Zirconium-based amorphous alloy and preparation method thereof

A zirconium-based amorphous alloy and amorphous alloy technology, applied in the field of new metal materials, can solve the problems of increasing cost, failing to deoxidize and deoxidizing nitrogen, and lacking effective solutions, so as to improve the forming ability and reduce burning. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

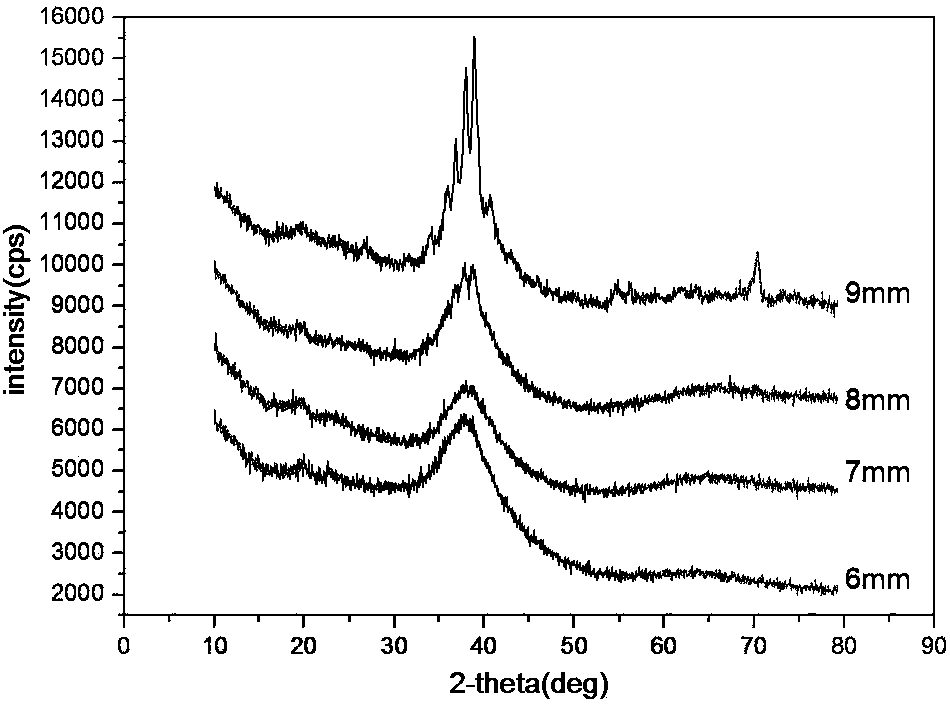

Image

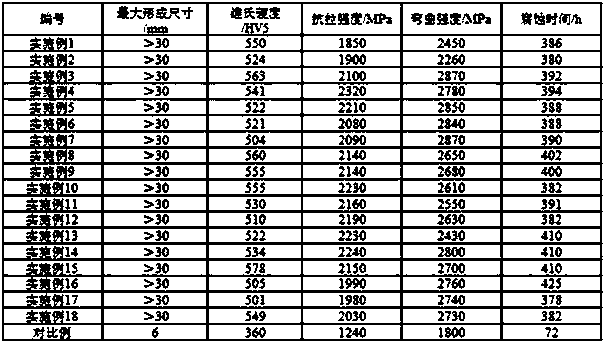

Examples

Embodiment 1

[0029] The composition of zirconium-based amorphous alloy conforms to the chemical formula Zr 78 Cu 3.4 Ni 10 Nb 4.5 al 3.6 Y 0.5 , its preparation method is:

[0030] S01, according to the chemical formula of the zirconium-based amorphous alloy, the metal raw material with a purity higher than 99.9% is weighed and mixed, wherein Nb is added as a raw material in the form of a NbAl master alloy, and the atomic molar ratio of Nb to Al in the NbAl master alloy is 3: 2. Then smelt in a vacuum induction furnace to form a molten soup. The melting process of alloy raw materials includes a high-power rapid melting stage and a medium-power refining stage. In the high-power rapid melting stage, the heating power is 5000W and the time is 5s, and the medium-power refining stage The heating power is 2500W and the time is 15s. The melting temperature is in the range of 1000-1020°C, and the vacuum degree of the melting environment is 10 -2 Pa;

[0031]S02, the smelting is completed a...

Embodiment 2

[0034] The composition of zirconium-based amorphous alloy conforms to the chemical formula Zr 73 Cu 8 Ni 10 Nb 4.9 Al 3.6 Y 0.5 , its preparation method is:

[0035] S01, according to the chemical formula of the zirconium-based amorphous alloy, the metal raw materials with a purity higher than 99.9% are weighed and mixed, wherein Nb is added as a raw material in the form of a NbAl master alloy, and the atomic molar ratio of Nb and Al in the NbAl master alloy is 2.8: 2. Then smelt in a vacuum induction furnace to form a molten soup. The melting process of the alloy raw materials includes a high-power rapid melting stage and a medium-power refining stage. The heating power of the high-power rapid melting stage is 4500W and the time is 8s, and the medium-power refining stage The heating power is 1800W and the time is 15s. The melting temperature is in the range of 1000-1050°C, and the vacuum degree of the melting environment is 10 -2 Pa;

[0036] S02, the smelting is comp...

Embodiment 3

[0039] The composition of zirconium-based amorphous alloy conforms to the chemical formula Zr 73 Cu 8 Ni 10 Nb 4.9 Al 3.6 Y 0.5 , its preparation method is:

[0040] S01, according to the chemical formula of the zirconium-based amorphous alloy, the metal raw materials with a purity higher than 99.9% are weighed and mixed, wherein Nb is added as a raw material in the form of a NbAl master alloy, and the atomic molar ratio of Nb and Al in the NbAl master alloy is 2.8: 2. Then smelt in a vacuum induction furnace to form a molten soup. The melting process of the alloy raw materials includes a high-power rapid melting stage and a medium-power refining stage. The heating power of the high-power rapid melting stage is 4500W and the time is 8s, and the medium-power refining stage The heating power is 1800W and the time is 15s. The melting temperature is in the range of 1000-1050°C, and the vacuum degree of the melting environment is 10 -2 Pa;

[0041] S02, the smelting is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com