Pulping device, pulping system, pulp production equipment formed by pulping system and application of pulping device or pulping system or pulp production equipment

A technology for pulping and equipment, which is used in pulp beating methods, pulping with inorganic alkalis, pulp beating/refining methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1 A kind of pulping device

[0082] A pulping device is composed of a transmission device and a pulp refining equipment, and the transmission device and the pulp refining equipment are all in the same closed system.

Embodiment 2

[0083] Embodiment 2 A pulping device

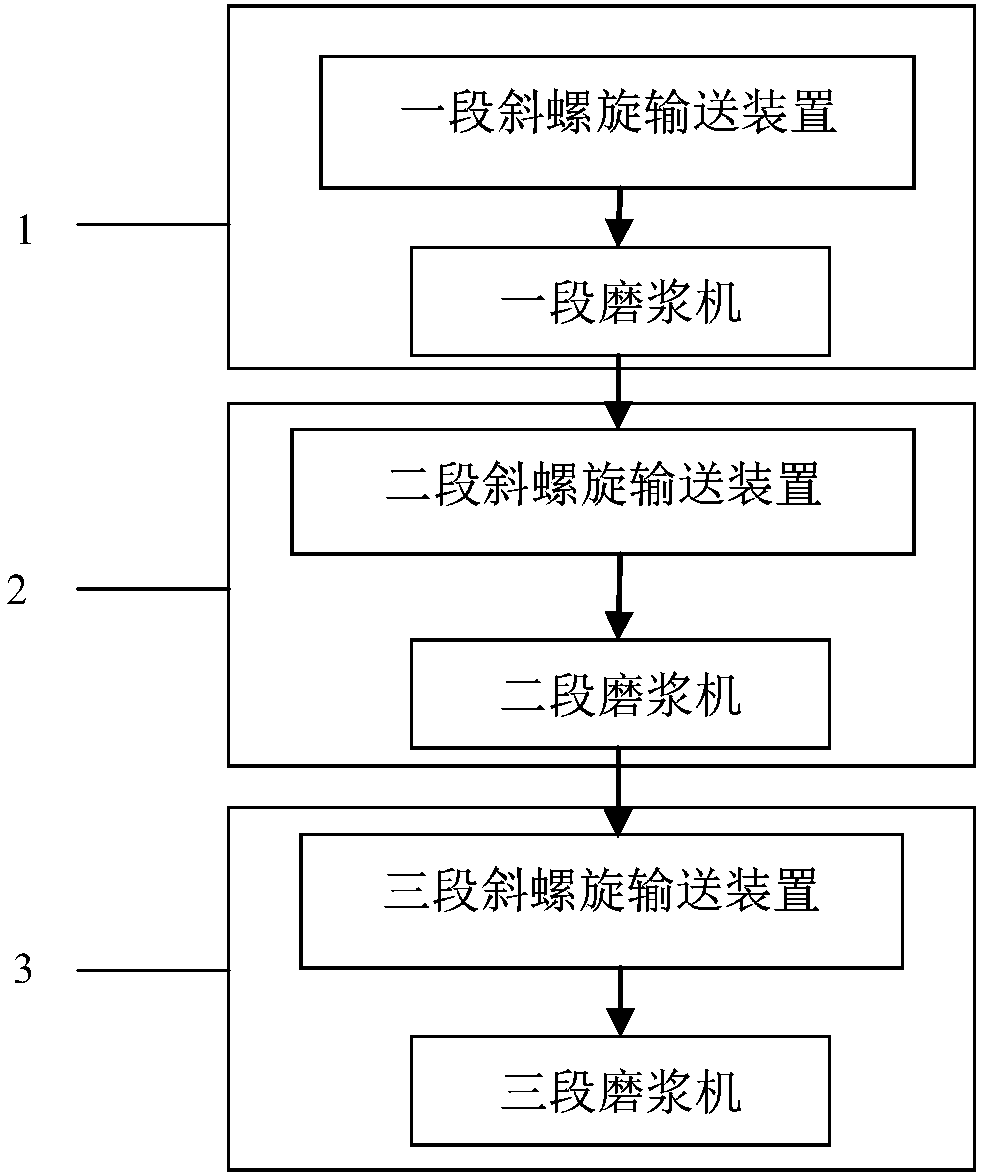

[0084] like figure 1 A pulping plant shown is composed of three continuous operating units in the same closed system, each operating unit is composed of a transmission device and a refining equipment. That is to say, the pulping device is composed of a first pulping unit, a second pulping unit and a third pulping unit, wherein the first pulping unit is composed of a helical screw conveying device and a refiner, and the second pulping unit consists of two The three-stage inclined screw conveying device and the second-stage refiner are composed of the three-stage pulping unit. in a closed system.

Embodiment 3

[0085] Embodiment 3 A kind of pulping process

[0086] The pulping device described in Example 2 was used for pulping.

[0087] One-stage pulping: place the raw material after fiber brooming in a first-stage inclined screw conveying device, add additives to the raw material, and add a dryness regulator at the same time, so that the dryness of the raw material reaches 50-70%, and the temperature in the transmission stage is 50 -90°C, transport the slurry to the first-stage refiner; the first-stage refiner kneads the slurry, and the refining temperature is 70-110°C to obtain a first-stage pulping slurry with a beating degree of 35-45°SR. Fiber wet weight 3-11g;

[0088] The mass ratio of the added amount of the auxiliary agent to the added amount of the dryness regulator is 1:1.5-2;

[0089]Two-stage pulping: the first-stage pulping slurry enters the second-stage oblique screw conveying device, and the dryness regulator is added to make the raw material dryness reach 30-50%, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com