Preparation method of chiral optical pure p-toluenesulfinamide

A technology of toluene sulfinamide and sodium toluene sulfinate, which is applied in the field of preparation of chiral optical pure p-toluene sulfinamide, can solve the problems of high price of LiHMDS, large solvent ratio, unfavorable large-scale production, etc., and achieve atom utilization High efficiency, improved alkalinity, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

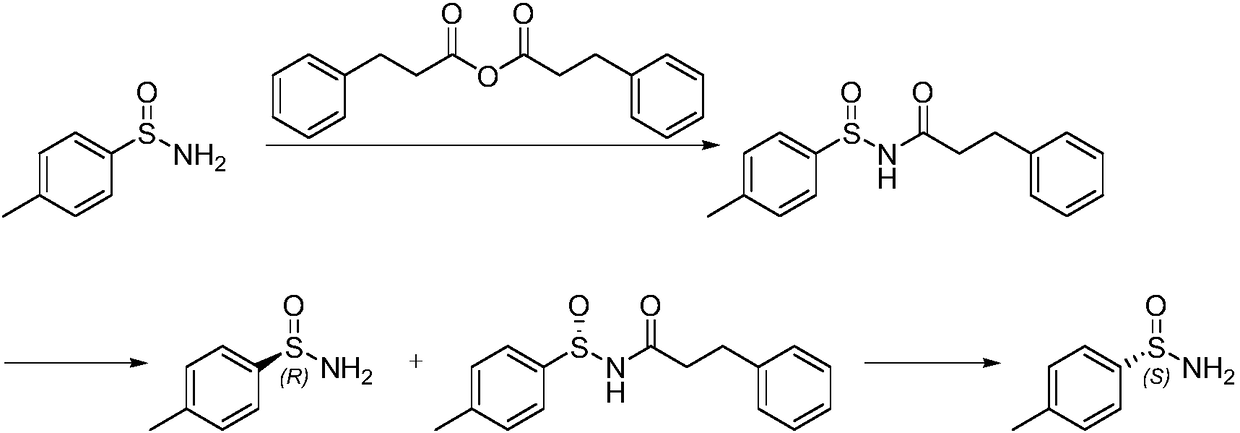

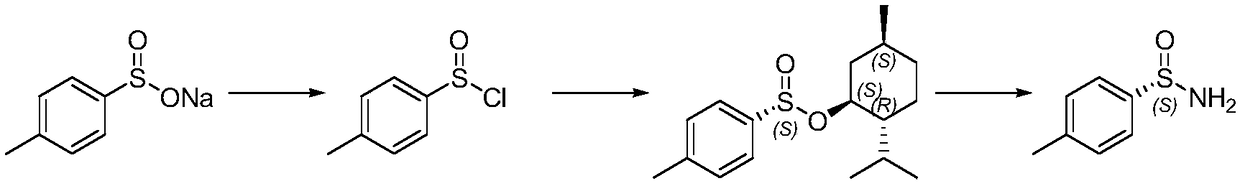

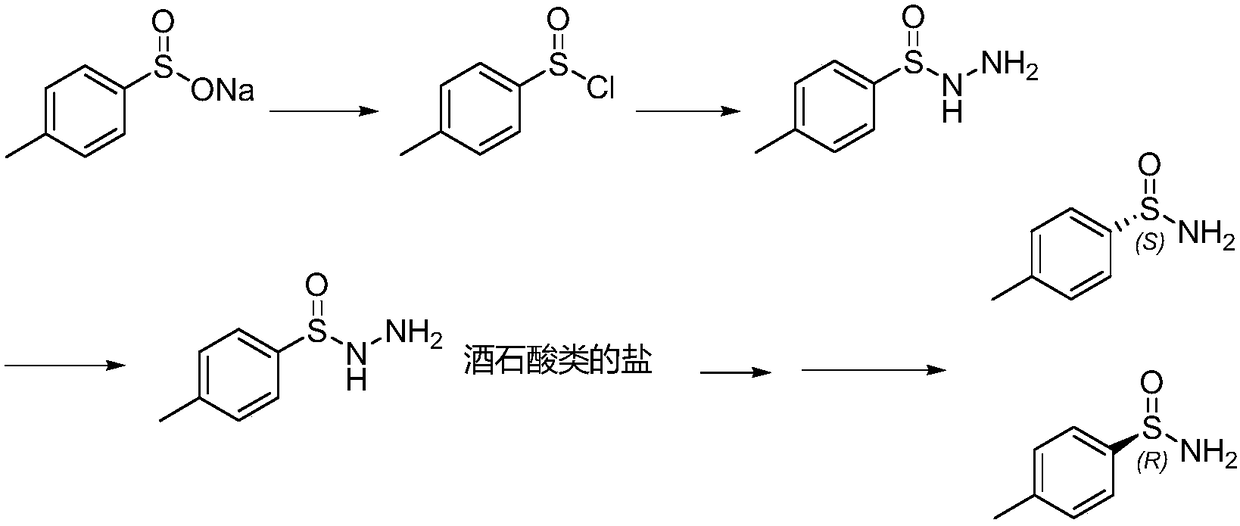

Method used

Image

Examples

Embodiment 1

[0042] The first step: the synthesis of p-toluenesulfinyl chloride.

[0043] (1) Put 267g of toluene, 53.4g of sodium p-toluene sulfinate and 0.1g of N,N-dimethylformamide into a dry and clean 500mL four-necked bottle with an addition funnel, add 57.5g of thionyl chloride dropwise at room temperature, React at 55-65°C for 4 hours, take samples for GC or HPLC detection after derivatization, the raw material is less than 0.3%, concentrate under reduced pressure, replace once with 150g of toluene, then add 50g of toluene to dilute for later use. The external standard yield is 94%.

[0044] (2) Put 267g of benzene, 53.4g of sodium p-toluenesulfinate and 0.1g of N,N-dimethylformamide into a dry and clean 500mL four-necked bottle with an addition funnel, add 57.5g of thionyl chloride dropwise at room temperature, and Reaction at 55-65°C for 4 hours, sampled by GC or HPLC after derivatization, the raw material is less than 0.3%, concentrated under reduced pressure, replaced once wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com