Steel shot tempering device

A technology of tempering device and steel shot, which is applied in the direction of furnace, furnace type, heat treatment equipment, etc., can solve the problems that embrittlement cannot be eliminated, embrittlement is easy to occur, and the comprehensive mechanical properties of steel shot are reduced, so as to achieve better adhesion effect, Avoid the accumulation of silicon powder and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

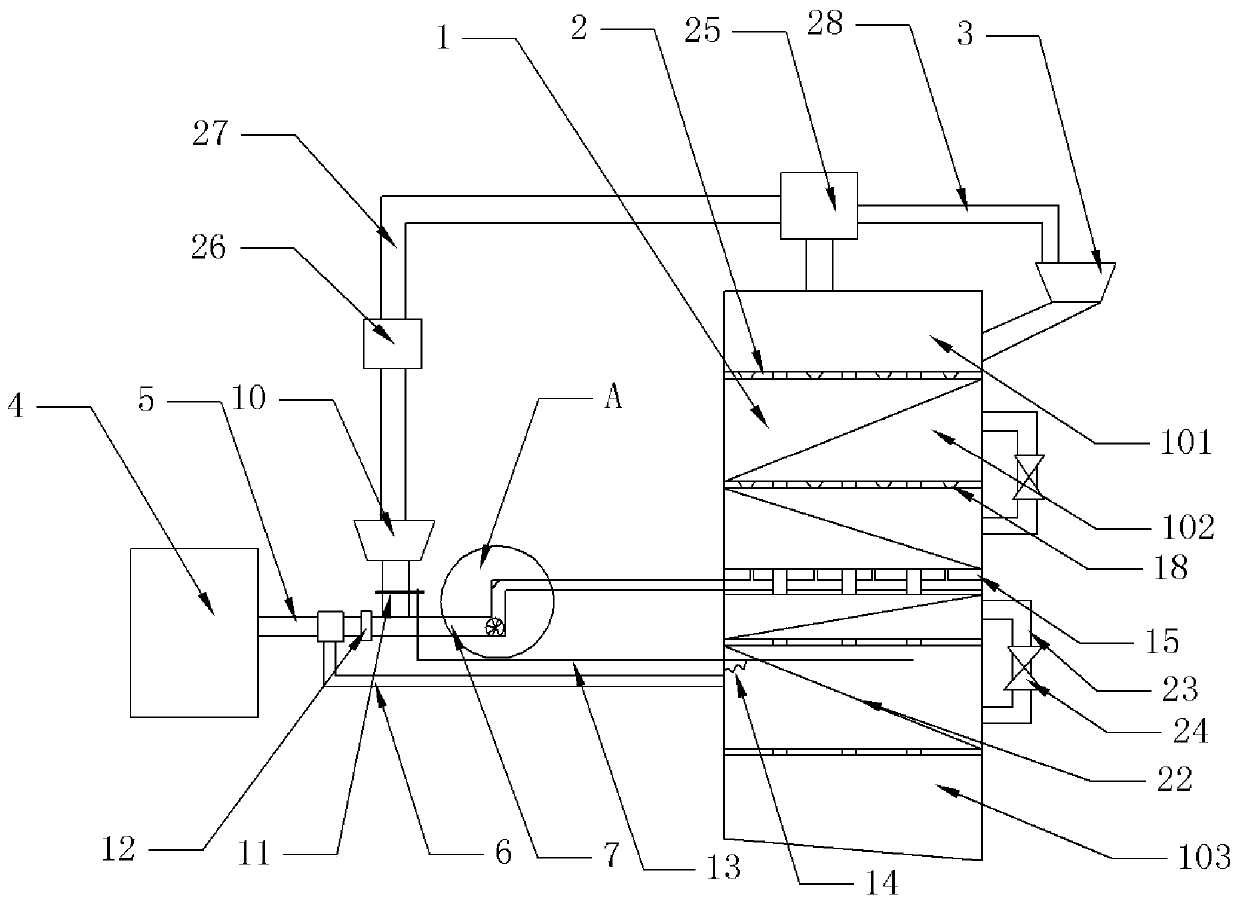

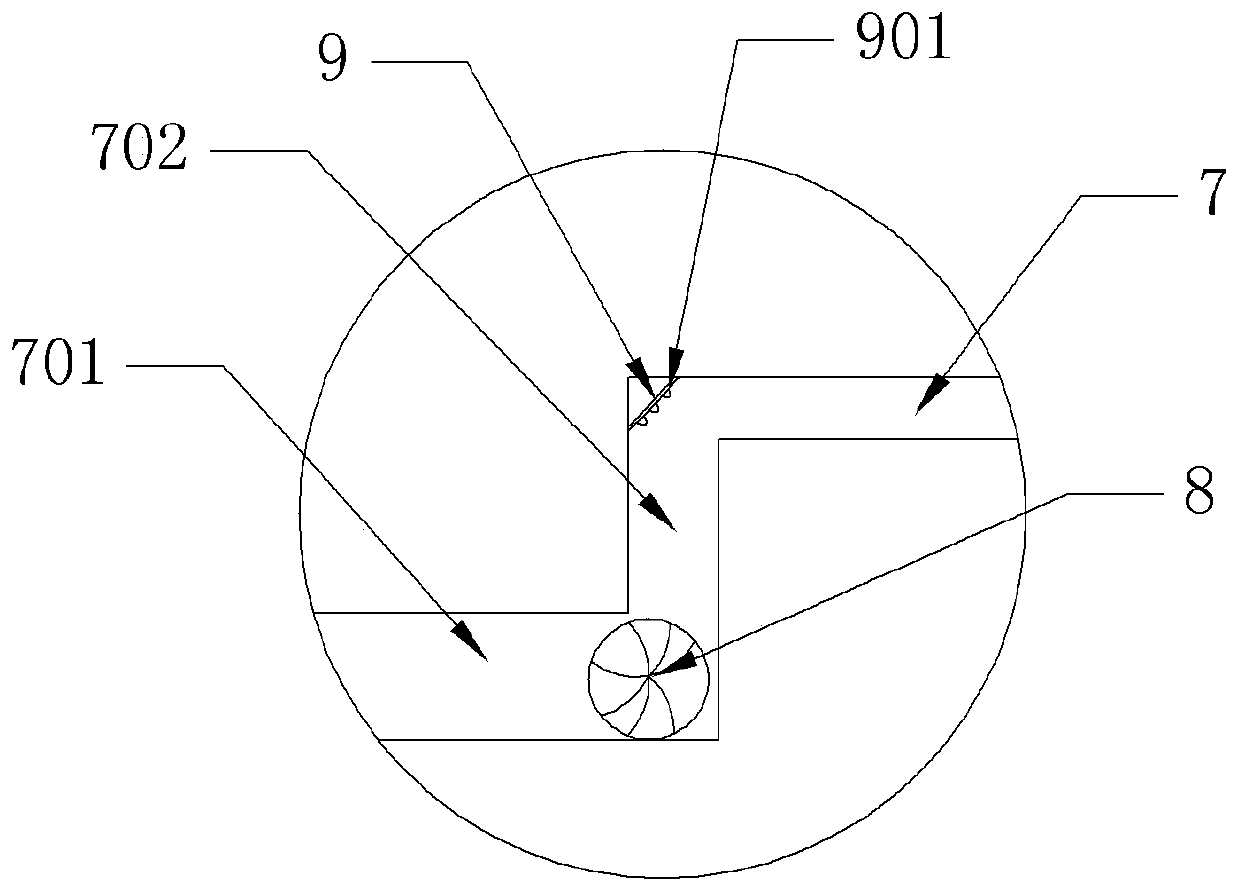

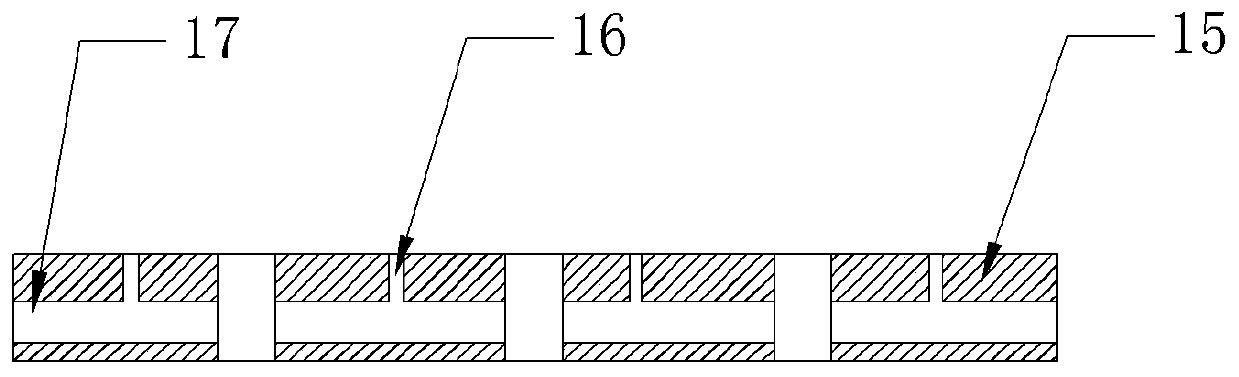

[0026] Example 1, such as figure 1Shown: a steel shot tempering device, including a furnace body 1, inside the furnace body 1 from top to bottom are a feeding chamber 101, two tempering chambers 102 and a collection chamber 103, these chambers pass through four compartments The plates 2 are divided, and each partition 2 is installed horizontally on the inner wall of the furnace body 1 . The upper right side of the furnace body 1 is equipped with a feed hopper 3, the upper end of the feed hopper is in a normally closed state, the feed hopper 3 communicates with the feed chamber 101 of the furnace body 1, and a Hot blast stove 4, the right outer wall of hot blast stove 4 is threadedly connected with a main pipe 5, and the free end of main pipe 5 is equipped with three-way pipe joint, and the bottom of main pipe 5 is provided with the hot-blast pipe 6 that is installed on the three-way pipe joint, and the hot-blast pipe The free end of 6 communicates with the tempering chamber 1...

Embodiment 2

[0028] Embodiment 2 is different from Embodiment 1 in that the shape of the buffer plate 9 is arc-shaped.

[0029] For practical application, refer to figure 1 , when the steel shot is tempered, first the high-temperature and high-pressure gas in the hot blast stove 4 is passed into the main pipe 5, and a part of the hot blast reaches the tempering chamber 102 at the bottom through the hot blast pipe 6. When the pressure reaches the pressure relief valve 24 set When the value is fixed, the tempering chamber 102 at the bottom will release hot air into the tempering chamber 102 on the upper layer, thereby gradually releasing the pressure upwards. Since the corresponding pressure in the pressure relief valve 24 is getting smaller and smaller, each tempering chamber The temperature inside 102 also gradually decreased. Put the quenched steel shot into the feeding hopper 3, the steel shot enters the feeding chamber 101 of the furnace body 1 through the feeding hopper 3, and the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com