Epoxy resin conductive adhesive, electromagnetic shielding film, and preparation method of epoxy resin conductive adhesive and electromagnetic shielding film

An electromagnetic shielding film, epoxy resin technology, applied in the direction of conductive adhesives, adhesives, film/sheet adhesives, etc., can solve the problems of expensive, difficult to use, poor performance, etc., to achieve high conductivity, Simple process and high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

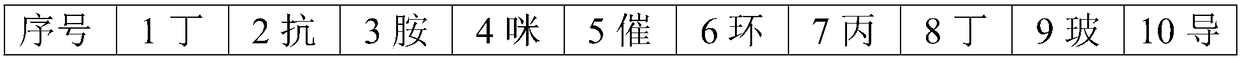

[0027] Table 1: The chemical composition of the electromagnetic shielding film epoxy resin conductive adhesive of the first embodiment

[0028]

[0029]

[0030] Based on the materials in Table 1, the preparation method of the epoxy resin conductive adhesive of the first electromagnetic shielding film is as follows:

[0031] Step 1, preparation of rubber solution: Cut 13 parts of soft nitrile rubber into 1 cm cubes, fully mix with 10 parts of methyl ethyl ketone, put it into the reaction ax and continue to stir for 24 hours, and stir at a constant temperature at a constant speed, and wait for 24 hours to completely dissolve After that, stand still to obtain a rubber solution.

[0032] Step 2, preparation of epoxy resin solution: crush 14 parts of glycidyl ester epoxy resin solid shape into small pieces, fully mix with 10 parts of methyl ethyl ketone, put it into the first dispersion bucket and keep stirring for 6 hours, and keep the temperature constant Stir at a consta...

Embodiment 2

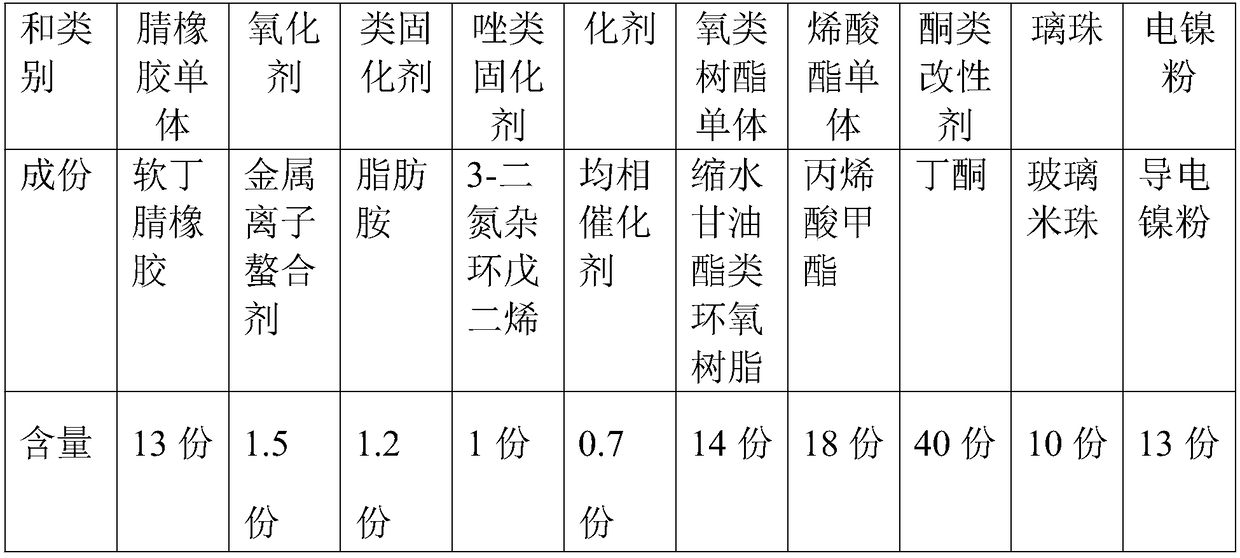

[0037] Table 2: The chemical composition of the electromagnetic shielding film epoxy resin conductive glue of the 2nd embodiment

[0038]

[0039] Based on the materials in Table 2, the preparation method of the epoxy resin conductive adhesive of the second electromagnetic shielding film is as follows:

[0040] Step 1, preparation of rubber solution: Cut 15 parts of hard nitrile rubber into 1 cm cubes, fully mix them with 10 parts of MEK and put them into the reaction axe for 24 hours, keep stirring at a constant temperature and at a constant speed, and wait for 24 hours to completely dissolve , static rubber solution is obtained.

[0041] Step 2, preparation of epoxy resin solution: Crush 14 parts of diphenolic propane type epoxy resin into small pieces in solid shape, fully mix with 12 parts of MEK, put it into the first dispersion bucket and keep stirring for 6 hours, and keep the temperature constant Stir at a constant speed, and after 6 hours of complete dissolution, ...

Embodiment 3

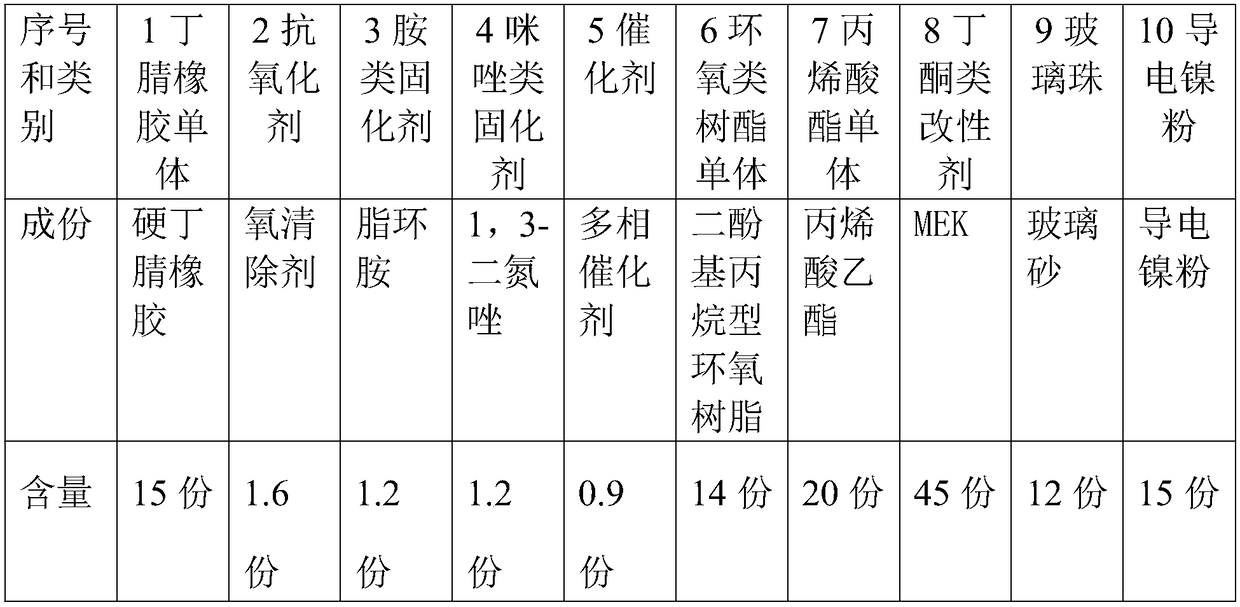

[0046] Table 3: The chemical composition of the electromagnetic shielding film epoxy resin conductive glue of the 3rd embodiment

[0047]

[0048] Based on the materials in Table 3, the preparation method of the epoxy resin conductive adhesive of the third electromagnetic shielding film is as follows:

[0049] Step 1, preparation of rubber solution: Cut 14 parts of soft nitrile rubber into 1 cm cubes, fully mix with 10 parts of 2-oxobutane, put them into the reaction ax and continue to stir for 24 hours, and stir at a constant temperature and at a constant speed. After 24 hours of complete dissolution, stand still to obtain a rubber solution.

[0050] Step 2, preparation of epoxy resin solution: 14 parts of glycidyl ester epoxy resin solid shape is crushed into small pieces, fully mixed with 11 parts of 2-oxobutane and put into the first dispersion bucket for continuous stirring for 6 hours, and stirred at a constant temperature and at a constant speed. After 6 hours of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com