Preparation process of cement-based muck concrete

A concrete product and cement-based technology, which is applied in the fields of concrete preparation and cement-based slag concrete preparation technology, can solve the problems of high production cost of grinding slag, difficulty in recycling construction slag, etc. Significant social and economic benefits, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

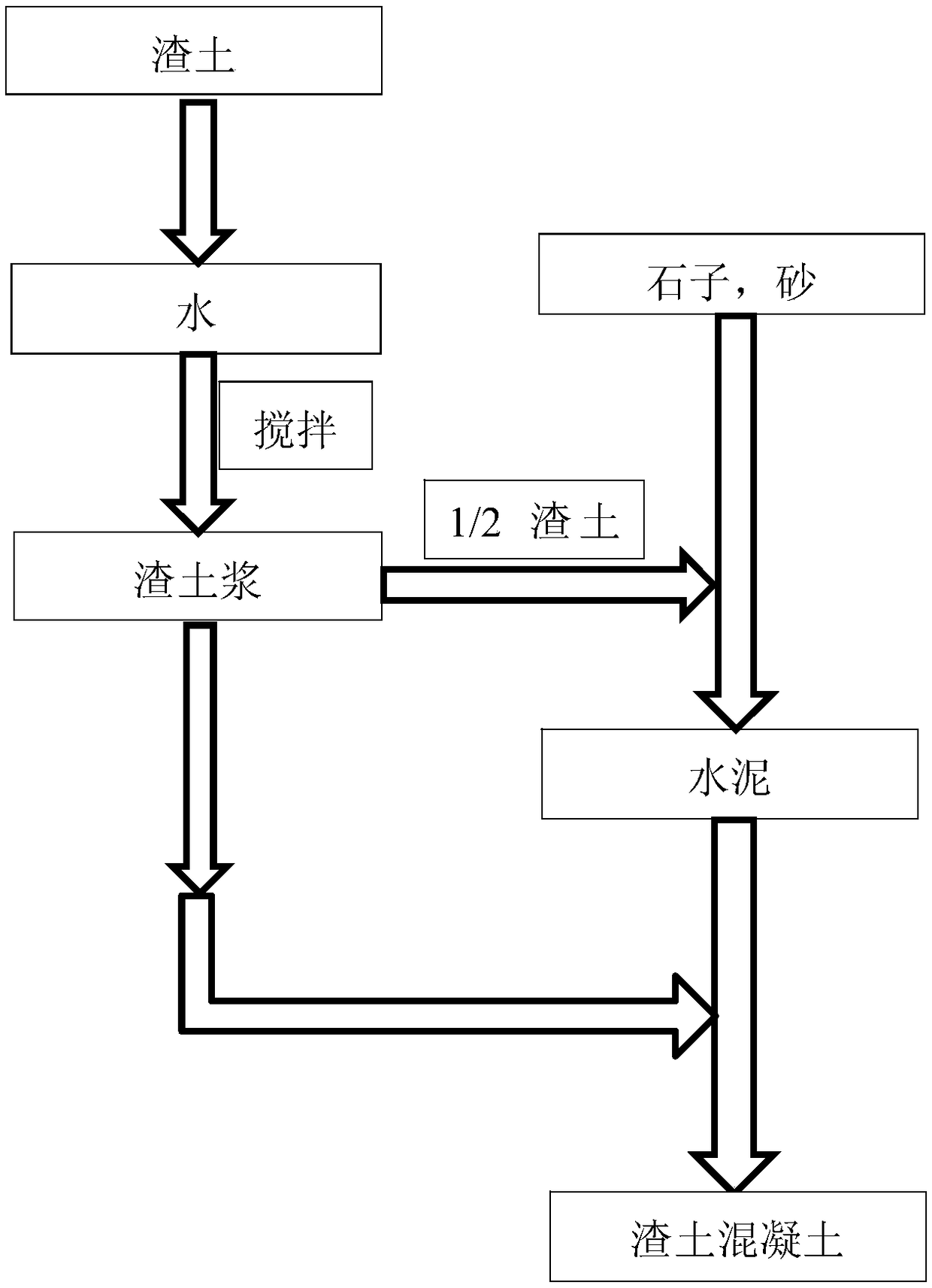

Image

Examples

Embodiment 1

[0028] Material standard:

[0029] Cement is not lower than P.O42.5; water reducing agent is 35%;

[0030] The fineness modulus of sea sand is 2.9; the bulk density is 1360kg / m 3 ;The apparent density is 2690kg / m 3 ;

[0031] The particle size of the stone is 5-25mm, and the bulk density is 1451kg / m 3 , the apparent density is 2680kg / m 3 .

[0032] The untreated waste construction dregs in Xiqing District, Tianjin were taken, and the materials were selected according to the mass ratio. Cement: muck: water: sand: gravel is 1:0.1:0.4:2.2:3.2, and the amount of water reducing agent is 0.7% of the total mass of cement and muck. The water-cement ratio is 0.4.

[0033] Put the water and the construction waste slag collected on site into the mixer B, and stir for 2 minutes at the speed of 240r / min to obtain the slag slurry.

[0034] Take another mixer A, put stones and sand into it, mix well; transfer 1 / 2 of the muck slurry in mixer B to mixer A, and stir for 1 minute; then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com