Porous three-element compound positive plate as well as preparation method and application thereof

A ternary composite and positive electrode technology, applied in electrode manufacturing, electrical components, battery electrodes, etc., can solve problems such as low cycle life of solid-state batteries, poor electrode/electrolyte interface compatibility, and interface impedance affecting ion transmission. Achieve the effect of enhancing the ability of ion transport, improving electrochemical performance, and improving interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

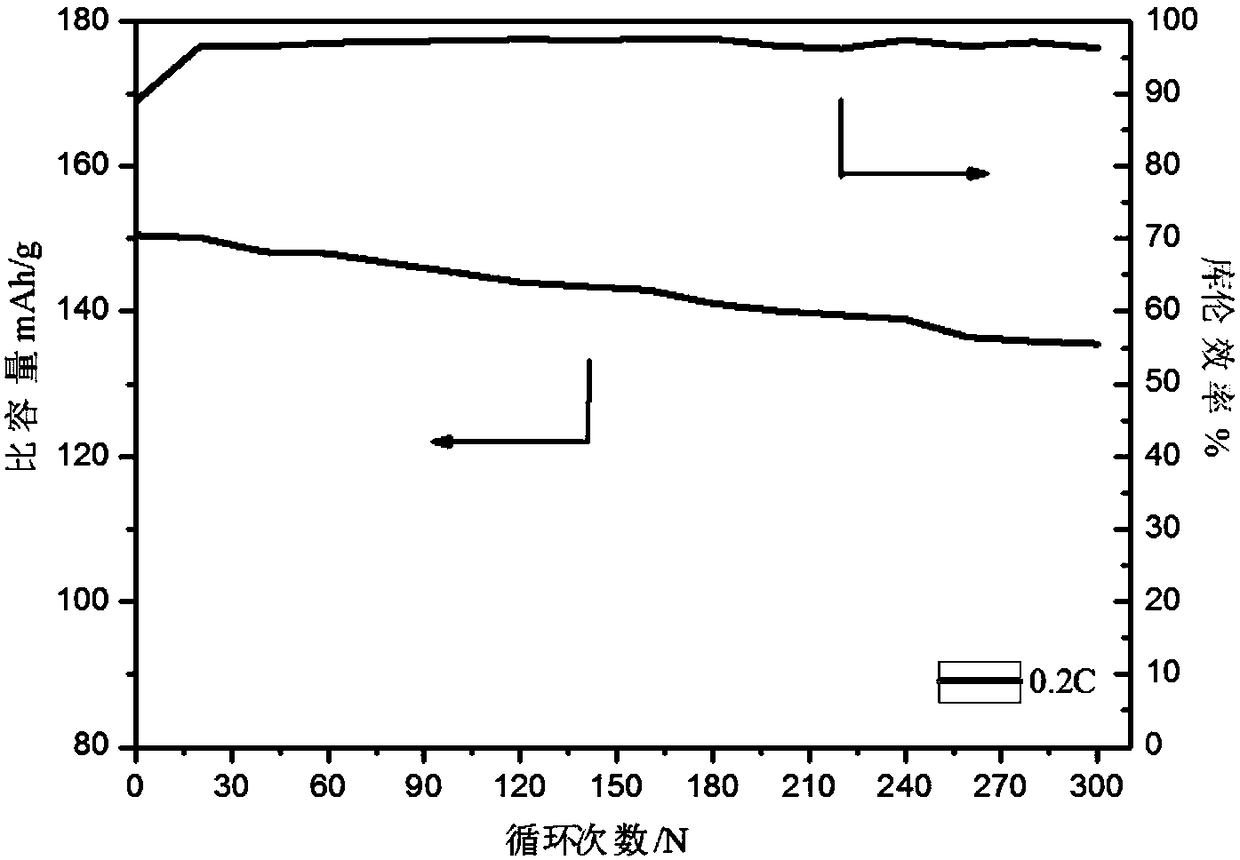

Examples

Embodiment 1

[0024] A porous ternary composite positive electrode, characterized in that: the porous ternary positive electrode comprises the following materials: ternary 532, Surpe-P, polyvinylidene fluoride, lithium lanthanum zirconium tantalum oxide, LiTFSI and acetone, the mass parts of each material They are: ternary 532: 80 parts, Surpe-P: 5 parts, polyvinylidene fluoride: 5 parts, lithium lanthanum zirconium tantalum oxide: 15 parts, LiTFSI: 10 parts, acetone: 5 parts.

[0025] A preparation method for a porous ternary composite positive electrode sheet, comprising the following steps: Step 1: Mix ternary 532, Surpe-P, polyvinylidene fluoride, lithium lanthanum zirconium tantalum oxide and LiTFSI uniformly and then disperse them in N-methylpyrrolidone in solution;

[0026] Step 2: fully stir with a vacuum planetary mixer to obtain a positive electrode slurry;

[0027] Step 3: Then add uniformly dispersed acetone, and fully stir with a vacuum planetary mixer to obtain a composite po...

Embodiment 2

[0033] A porous ternary composite positive electrode is characterized in that: the porous ternary positive electrode comprises the following materials: ternary 532, acetylene black, polyvinylidene fluoride, lithium lanthanum titanium oxide, LiClO 4 and polyvinylpyrrolidone, the mass parts of each material are: ternary 532:85 parts, acetylene black: 2 parts, polyvinylidene fluoride: 3 parts, lithium lanthanum titanium oxide: 7 parts, LiClO 4 : 4 parts, polyvinylpyrrolidone: 4 parts.

[0034] A preparation method of a porous ternary composite positive electrode sheet, comprising the following steps: Step 1: combine ternary 532, acetylene black, polyvinylidene fluoride, lithium lanthanum titanium oxide and LiClO 4 After mixing evenly, disperse in N-methylpyrrolidone solution;

[0035] Step 2: fully stir with a vacuum planetary mixer to obtain a positive electrode slurry;

[0036] Step 3: then add uniformly dispersed polyvinylpyrrolidone, and fully stir with a vacuum planetary m...

Embodiment 3

[0042] A porous ternary composite positive electrode, characterized in that: the porous ternary positive electrode comprises the following materials: ternary 532, graphene, polyvinylidene fluoride, lithium lanthanum zirconium oxygen, LiPF 6 And ammonia carbonate, the mass parts of each material are: ternary 532:90 parts, graphene: 1 part, polyvinylidene fluoride: 2 parts, lithium lanthanum zirconium oxygen: 2 parts, LiPF 6 : 3 parts, ammonia carbonate: 2 parts.

[0043] A preparation method of a porous ternary composite positive electrode sheet, comprising the following steps: step 1: combining ternary 532, graphene, polyvinylidene fluoride, lithium lanthanum zirconium oxygen, LiPF 6 After mixing evenly, disperse in N-methylpyrrolidone solution;

[0044] Step 2: fully stir with a vacuum planetary mixer to obtain a positive electrode slurry;

[0045] Step 3: then add uniformly dispersed ammonia carbonate, and fully stir with a vacuum planetary mixer to obtain a composite positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com