NH3 gas sensor based on PANI@Au-In2O3 sensitive material as well as preparation method and application of NH3 gas sensor

A gas sensor, au-in2o3 technology, applied in the direction of material resistance, material analysis, material analysis through electromagnetic means, etc., can solve the problems of energy consumption limitation, increase of working temperature, etc., with simple method, strong reliability and good application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of In by hydrothermal method 2 O 3 Nano sensitive materials, with PANI@In 2 O 3 Nano sensitive materials make flat NH 3 Sensor, where In 2 O 3 The amount of addition is (In / Ani=2.5mol%), and the specific production process:

[0044] 1. Preparation of PET substrate: same as Comparative Example 1.

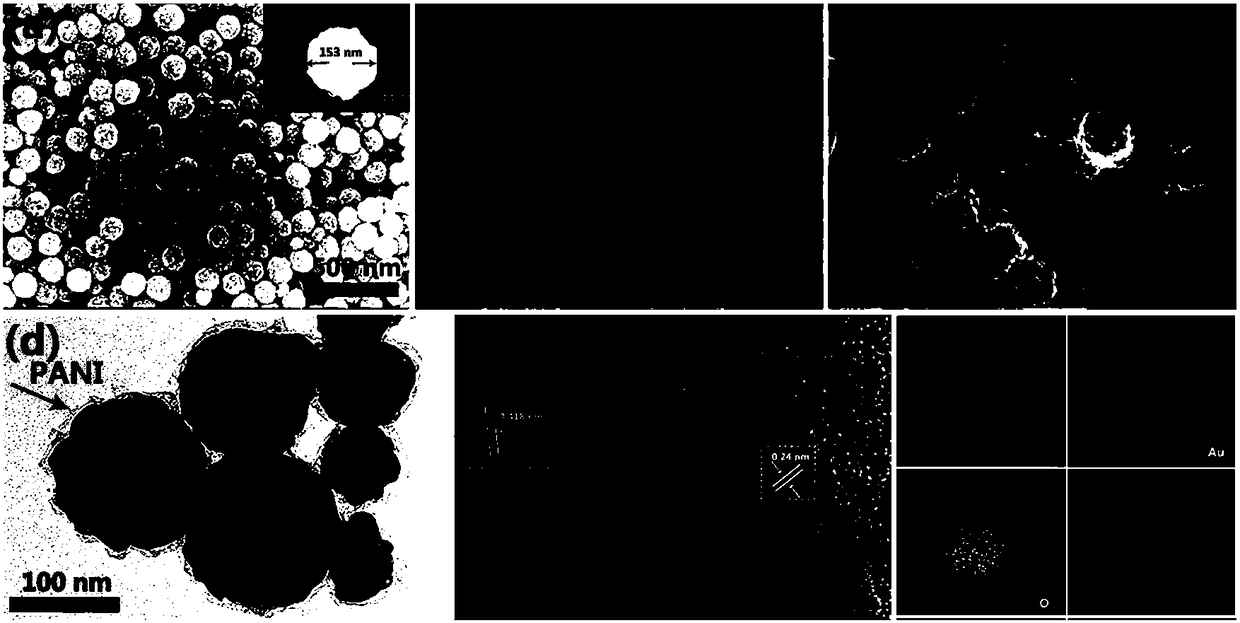

[0045] 2. Preparation of In 2 O 3 Nano sensitive material: add 1.5mmol InCl 3 ·4H 2 O was dissolved in 70mL deionized water, and 3mmol of citric acid and 20mmol of urea were added in sequence, and stirred continuously for 30min; the above solution was put into a 100mL hydrothermal kettle, and then put into a hydrothermal oven, the oven parameter was set to 130 ℃, 12h; after the reaction, the obtained product was cooled to room temperature, and then washed with water and ethanol alternately by centrifugation, and the obtained product was dried at 80°C.

[0046] After drying, the obtained product was sintered in a muffle furnace at 500°C for 3 hours at a heating rate of 2°C...

Embodiment 2

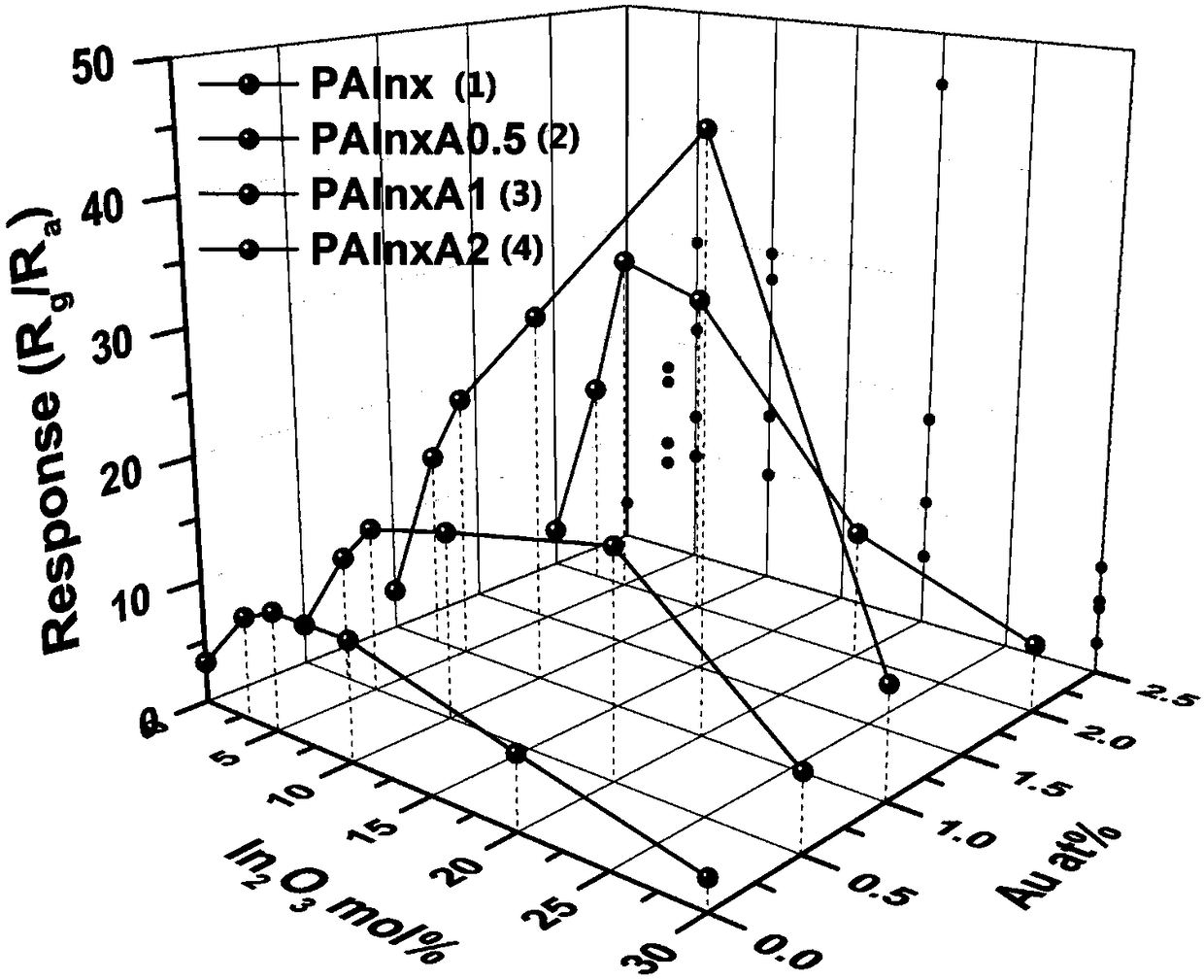

[0049] Preparation of In by hydrothermal method 2 O 3 Nano sensitive materials, with PANI@In 2 O 3 Nano sensitive materials make flat NH 3 Sensor, where In 2 O 3 The addition amount is (In / Ani=5mol%) and its specific production process:

[0050] PANI@In 2 O 3 As a nano-sensitive material (In / Ani=5mol%) to produce NH 3 Add 5mol% In during the in-situ polymerization of the sensor 2 O 3 Nanoporous material, the rest of the device manufacturing process is the same as in Example 1, and it is marked as sensor PAIn5.

Embodiment 3

[0052] Preparation of In by hydrothermal method 2 O 3 Nano sensitive materials, with PANI@In 2 O 3 Nano sensitive materials make flat NH 3 Sensor, where In 2 O 3 The addition amount of is (In / Ani=10mol%), and its specific production process:

[0053] PANI@In 2 O 3 As a nano-sensitive material (In / Ani=10mol%) to produce NH 3 Add 10mol% In during the in-situ polymerization of the sensor 2 O 3 The nanoporous material, the rest of the device manufacturing process is the same as in Example 1, and it is marked as sensor PAIn10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com