Preparation method of metal layer of closestool seat, closestool seat, and production method of closestool seat

A production method and metal layer technology, applied in the field of bathroom products, can solve problems such as hidden safety hazards, complicated processing technology, and slow heating speed, and achieve the effects of ensuring service life and safety, increasing specific surface area, and increasing the number of formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Specifically include the following steps:

[0059] Step 1: preparing composite resin masterbatches for nano-injection molding;

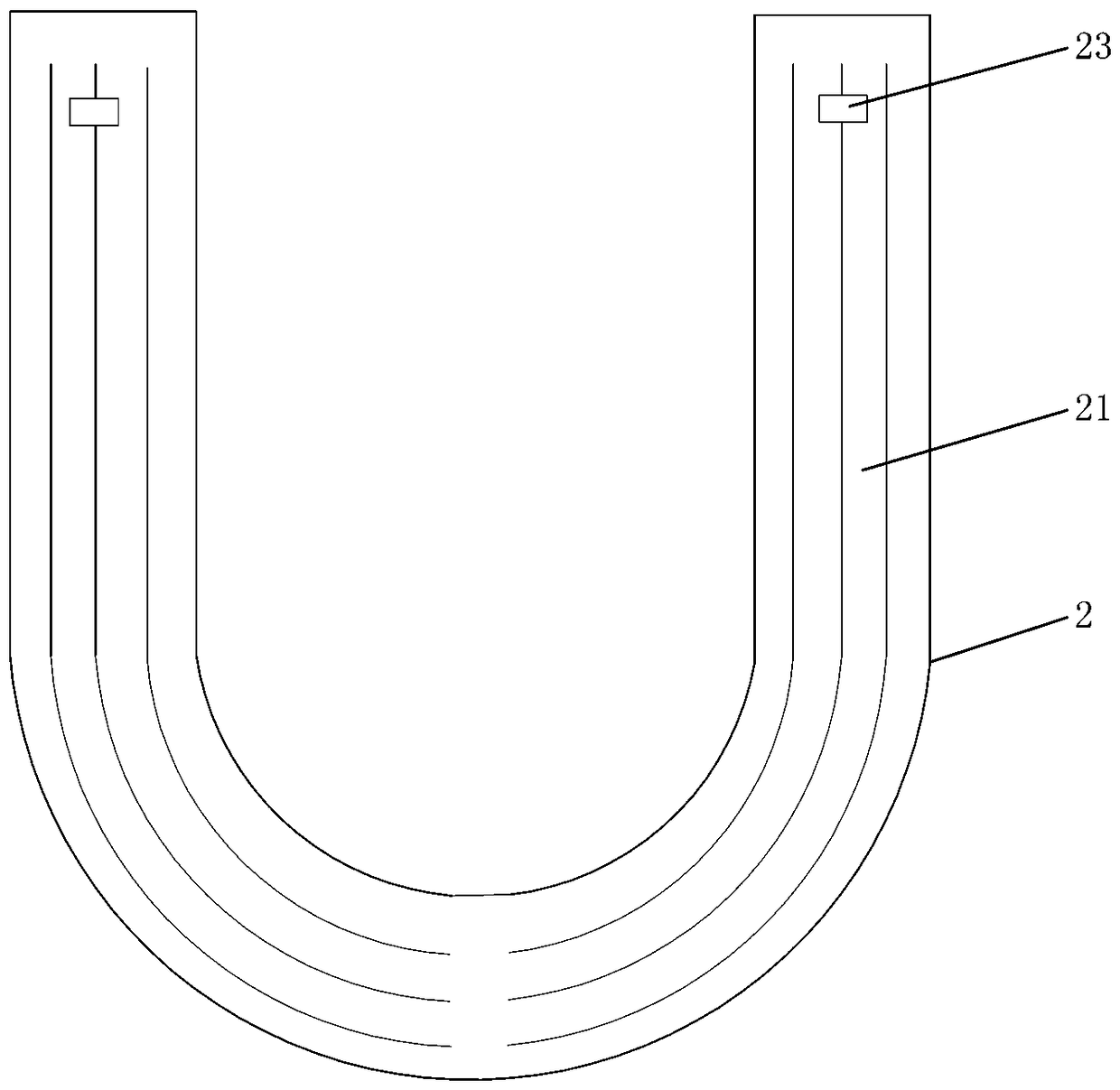

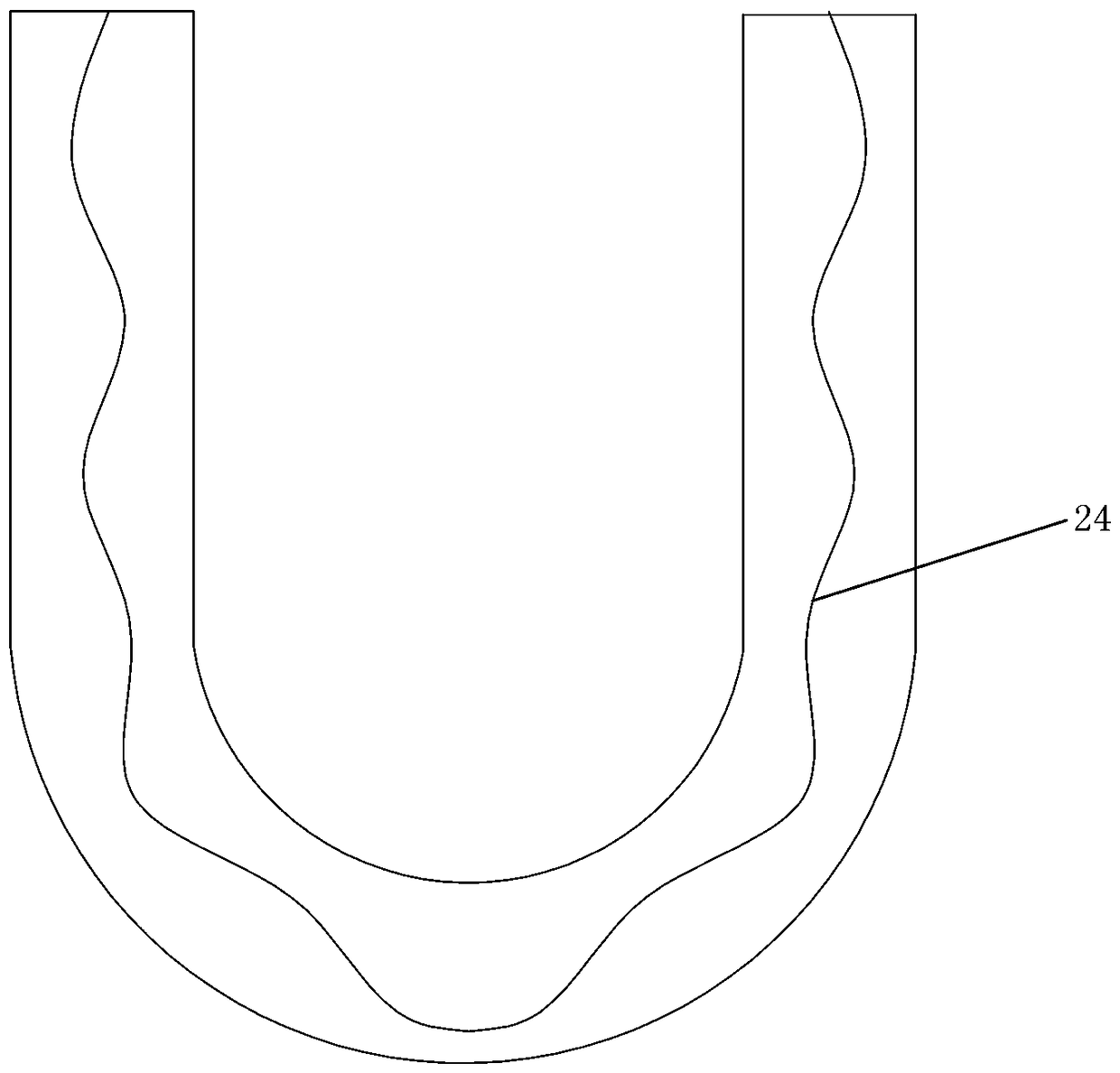

[0060] Step 2: Inject the composite resin masterbatch onto the side of the metal layer 2 on which the diversion groove 21 is formed through the nano-injection molding process, so as to form the seat surface layer of the toilet seat; 23 is equipped with a seating detection sensor and a temperature sensor, and after the seating detection sensor and the temperature sensor are fixed in the notch, the nano injection molding operation is carried out.

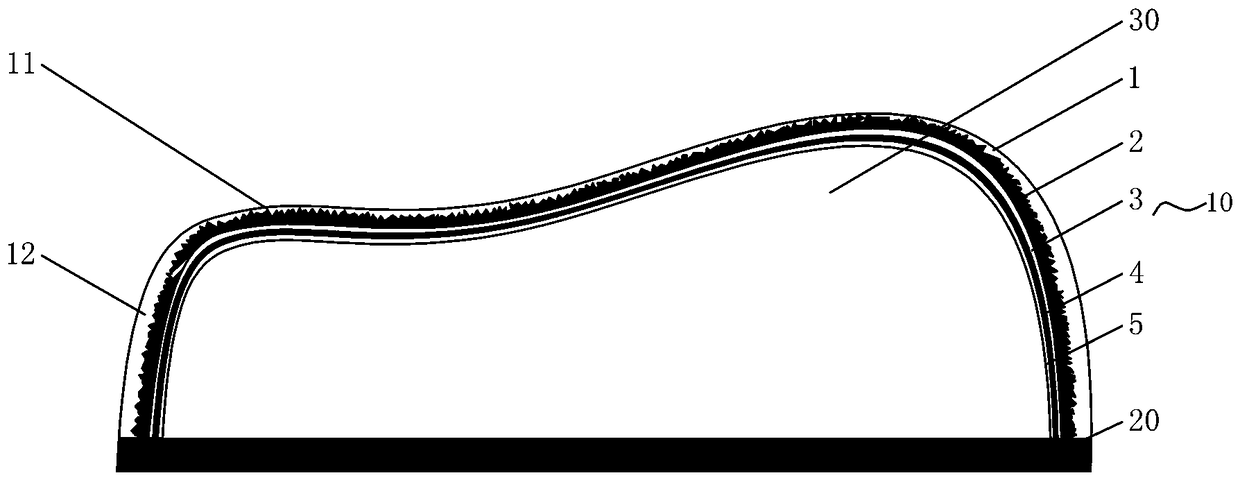

[0061] Step 3: Glue the heating member 3 to the other side of the metal layer 2 to prepare the upper plate 10 of the seat ring; this step also includes gluing the heat insulating material on the lower surface of the heating member 3, and bonding the heat insulating material to the lower surface of the heat insulating material. Heat-reflecting materials are glued on the lower surface to form the heat-...

Embodiment 2

[0074] Specifically include the following steps:

[0075] Step 1: preparing a mixed solution of methyl methacrylate prepolymer;

[0076] Step 2: The methyl methacrylate prepolymer mixed solution is polymerized and molded on the metal layer 2 prepared in the above-mentioned method for preparing the metal layer of a toilet seat through a pouring process, and the diversion groove 21 is formed on one side, so as to Form the seat surface layer 1 of the toilet seat; specifically, this step also includes installing a seat detection sensor and a temperature sensor in the notch 23, and after the seat detection sensor and the temperature sensor are fixed in the notch, the pouring operation is performed .

[0077] Step 3: Glue the heating member 3 to the other side of the metal layer 2 to prepare the upper plate 10 of the seat ring; this step also includes gluing the heat insulating material on the lower surface of the heating member 3, and bonding the heat insulating material The lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com