Electrostatic dust removing device for high-temperature coal gas

An electrostatic precipitator and coal gas technology, applied in the field of high-temperature dust removal, can solve the problems of electrostatic precipitator prone to breakdown, enhanced adhesion of dust particles, and reduced particle charging efficiency, so as to improve the quality of condensed tar and other gasification products , Improve energy utilization efficiency and purify gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific examples, but the protection scope of the present invention is not limited thereto.

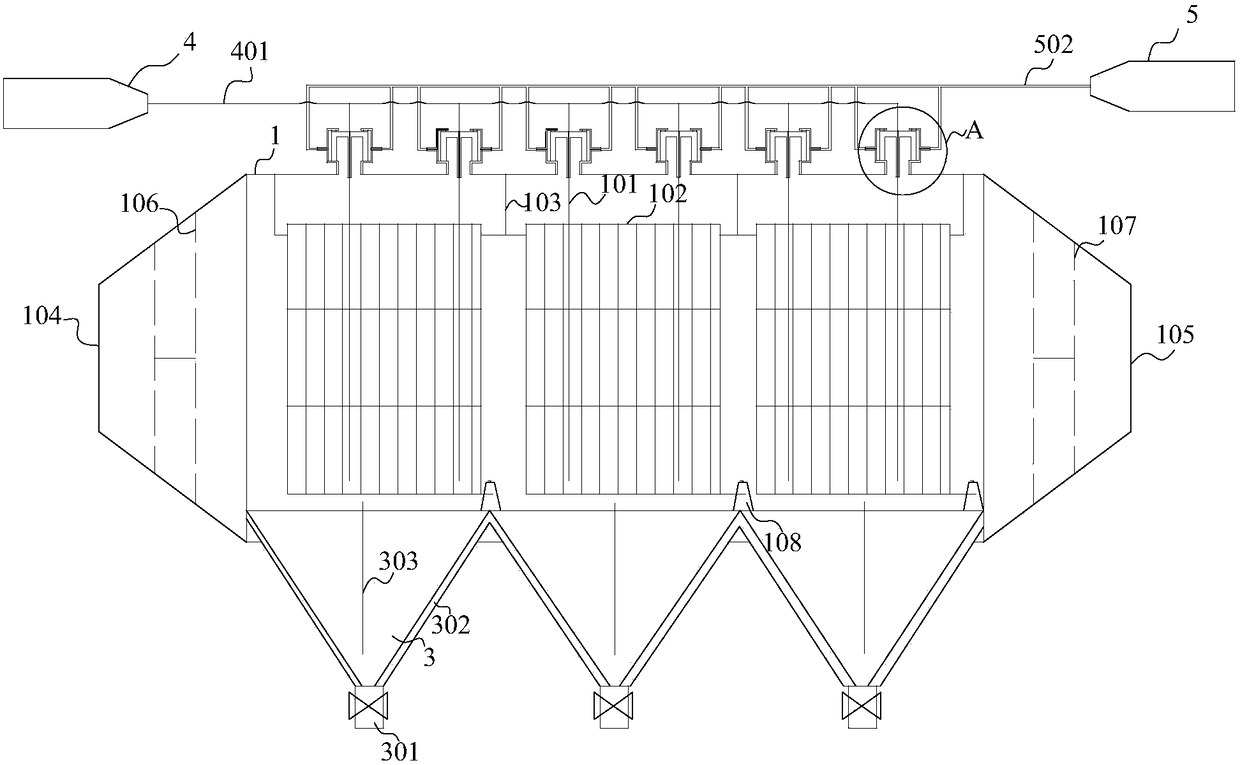

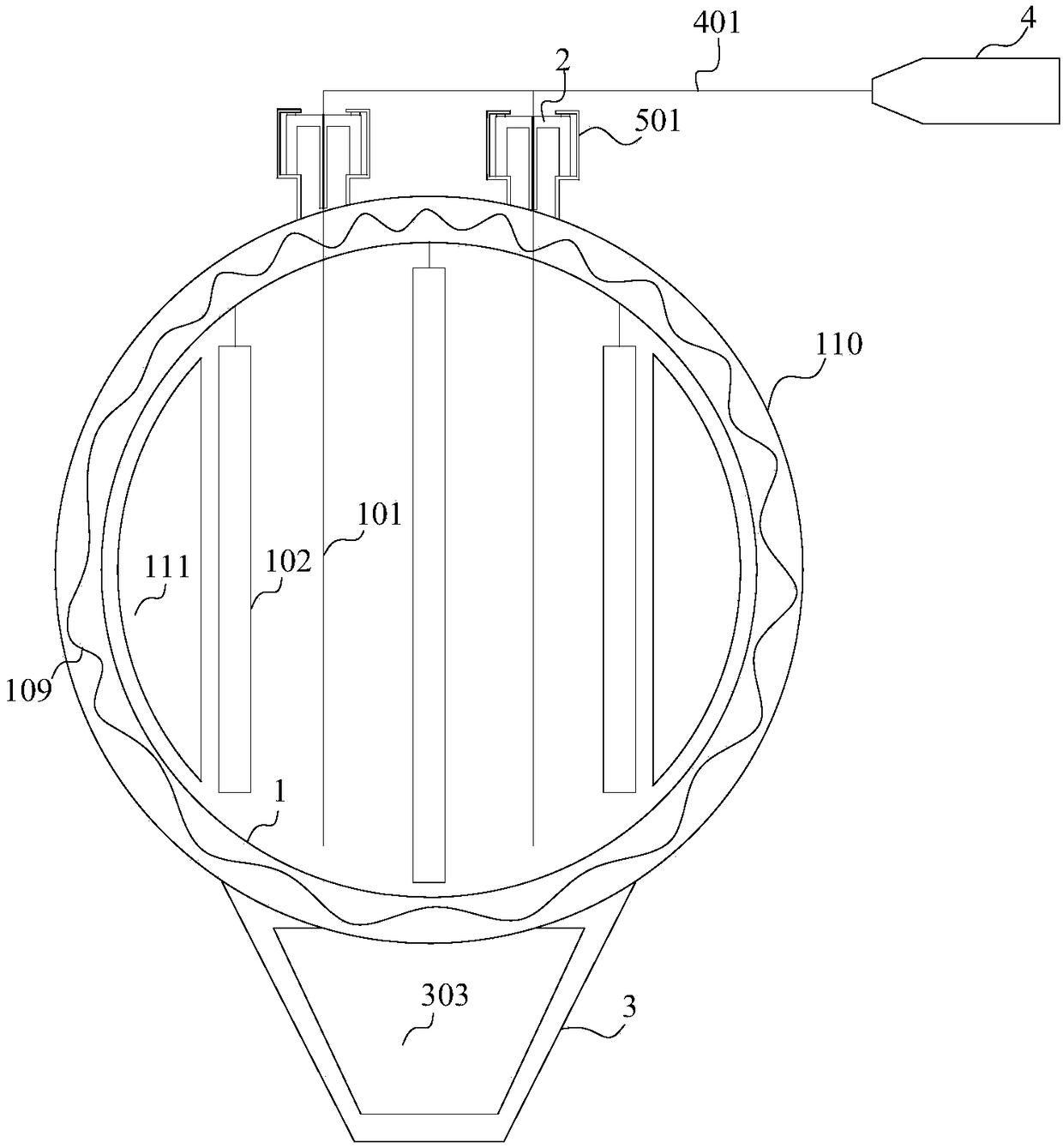

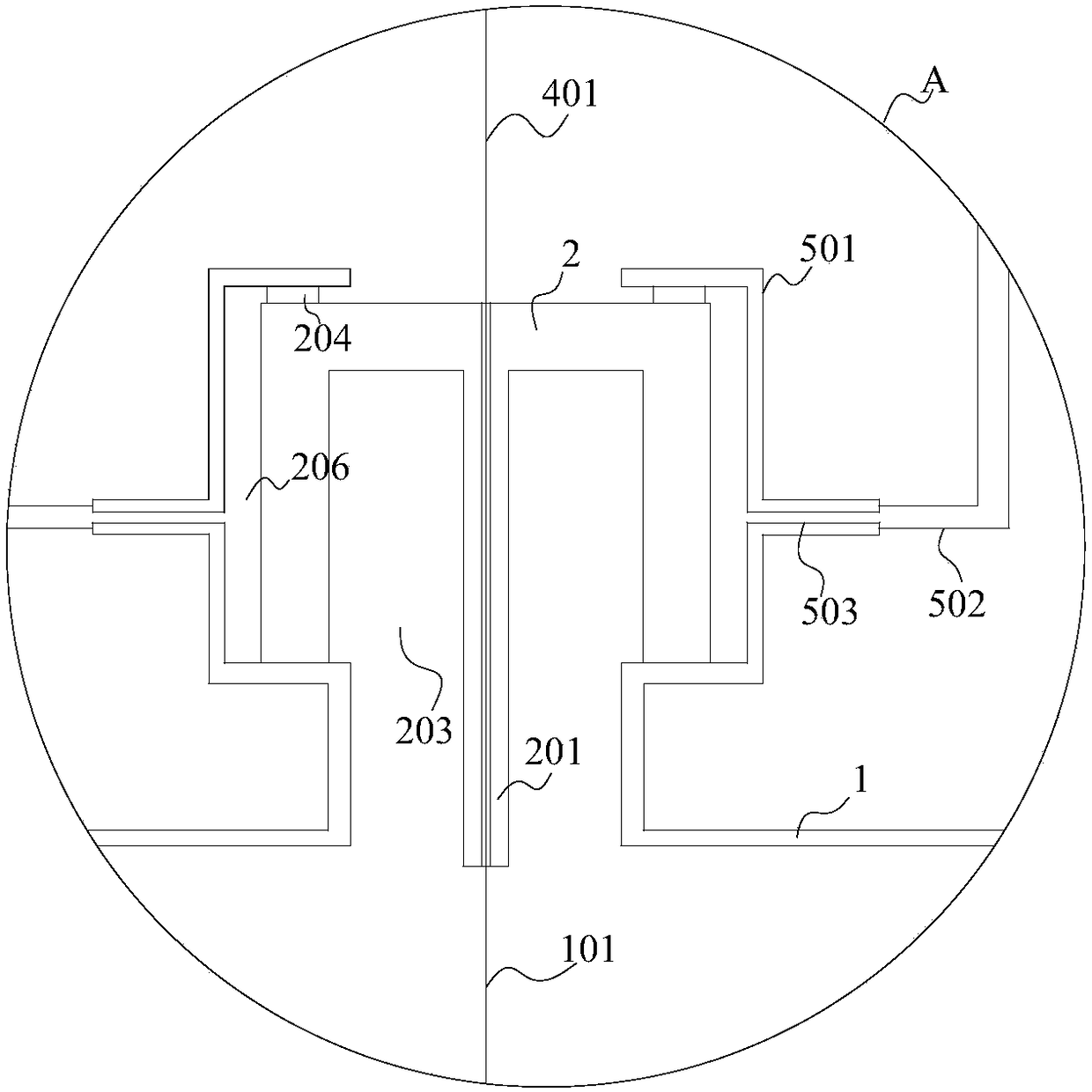

[0043] Such as figure 1 and 2 The shown electrostatic precipitator for high-temperature pyrolysis gas includes: a casing 1 with a gas inlet and outlet, an ash hopper 3 arranged at the bottom of the casing 1, an electrode wire 101 and a dust collecting electrode arranged in the casing 1 The plate 102 , the insulator 2 used to insulate the electrode wire 101 from the casing 1 , the hot gas blowing mechanism used to blow the insulator 2 , and the high voltage power supply 4 connected to the electrode wire 101 .

[0044] The middle of the housing 1 is a hollow cylinder, and the two ends of the hollow cylinder are respectively tapered gas inlet 104 and gas outlet 105 . The electrostatic precipitator adopts a cylindrical shell to prevent deformation caused by high-temperature th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com