Device and method of utilizing catalytic distillation coupling technology to produce high-purity methylal

A catalytic distillation and catalytic distillation tower technology, applied in the field of high-purity methylal production using catalytic distillation coupling technology, can solve the problems of low production efficiency, long process, low purity, etc., and achieve environmentally friendly production conditions, mild process conditions, and process short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

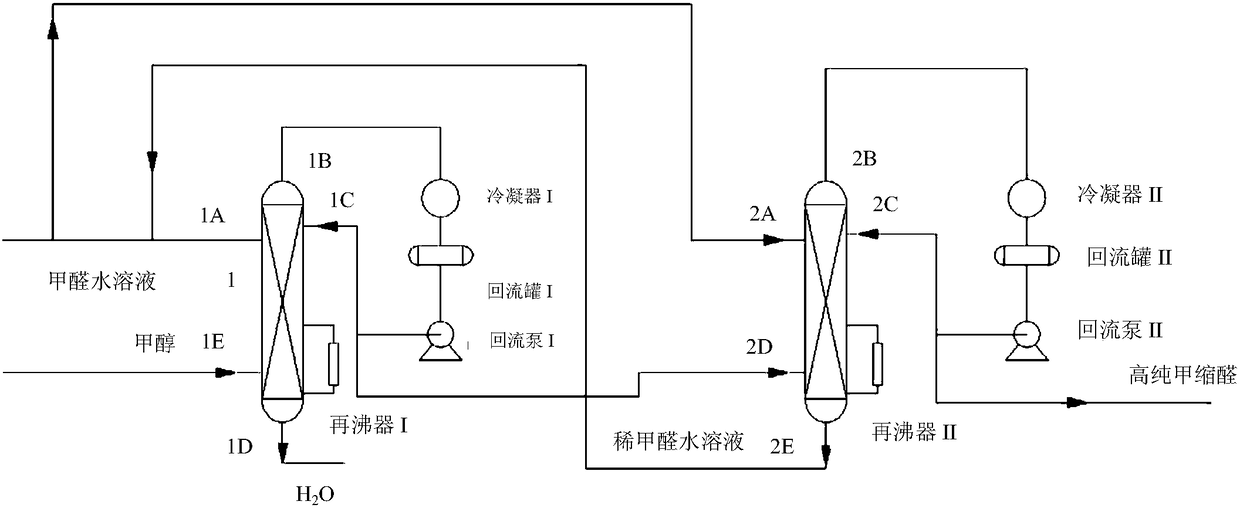

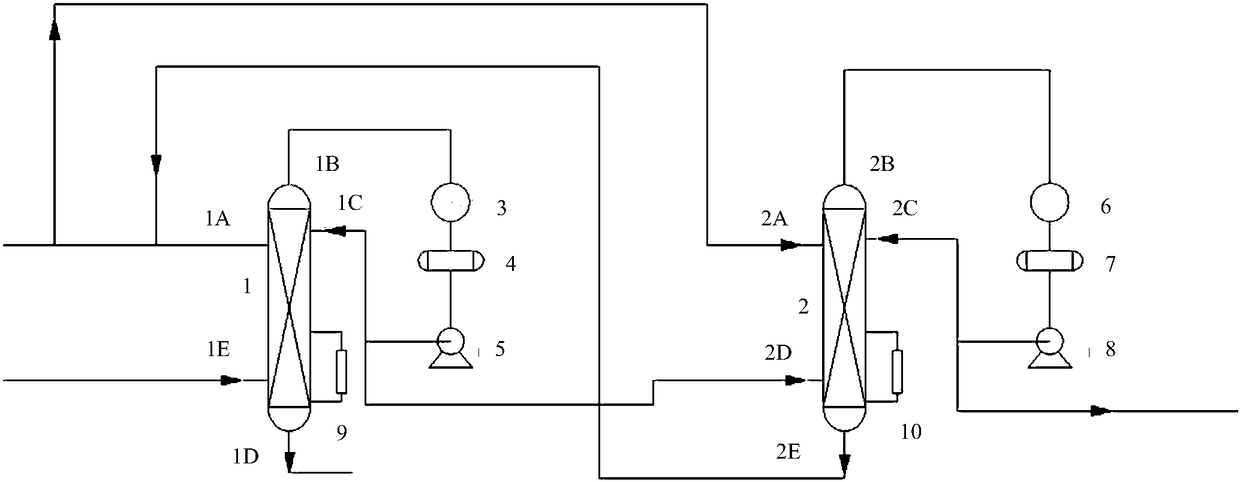

[0060] A kind of method utilizing catalytic distillation coupling technology to produce high-purity methylal, comprises the following steps:

[0061] (1) formaldehyde aqueous solution, methyl alcohol enter in catalytic distillation tower 1 respectively from formaldehyde import 1, methanol import, under the catalysis action of catalyst in it, react; The tower bottom of catalytic distillation tower 1 obtains water, and is discharged by water outlet, The top of the catalytic distillation tower I obtains the azeotrope, and is discharged from the azeotrope outlet, and the azeotrope is methylal containing methanol; the azeotrope flows through the condenser I, the reflux tank I, and the reflux pump I successively, A part is refluxed by the azeotrope reflux port to the catalytic distillation tower I for reflux, and the other part enters the catalytic distillation tower II by the azeotrope inlet;

[0062] In the described formaldehyde aqueous solution, the mass fraction of formaldehyde...

Embodiment 2

[0077] A method for producing high-purity methylal using catalytic distillation coupling technology, other process conditions and methods are the same as in Example 1, the difference is: ① The stripping section of catalytic distillation tower I and catalytic distillation tower II is designed as a sieve plate, and the sieve plate It is a high-efficiency floating valve sieve plate, the number of layers of the sieve plate is N=10, and the distance between the layers is 450mm; ②The catalysts in the catalytic section of the catalytic distillation tower I are the KCD006 resin catalysts produced by our company. The catalyst filled in the catalytic section of the distillation tower II is the D006 resin catalyst produced by our company; the yield of methylal is 99.6%, and the purity is 99.6%.

Embodiment 3

[0079]A kind of method that utilizes catalytic distillation coupling technology to produce high-purity methylal, other process conditions and method are the same as embodiment 1, difference is: 1. the catalyst that the catalytic sections of catalytic distillation tower I and catalytic distillation tower II are all packed is all this The D008 resin catalyst produced by the company; ②The catalysts are packed in bulk; the yield of methylal is 99.4%, and the purity is 99.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com