Rose aromatic grape wine processing equipment, rose aromatic grape wine processing method and prepared grape wine

A processing equipment and wine technology, which is applied in the field of wine processing, can solve the problems of soft and natural fragrance, and the inability to coordinate and integrate the rose fragrance of wine aroma components, and can not be reflected. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

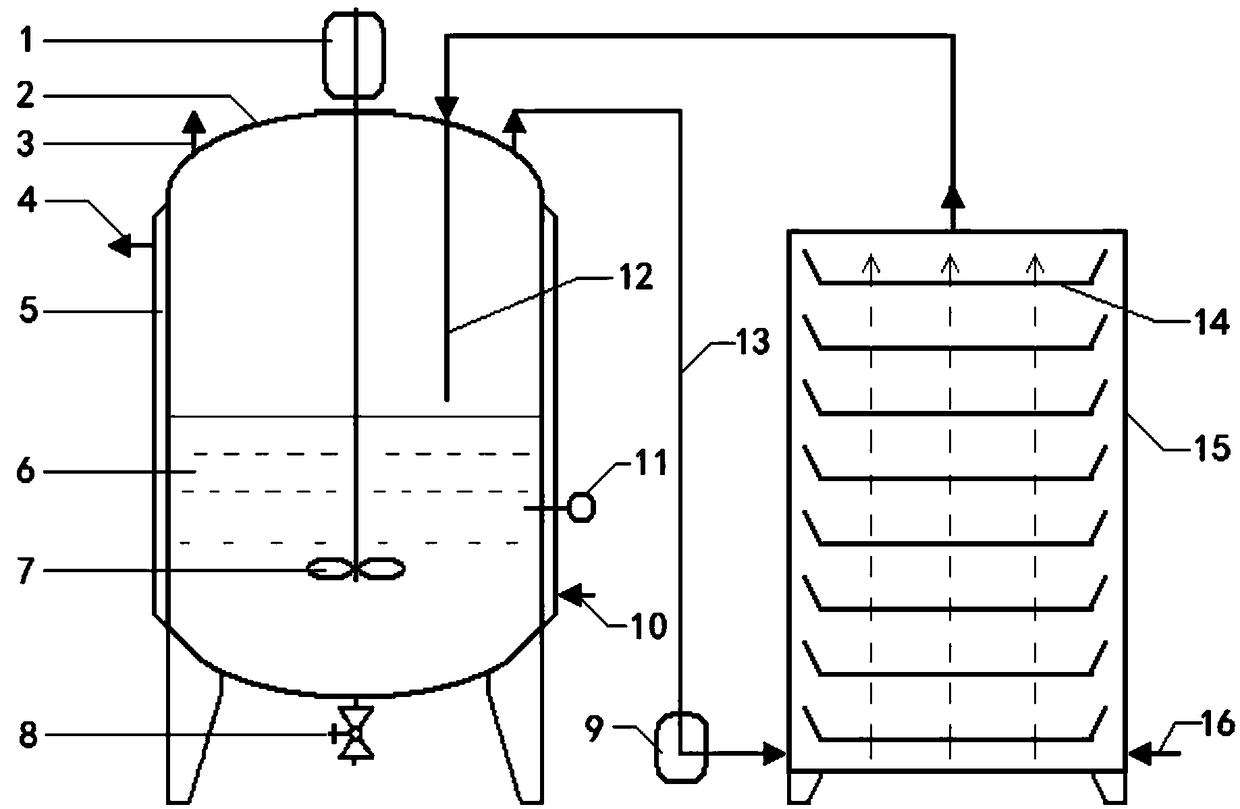

[0044] Rose aromatherapy wine processing equipment

[0045] The specific structure is as figure 1 As shown, the speed regulating motor (1), absorption tank (2), exhaust port (3), refrigerant outlet (4), refrigerant jacket (5), wine liquid (6), stirring paddle (7), outlet Wine valve (8), gas circulation pump (9), refrigerant inlet (10), temperature controller (11), aroma introduction pipe (12), air return pipe (13), flower tray (14), sealed cabinet (15) , Carbon dioxide filling port (16). 8 layers of plastic flower trays are arranged in the airtight cabinet, and there are multiple air holes at the bottom of the flower tray, and the flower tray is placed on a stainless steel shelf.

Embodiment 2

[0047] Utilize the method in the equipment processing rose scented wine in embodiment 1

[0048] Put 70L of red wine in the absorption tank, feed refrigerant into the refrigerant jacket of the absorption tank, keep the temperature in the absorption tank at 4-6°C, spread 14kg of roses collected in the morning on the 8th floor of the sealed cabinet On the flower tray, close the sealed cabinet door, fill the sealed cabinet and absorption tank with carbon dioxide gas through the carbon dioxide inflation port before the rose aromatherapy wine processing equipment works, and exhaust the air in the closed system from the exhaust port, and fill the entire equipment system with Carbon dioxide, close the carbon dioxide gas filling port and exhaust port to form a closed gas circuit cycle, and turn on the gas circulation pump to circulate the carbon dioxide gas in the equipment system. The flow rate of carbon dioxide gas is 13L / min; after the carbon dioxide gas is introduced, the stirring...

Embodiment 3

[0050] Utilize the method in the equipment processing rose scented wine in embodiment 1

[0051] Put 300L of red wine in the absorption tank, feed the refrigerant into the refrigerant jacket of the absorption tank, keep the temperature in the absorption tank at 10-14°C, spread 60kg of roses collected in the morning on the 20th floor of the sealed cabinet On the blooming plate, fill the sealed cabinet and absorption tank with carbon dioxide gas through the carbon dioxide charging port before the equipment works, remove the air in the closed system from the exhaust port, and fill the entire equipment system with carbon dioxide, close the carbon dioxide charging port and exhaust The mouth forms a closed gas circuit cycle, and the gas circulation pump is turned on to circulate the carbon dioxide gas in the equipment system. The flow rate is 20L / min; the stirring paddle of the absorption tank is started, and the stirring speed is 50rpm; the wine circulates to absorb the aroma compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com