Optical film manufacturing method

A manufacturing method and technology for optical films, which are applied in chemical instruments and methods, bonding methods for surface pretreatment, optical components, etc., and can solve problems such as appearance defects and residual foreign matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

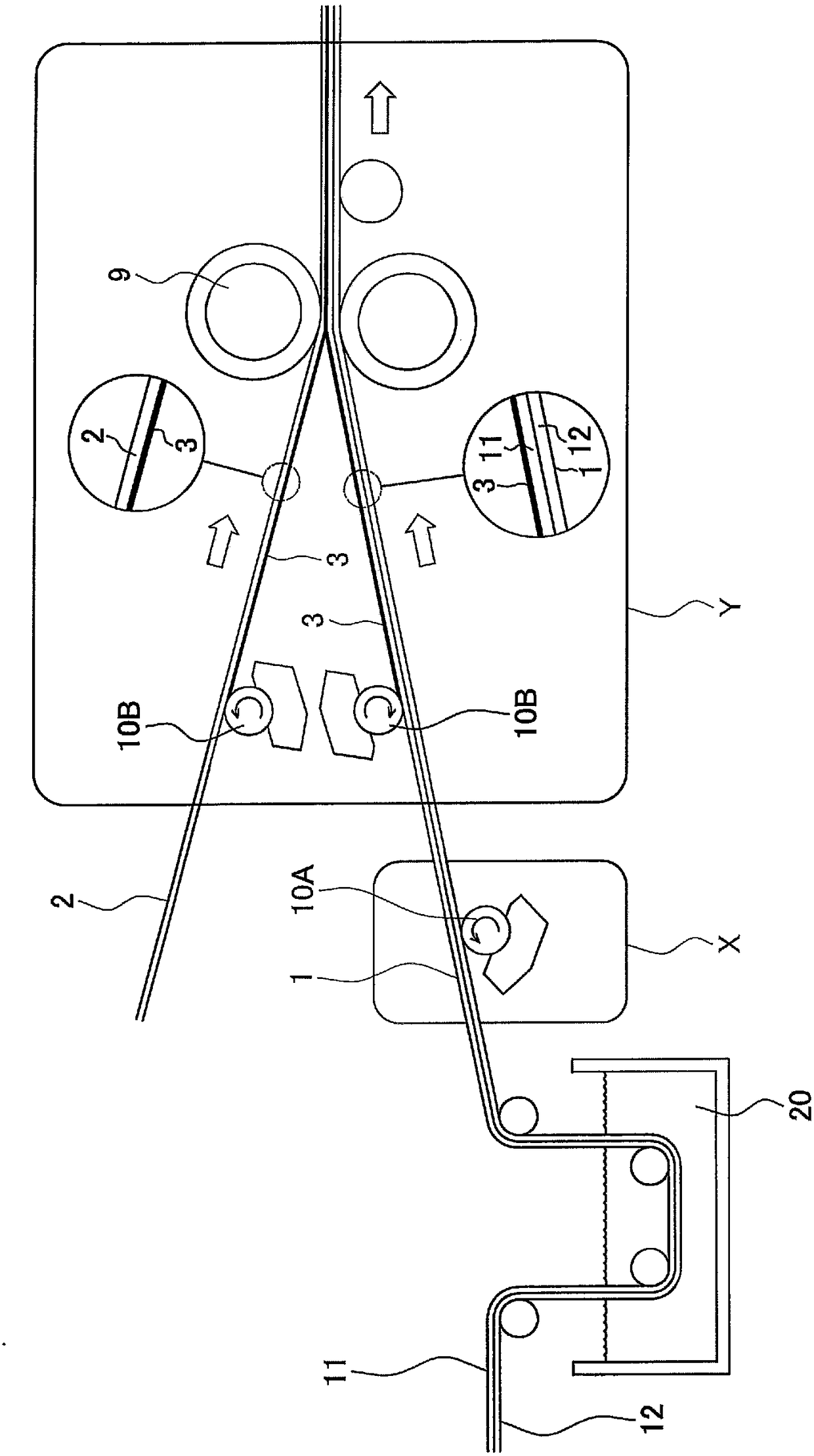

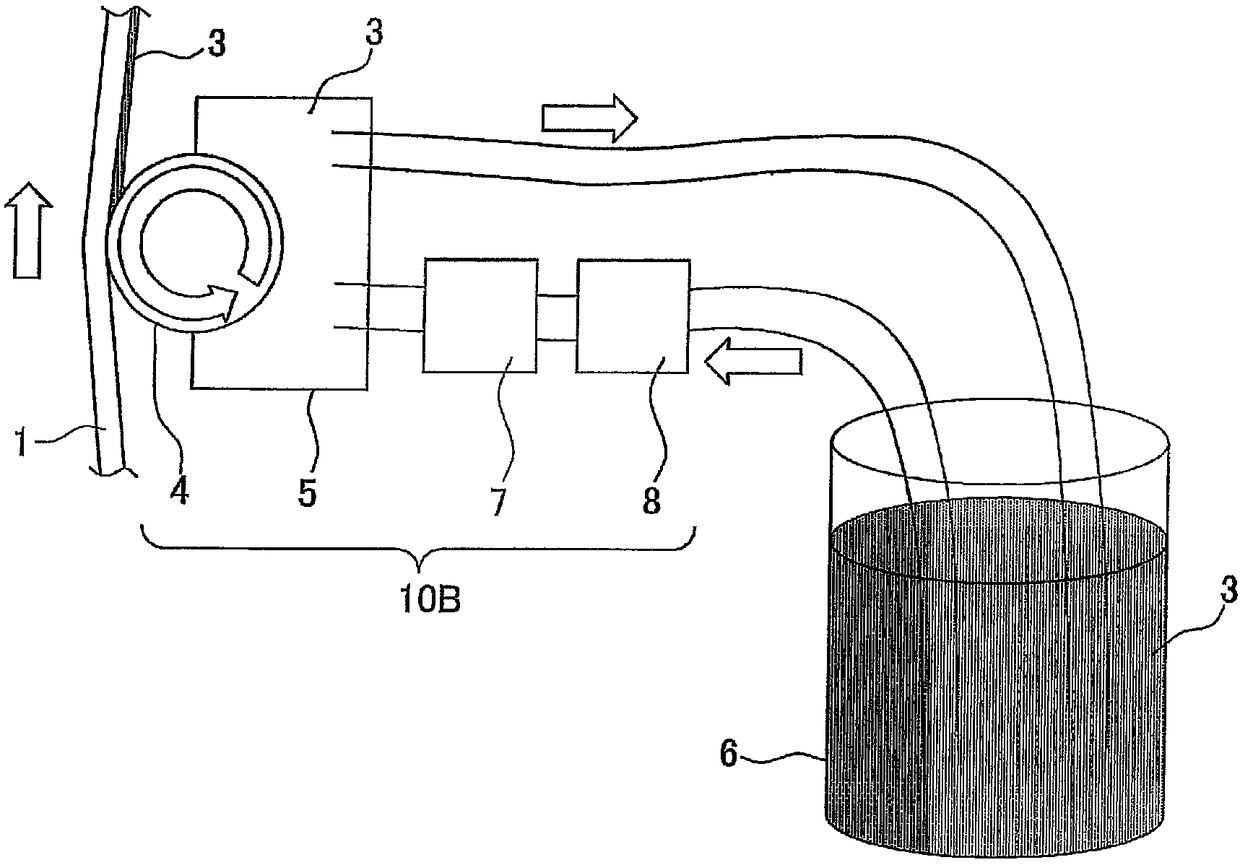

[0122] exist figure 1 , 2 In the production line shown, a gravure roll coating system 10A equipped with a gravure roll 4 (both are MCD coaters (manufactured by Fuji Machinery Co., Ltd.)) (groove shape: honeycomb grid pattern, number of groove lines of the gravure roll: 1000 bar / inch, rotation speed ratio 140%), to the side of the PET base film 12 of the first film 1 which is a laminate of the polarizing plate 11 and the PET base film 12, the liquid is applied to remove the Foreign matter and air bubbles on the side of the film 12. Then, using the gravure roll coating method 10B, the adhesive composition 3 is applied to the side of the polarizer 11 of the first film and the bonding surface of the second film, thereby removing foreign matter and air bubbles. A polarizing film was produced while air bubbles were formed. It should be noted that the adhesive composition 3 was coated on the first film and the second film so that the thickness of the adhesive layer after drying was ...

Embodiment 2~5、 comparative example 1~3

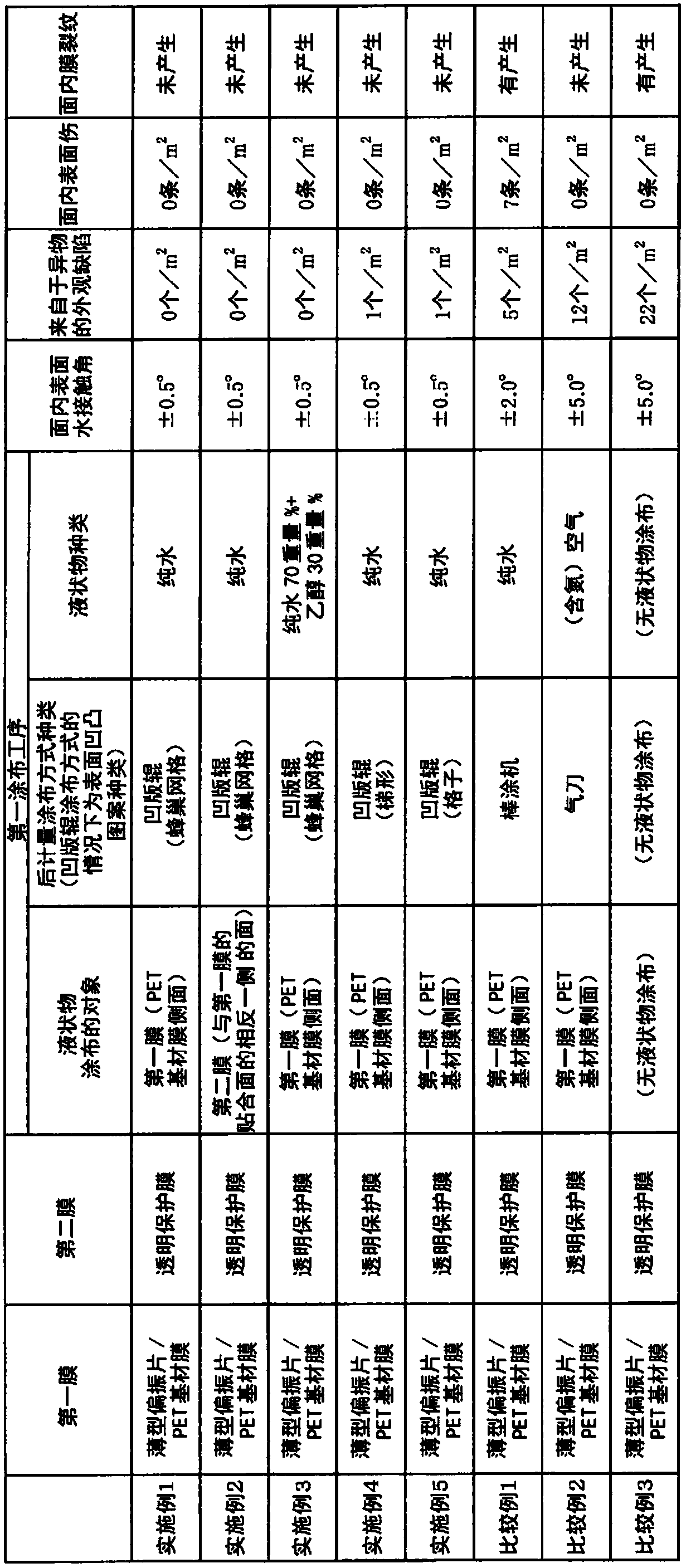

[0126] An optical film was produced in the same manner as in Example 1, except that the type of film to be subjected to the first coating step, the type of coating method, and the viscosity and composition of the liquid were changed to those described in Table 1. Commercially available coating devices were used in the bar coater coating system and the air knife coating system, respectively.

[0127]

[0128] The number of appearance defects in the adhesive layer of the polarizing film (the number of appearance defects due to foreign matter and from (bonded) air bubbles (number / m 2 )). The results are shown in Table 1.

[0129]

[0130] The in-plane surface water contact angle was measured at 10 points equally spaced in the film width direction (total width: 1500 mm) using DM-701 manufactured by Kyowa Interface Science Co., Ltd. The smaller the number of appearance defects present on the measurement surface, the smaller the variation in the water contact angle. The results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com