C.

[0032] A kind of preparation method of the bituminous composition that utilizes macromolecule preparation of the present embodiment, specific preparation method is as follows:

[0033] (1) Take 60 parts of waste rubber powder, 30 parts of waste plastics, 100 parts of coal tar pitch, mix and shear with 100 parts of bio asphalt and 100 parts of petroleum pitch for 30 mi...

Embodiment 3

[0037] The technical scheme of this embodiment is as follows, a bituminous composition prepared by using polymers, including the following components in parts by weight: 300 parts of bio-asphalt, 50 parts of petroleum asphalt, 80 parts of plasticizer, 40 parts of waste rubber powder , 50 parts of waste plastic, 50 parts of coal tar pitch, 50 parts of stabilizer, 20 parts of defoamer, and 60 parts of tackifying resin.

[0038] The bio-asphalt in this example is made from animal heavy oil, the stabilizer is SEAM, the defoamer is butyl phosphate defoamer, and the softening point of the tackifying resin is 90°C.

[0039] A kind of preparation method of the bituminous composition that utilizes macromolecule preparation of the present embodiment, specific preparation method is as follows:

[0040] (1) Take 40 parts of waste rubber powder, 50 parts of waste plastics, 50 parts of coal tar pitch, mix with 300 parts of biological asphalt, and 50 parts of petroleum asphalt, and mix and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com