Photonic crystal preparation method and photonic crystal prepared by method

A photonic crystal and liquid technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of low preparation efficiency, limited structure, and many defects in photonic crystals, and achieve the effects of high preparation efficiency, low cost, and wide source of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a kind of preparation method of photonic crystal, this method comprises the following steps:

[0036] (1) providing an emulsion containing at least one monodisperse particle, at least one surfactant and at least one solvent;

[0037] (2) Apply the emulsion to the surface of the substrate that needs to form photonic crystals to form a liquid pattern on the surface, and the contact angle of the emulsion to the surface of the substrate that needs to form photonic crystals is 30° to 120°, preferably 40° to 60°, more preferably 40° to 50°; and

[0038] (3) drying the substrate with the liquid pattern to remove the solvent in the liquid pattern to obtain a photonic crystal.

[0039] In the present invention, "at least one kind" means one kind or two or more kinds.

[0040] The monodisperse particles have a light refractive index different from that of air, and may be monodisperse particles commonly used in the field of photonic crystal preparation, wh...

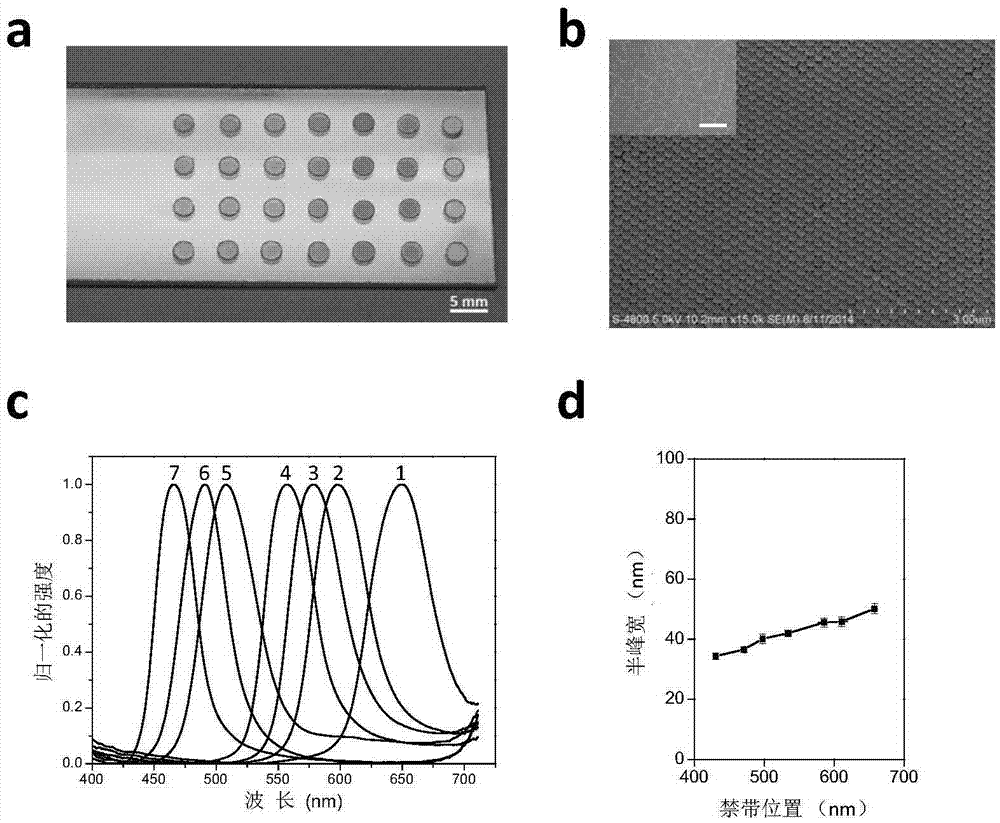

Embodiment 1

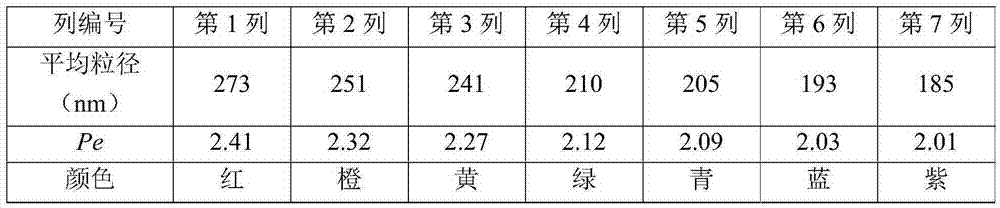

[0113] Monodisperse polystyrene particles of different particle sizes (as shown in Table 1) (synthesized with reference to the method of CN100381872C embodiment 1, wherein, adopt styrene as monomer) and sodium lauryl sulfate and water (water in The dynamic viscosity at 70°C is 0.8×10 -3 Pa·s, the same below) is mixed and emulsified by ultrasonic method to obtain an emulsion. In each emulsion, relative to 100 parts by weight of water, the content of monodisperse polystyrene particles is 2 parts by weight, relative to 100 parts by weight Monodisperse polystyrene particles, the content of sodium lauryl sulfate is 2×10 -5 parts by weight. Use a pipette gun to drop the emulsion on the surface of the glass sheet (the contact angle of the emulsion on the glass sheet surface is 45°) to form a 4×7 emulsion drop lattice (the drop volume of each point is 5 μL, and one emulsion forms a lattice In one column, the particle diameter of the monodisperse polystyrene particles in the emulsion...

Embodiment 2

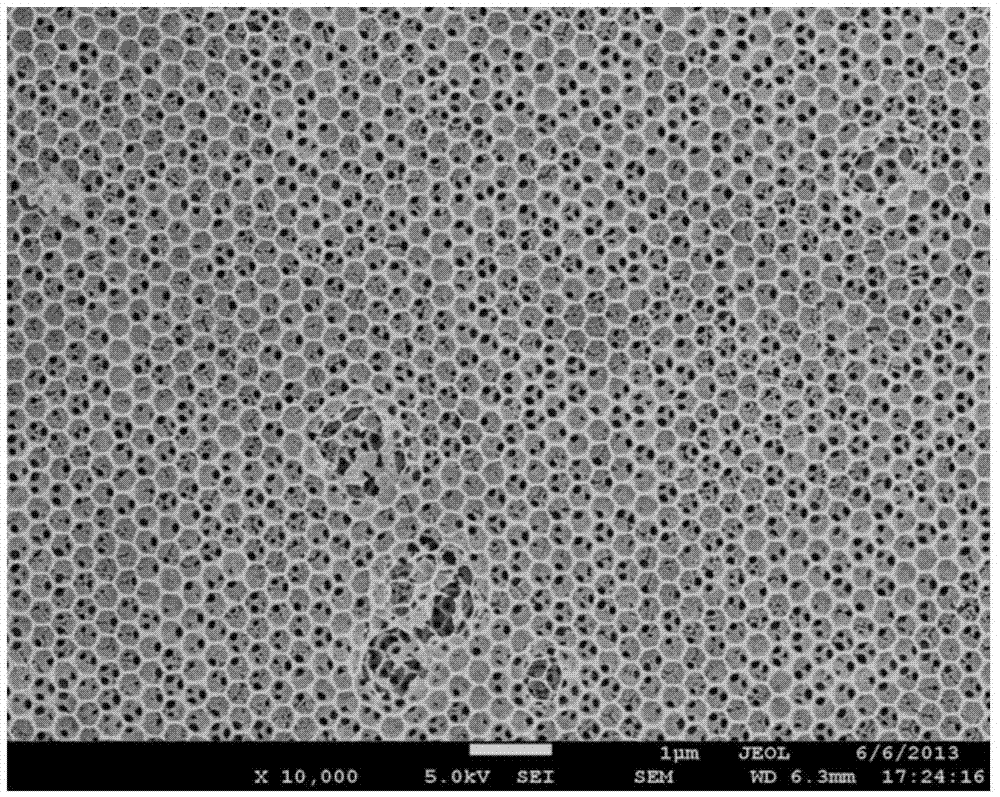

[0121] Monodispersed polystyrene particles with a particle diameter of about 220nm (synthesized with reference to the method of CN100381872C embodiment 1, wherein styrene is used as a monomer), sodium lauryl sulfate and water are mixed and emulsified by ultrasonic methods, thereby Obtain the emulsion, wherein, relative to 100 parts by weight of water, the content of monodisperse polystyrene particles is 2 parts by weight, relative to 100 parts by weight of monodisperse polystyrene particles, the content of sodium lauryl sulfate is 1 * 10 -5 parts by weight.

[0122] The following methods are used to carry out hydrophilic and hydrophobic patterning treatment on part of the surface of the silicon wafer:

[0123] Vacuum vapor deposition of 1H,1H,2H,2H-perfluorodecyltrimethoxysilane on the surface of a silicon wafer forms a monomolecular hydrophobic layer, and then irradiates with a 200W UV mask for 8 hours to form a hydrophilic pattern. On the silicon wafer surface treated with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com