Quantum dot, preparation method thereof and application thereof

A technology of quantum dots and core-shell quantum dots, applied in the field of quantum dot materials, can solve the problems of low fluorescence efficiency and achieve high quantum yield, narrow half-peak width, and high crystal purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

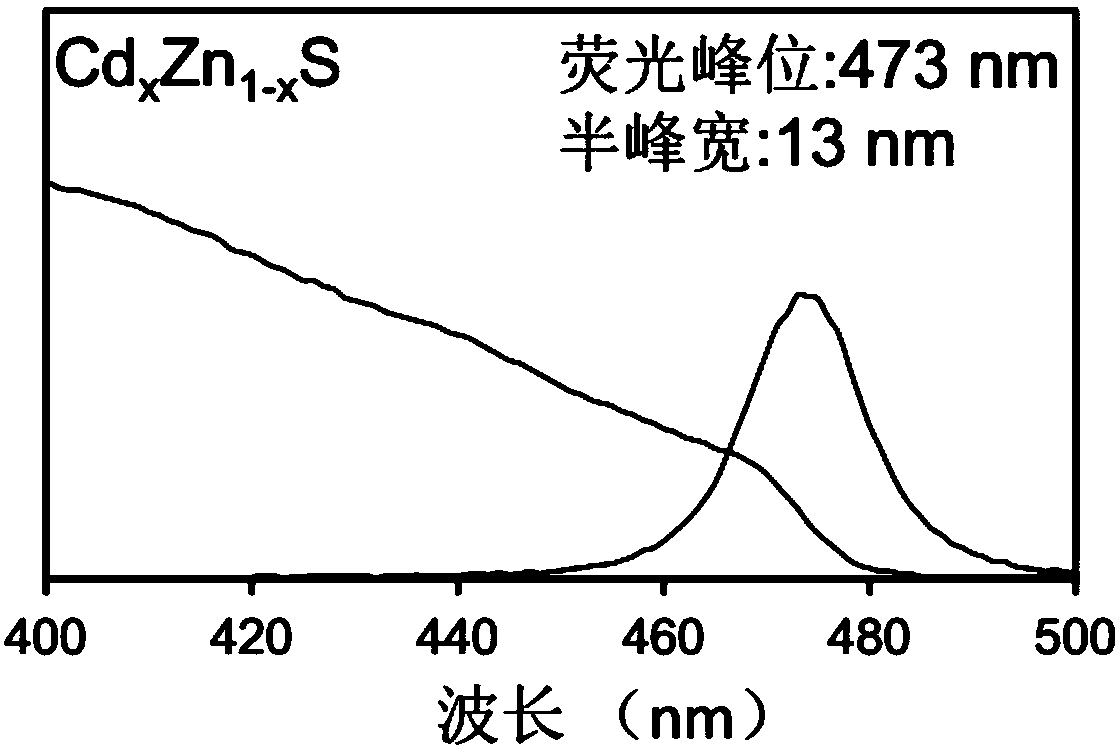

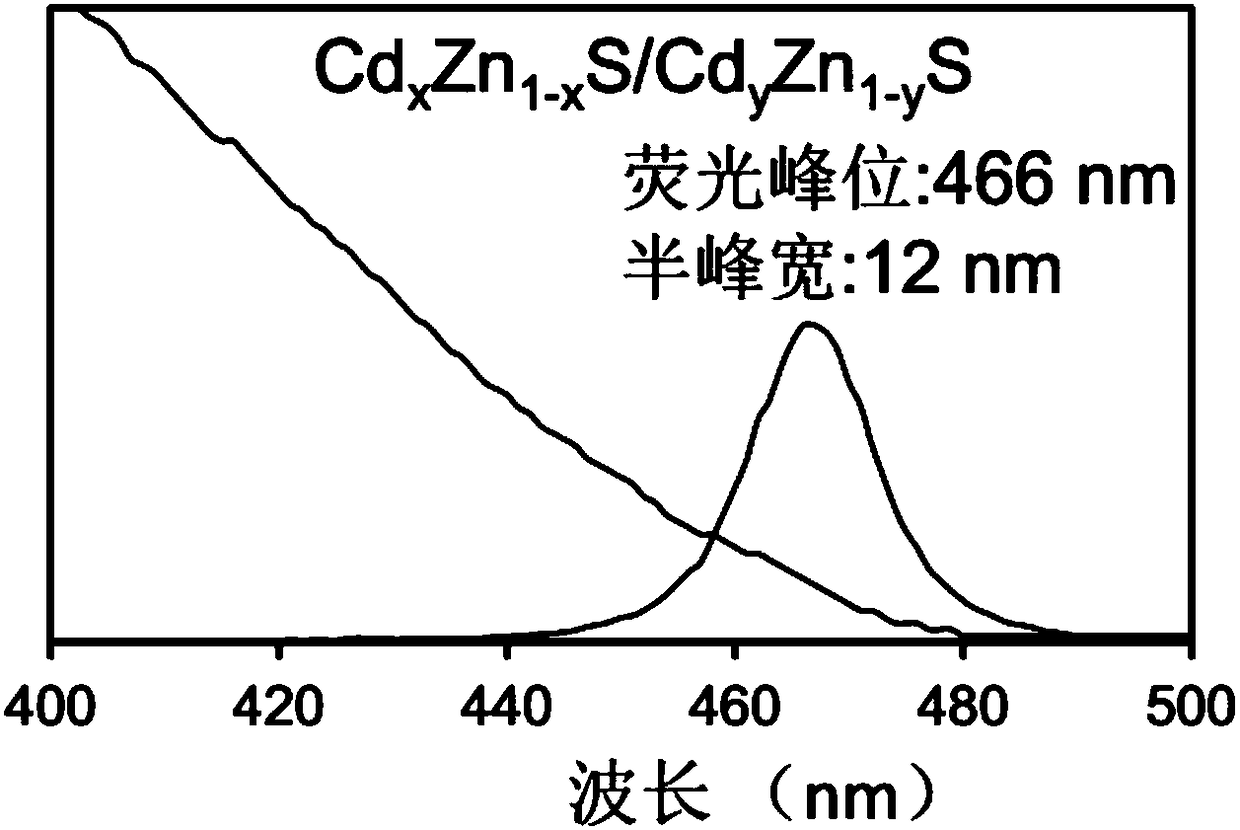

[0032] In a typical implementation of the present application, a method for preparing quantum dots is provided, the preparation method comprising: step S1, providing a mixed precursor of a zinc-containing precursor and a cadmium-containing precursor, wherein the mixed precursor contains zinc The molar ratio of cadmium is greater than or equal to 10; step S2, reacting the first sulfur precursor and the mixed precursor to obtain a CdS / ZnS core-shell quantum dot system; step S3, performing alloying treatment on the CdS / ZnS core-shell quantum dot system to obtain Contains Cd x Zn 1-x S quantum dot system; And step S4, to containing Cd x Zn 1-x Adding cadmium carboxylate and the second sulfur precursor to the S quantum dot system to grow the shell to obtain Cd x Zn 1-x S / Cd Y Zn 1-Y S core-shell quantum dots, where 0<X<1, 0<Y<1.

[0033] The above preparation method first forms CdS / ZnS core-shell quantum dots, and then performs alloying treatment to form CdS / ZnS x Zn 1-x S...

Embodiment 1

[0057] Cd x Zn 1-x S / Cd Y Zn 1-Y Synthesis of S (mixed ligand, shell doped cadmium content is 12.5% of the sulfur precursor used when coating) core-shell quantum dots: weigh CdO (0.0512g, 0.4mmol), dodecanoic acid (3.3g, 16mmol), basic zinc carbonate (0.66g, 1.2mmol), and 12mL ODE were mixed in a 100mL three-necked flask. After exhausting with an inert gas for 10 minutes, the temperature was raised to 280°C to obtain a clear solution (ie, the mixed precursor) . Cool the clear solution to 250°C, inject 3mL0.2mmol / mL (S-ODE) into it, and react for 5 minutes (that is, to obtain the CdS / ZnS core-shell quantum dot system); then add 6mmol oleic acid, and raise the temperature to 300°C, carry out the alloying reaction for 30 minutes, then add 1mL TBP, and react for 10 minutes to obtain a Cd-containing x Zn 1-x S nuclear quantum dot system. Cd x Zn 1-x S nuclear quantum dot system was added dropwise at a speed of 6mL / h 20mL 0.2mmol / mL S-TBP, 5mL oleic acid and 2.5mL 0.2mmol...

Embodiment 2

[0059] The difference from Example 1 is that the clear solution was cooled to 220°C, and 3mL of 0.2mmol / mL (S-ODE) was injected into it, and reacted for 20 minutes (that is, a CdS / ZnS core-shell quantum dot system was obtained).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com