Device for recovering smoke waste heat and dedusting and eliminating colored smoke plume

A flue gas waste heat and dust removal device technology, which is applied in the field of environmental protection, can solve the problems of colored plume that only invests but has no profit, cannot make deep use of a large amount of latent heat, waste energy and water resources, etc., to achieve the elimination of colored plume, lower temperature, reduce The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

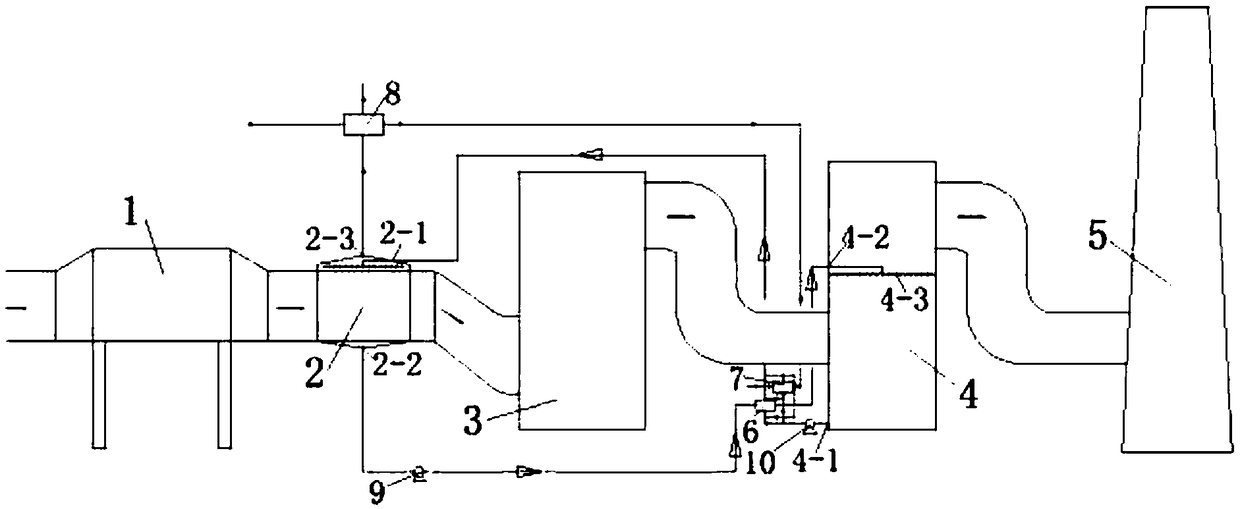

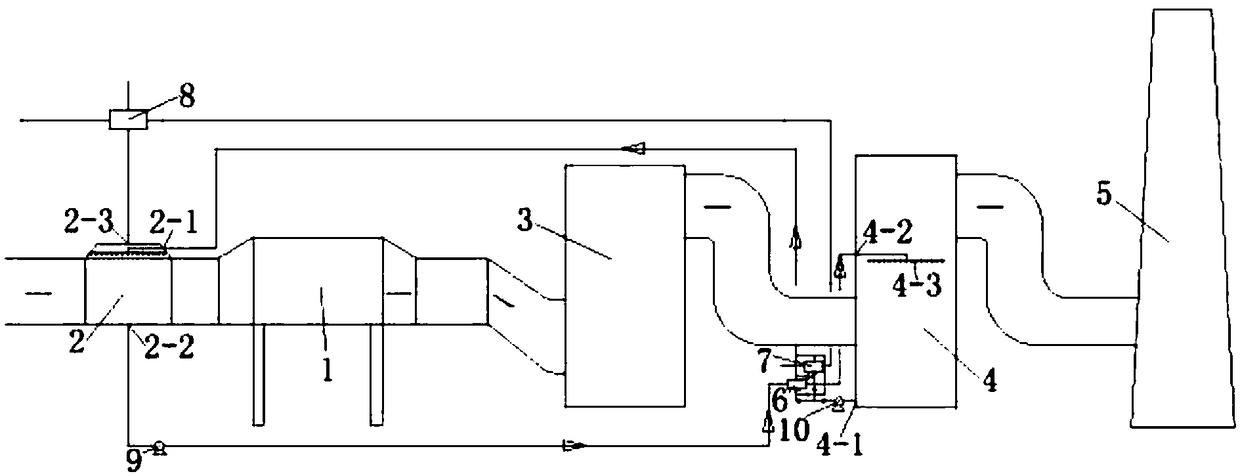

[0044] This embodiment provides a device for recovering waste heat of flue gas and cooperating with dust removal to eliminate colored plumes, such as figure 1 As shown, it includes a dust removal device 1, a desulfurization device 3 and an absorption device 4 connected in sequence. For example, the dust removal device 1 can be an electric precipitator, and the desulfurization device 3 can be a desulfurization tower. It also includes a regeneration device 2, which is arranged between the dust removal device 1 and the Between the desulfurization devices 3; in the present embodiment, the absorption device 4 includes a second housing and a spraying device 4-3, and the spraying device 4-3 is arranged in it near the middle and upper part of the second housing, and spraying One end of the device 4-3 communicates with the outlet of the absorption liquid, and a second nozzle is arranged at the opposite end to spray the absorption liquid (i.e. thick absorption liquid) to the middle and l...

Embodiment 2

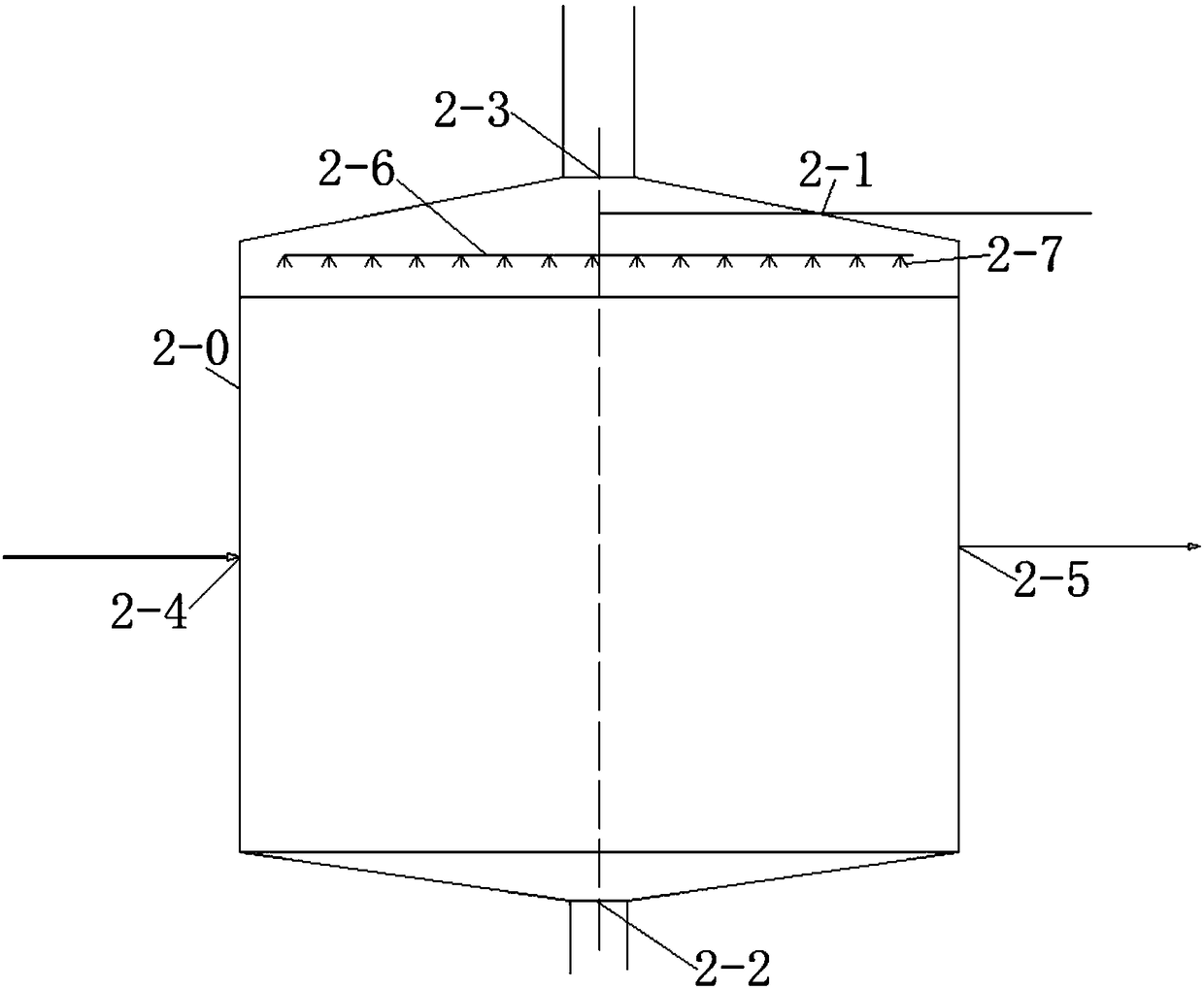

[0052] This embodiment provides a device for recovering waste heat of flue gas and synergistically removing dust to eliminate colored plume. Regeneration also includes a liquid distributor, including several guide tubes 2-6 and several first nozzles 2-7 arranged at intervals along the length direction of the guide tubes 2-6, and the guide tubes 2-6 are located in the waste liquid In the first shell 2-0 between the heat exchange channel 2-11 and the top end of the first shell 2-0, the first nozzle 2-7 faces the waste liquid heat exchange channel 2-11 to spray waste liquid into it, The waste liquid then flows into the waste liquid heat exchange channel 2-11, forming a liquid film with a certain thickness on the vertical wall and exchanging heat with the flue gas partition wall; specifically, as Figure 6 As shown, the guide pipe 2-6 is composed of a main guide pipe 2-6-1 and several branch guide pipes 2-6-2, the main guide pipe 2-6-1 communicates with the waste liquid inlet 2-1,...

Embodiment 3

[0054] This embodiment provides a device for recovering flue gas waste heat and cooperating with dust removal to eliminate colored plumes. On the basis of the above-mentioned embodiment 1 or 2, in order to facilitate the rapid collection of steam and absorption liquid, as shown in 3 and 4, the first shell The top of the body 2-0 is a conical top 2-8. Along the direction from the bottom to the top of the first shell 2-0, the inner diameter of the conical top 2-8 becomes smaller gradually, and the steam outlet 2-3 is arranged at The conical top of the conical top 2-8; the bottom of the first shell 2-0 is a conical bottom 2-9, along the direction from the top of the first shell 2-0 to the bottom, the conical bottom 2 The inner diameter of -9 gradually becomes smaller, and the absorption liquid outlet 2-2 is arranged at the conical bottom of the conical bottom end 2-9;

[0055] In order to make the waste liquid form a liquid film on the inner wall of the waste liquid heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com