Mine sewage flocculant and preparation method thereof

A flocculant and sewage technology, applied in the field of mine sewage flocculant and its preparation, can solve the problems of human health hazards, general treatment effect, slow sedimentation speed, etc., to reduce odor, promote strong compatibility, and add small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

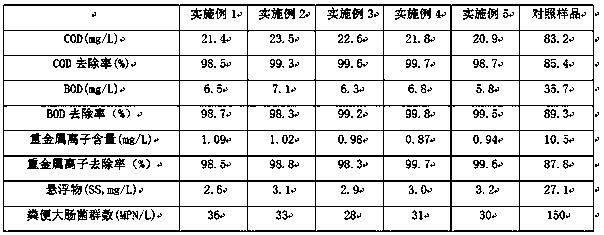

Examples

Embodiment 1

[0029] Divide 50-60 parts of melamine into 3 parts, the first part of melamine is 20 parts by weight, the second part of melamine is 18 parts by weight, and the third part of melamine is 18 parts by weight;

[0030] Preparation of modified melamine: Add 6 parts of formaldehyde and 28 parts of ethylene glycol into a three-necked flask, adjust the pH to 8 with triethanolamine, raise the temperature to 64°C while stirring, then add 20 parts of melamine first, and raise the temperature to 80°C. React for 37 minutes, then add 18 parts of melamine, continue the reaction, react for 60 minutes, then add 18 parts of melamine, and react at constant temperature until the water number is 3.0, add 10% caprolactam, react for 8 minutes, cool down to 62 ° C, slowly add 5% H 2 o 2 , and continue to use triethanolamine to adjust the pH value to 8; when the H2O2 reaction is complete (that is, no bubbles are generated in the reaction solution), stop the reaction, lower the temperature to 40°C, ad...

Embodiment 2

[0033] Divide 50-60 parts of melamine into 3 parts, the first part of melamine is 19 parts by weight, the second part of melamine is 20 parts by weight, and the third part of melamine is 20 parts by weight;

[0034] Preparation of modified melamine: Add 5 parts of formaldehyde and 30 parts of ethylene glycol into a three-necked flask, adjust the pH to 8 with triethanolamine, raise the temperature to 63°C while stirring, then add 19 parts of melamine first, and raise the temperature to 75°C. React for 35 minutes, then add 20 parts of melamine, continue the reaction, react for 70 minutes, then add 20 parts of melamine, and react at constant temperature until the water number is 3.0, add 10% caprolactam, react for 10 minutes, cool down to 65 ° C, slowly add 5% H2O2, And continue to use triethanolamine to adjust the pH value to 8; when the H2O2 reaction is complete (that is, no bubbles are generated in the reaction solution), stop the reaction, lower the temperature to 40°C, add 50...

Embodiment 3

[0037] Divide 50-60 parts of melamine into 3 parts, the first part of melamine is 20 parts by weight, the second part of melamine is 18 parts by weight, and the third part of melamine is 20 parts by weight;

[0038] Preparation of modified melamine: Add 5.5 parts of formaldehyde and 20 parts of ethylene glycol into a three-necked flask, adjust the pH to 8 with triethanolamine, raise the temperature to 65°C while stirring, then add 20 parts of melamine first, and raise the temperature to 76°C. React for 40 minutes, then add 18 parts of melamine, continue the reaction, react for 65 minutes, then add 20 parts of melamine, and react at constant temperature until the water number is 3.0, add 10% caprolactam, react for 9 minutes, cool down to 63 ° C, slowly add 5% H2O2, And continue to use triethanolamine to adjust the pH value to 8; when the H2O2 reaction is complete (that is, no bubbles are generated in the reaction solution), stop the reaction, lower the temperature to 40 ° C, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com