Purification method of rhTNK-tPA (recombinant human TNK tissue-type plasminogen activator for injection) cell harvesting fluid

A purification method and cell technology, applied in the field of protein purification, can solve the problems of easy agglomeration of the filler, low recovery rate, shortened service life of the filler, etc., and achieve the effects of reducing production cost, simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

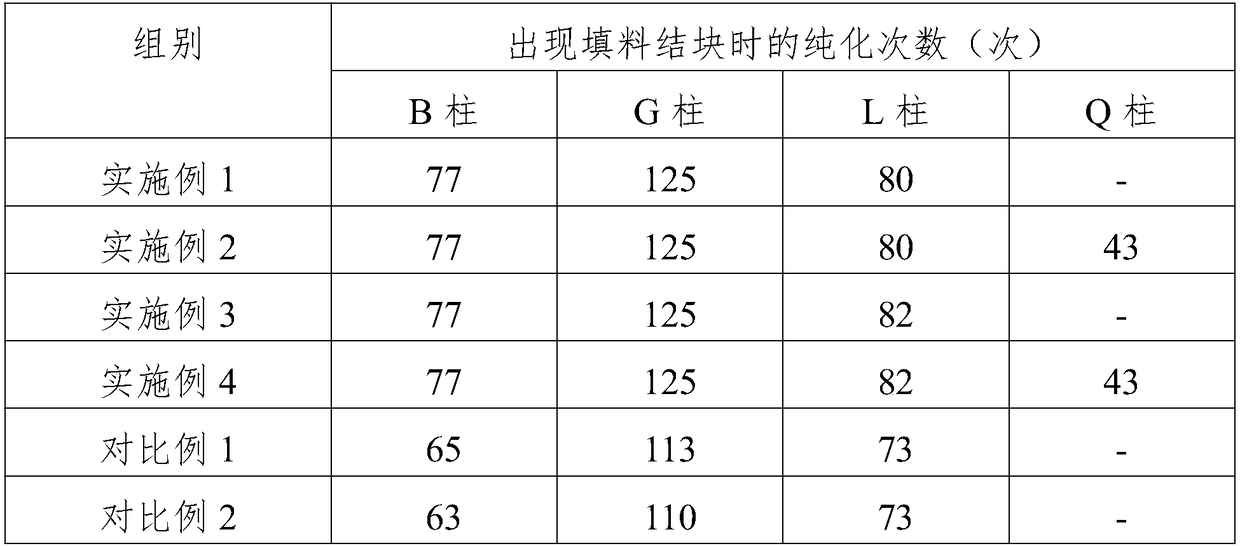

Examples

Embodiment 1

[0027] Embodiment 1, rhTNK-tPA purification

[0028] A) Filtration of the supernatant: harvest the cell supernatant in the cell reactor, and filter it with a 0.2 μm sterile filter after deep filtration;

[0029] B) Blue Sepharose 6FastFlow affinity column chromatography: Before the chromatography, the column is equilibrated with 2.5 times the column volume buffer ①, and its components are 20mM phosphate buffer and 0.04% Tween 80, pH7.2; for sample loading, use 2.5 times the column volume of buffer ② to wash out impurity proteins, the components are: 20mM phosphate buffer, 2M sodium chloride and 0.04% Tween 80, pH7.2; use 3 times The target protein was obtained by eluting with the column volume of eluent I. The components of eluent I were 20mM phosphate buffer, 1M sodium chloride, 2M urea and 0.04% Tween 80, and the pH value of the eluent was 7.0;

[0030] C) Lysine HyperD affinity column chromatography: The equilibration and sample loading process is the same as step B). Afte...

Embodiment 2

[0033] Embodiment 2, rhTNK-tPA purification

[0034] The difference between Example 2 and Example 1 is that the Capto Q anion exchange resin column chromatography step is added after step C), and the specific operation is: equilibrate and load according to step C), and use 2.0 times the column volume of the eluent IV was eluted to obtain the target protein. The composition of eluent IV was: 20mM phosphate buffer, 0.1M 6-amino-n-caproic acid, 0.2M arginine, 0.04% Tween 80, and the pH value of the eluent was 7.0. The dosage is 2.0 times the volume, and the remaining parameters and operations are as shown in Example 1.

[0035] After testing, the obtained rhTNK-tPA solution had a purity of 99.8%, a recovery rate of 88.3%, and a specific activity of 526,000 IU / mg.

Embodiment 3

[0036] Embodiment 3, rhTNK-tPA purification

[0037] The difference between embodiment 3 and embodiment 1 is that the order of step C) and step D) is reversed, and other parameters and operations are as shown in embodiment 1.

[0038] After testing, the obtained rhTNK-tPA solution had a purity of 99.3%, a recovery rate of 96.5%, and a specific activity of 625,000 IU / mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific activity | aaaaa | aaaaa |

| Specific activity | aaaaa | aaaaa |

| Specific activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com