Textile fabric dyeing and drying integrated machine

A technology of textile fabrics and integrated machine, which is applied in the processing of textile materials, accessories of textile processing machines, and equipment configuration for processing textile materials, etc. Improve efficiency and effect, improve dyeing effect, efficient and fast dyeing and drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

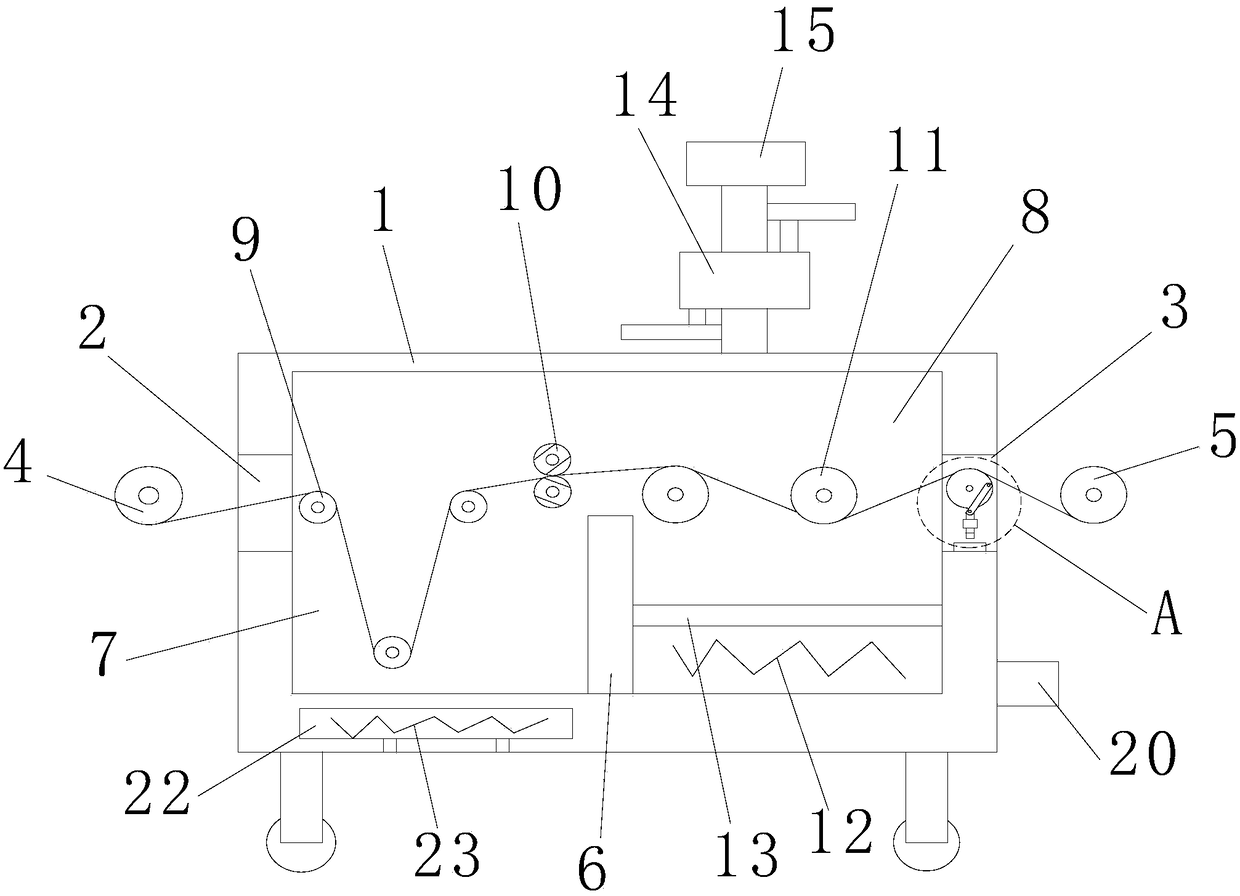

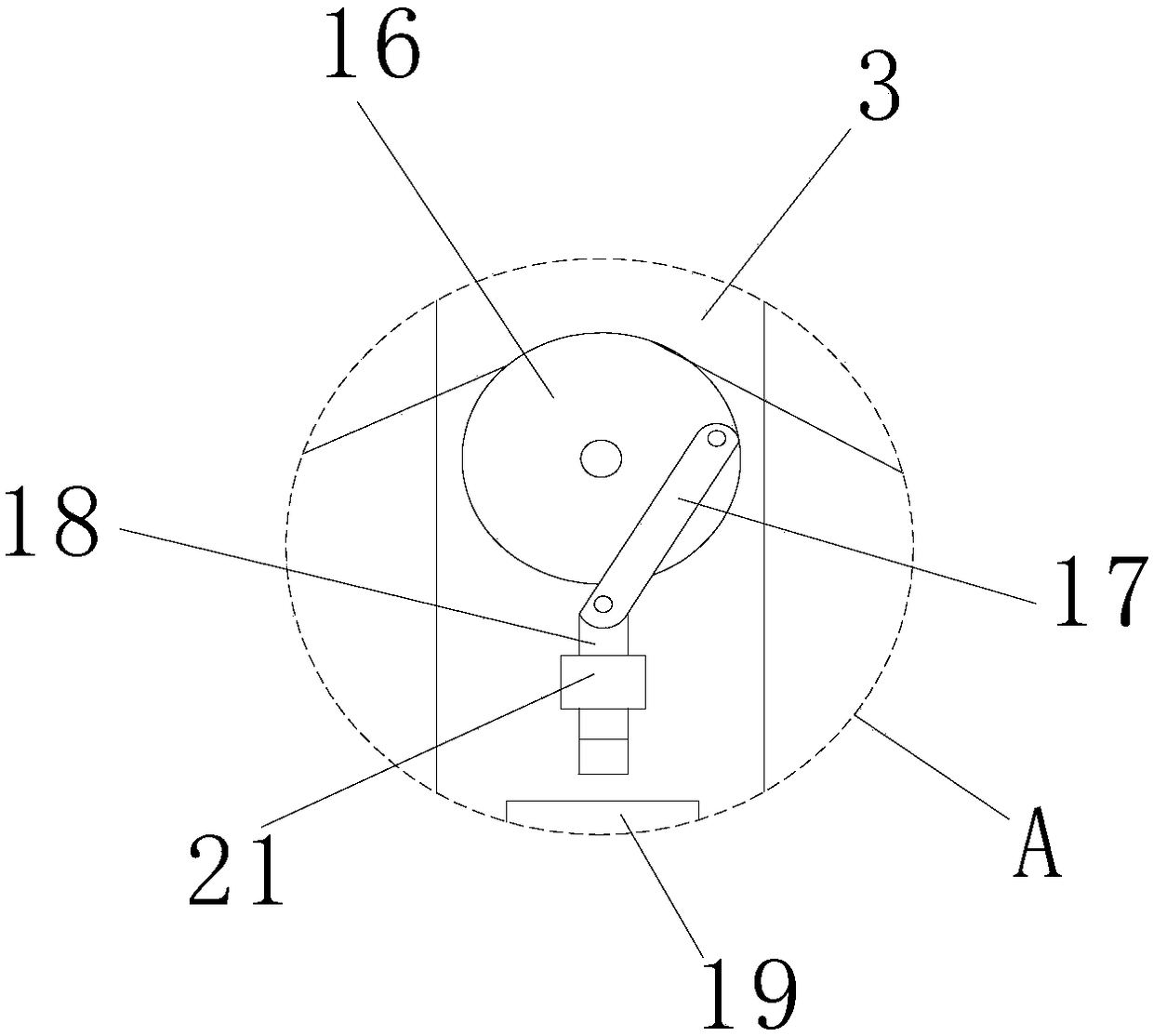

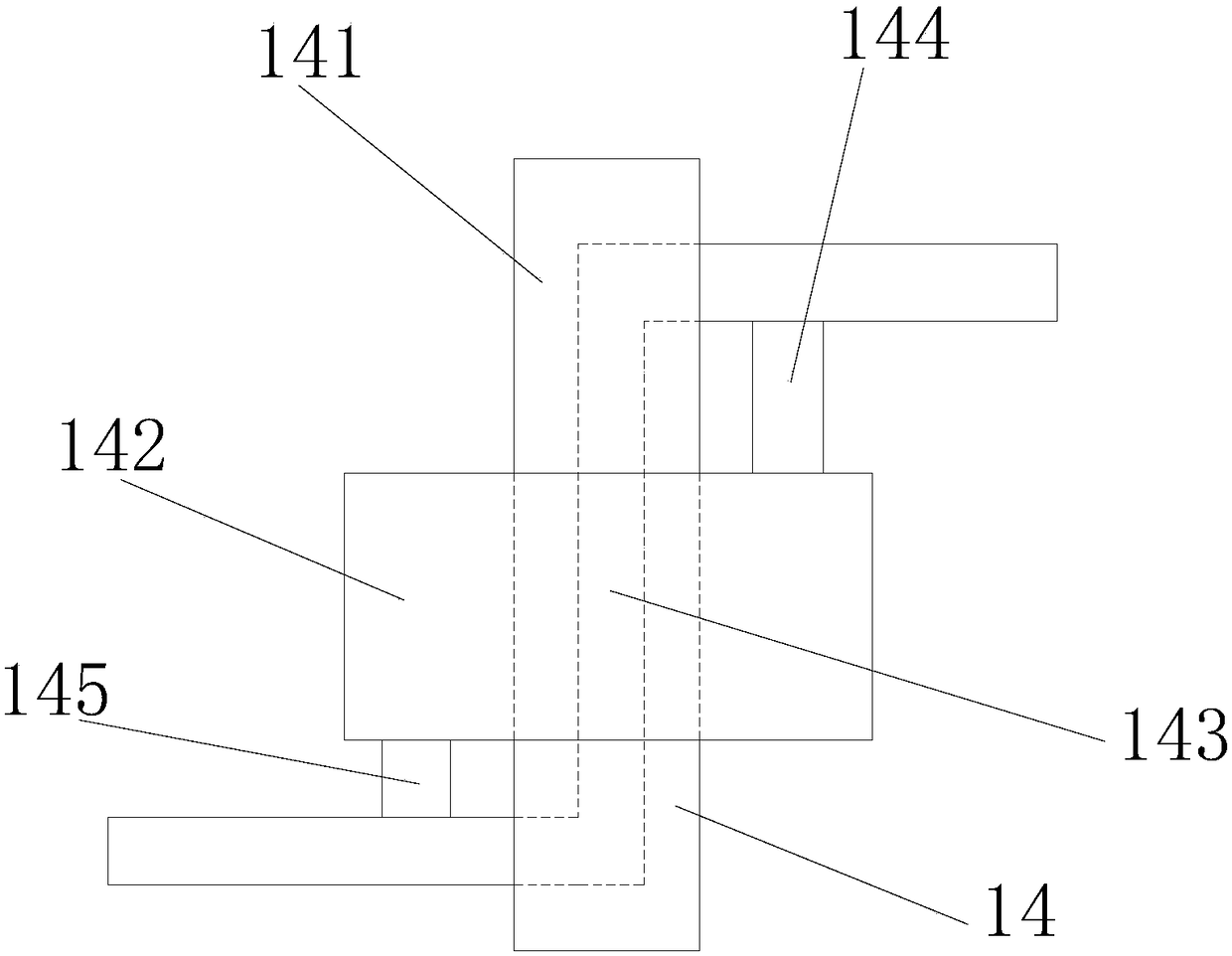

[0018] refer to figure 1 , 2 , 3, an integrated machine for dyeing and drying textile fabrics of the present invention, comprising a chassis 1, a material inlet 2, a material outlet 3, a cloth releasing roller 4, a cloth receiving roller 5, a partition 6, a dye box 7, and a drying box 8. Dyeing roller 9, squeezing roller 10, drying roller 11, first heating wire 12, isolation net 13, exhaust pipe 14, exhaust fan 15, fabric guide roller 16, transmission rod 17, pressure rod 18, pressure sensor 19. Counter 20, sleeve 21, installation cavity 22 and second heating wire 23, the left side of the cabinet 1 is provided with a material inlet 2, and the right side of the cabinet 1 is provided with a discharge port 3, so The left side of the feed port 2 is provided with a cloth releasing roller 4, the right side of the discharge port 3 is provided with a cloth receiving roller 5, and the cabinet 1 is fixedly provided with a dividing plate 6, and the dividing plate 6 divides the cabinet. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com