Extraction method and application of millipede oil

An extraction method and technology of malu oil, applied in the application, fat oil/fat production, fat production, etc., can solve the problem of no related reports, and achieve the effects of increasing the extraction rate, improving immunity, and improving physiological metabolism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

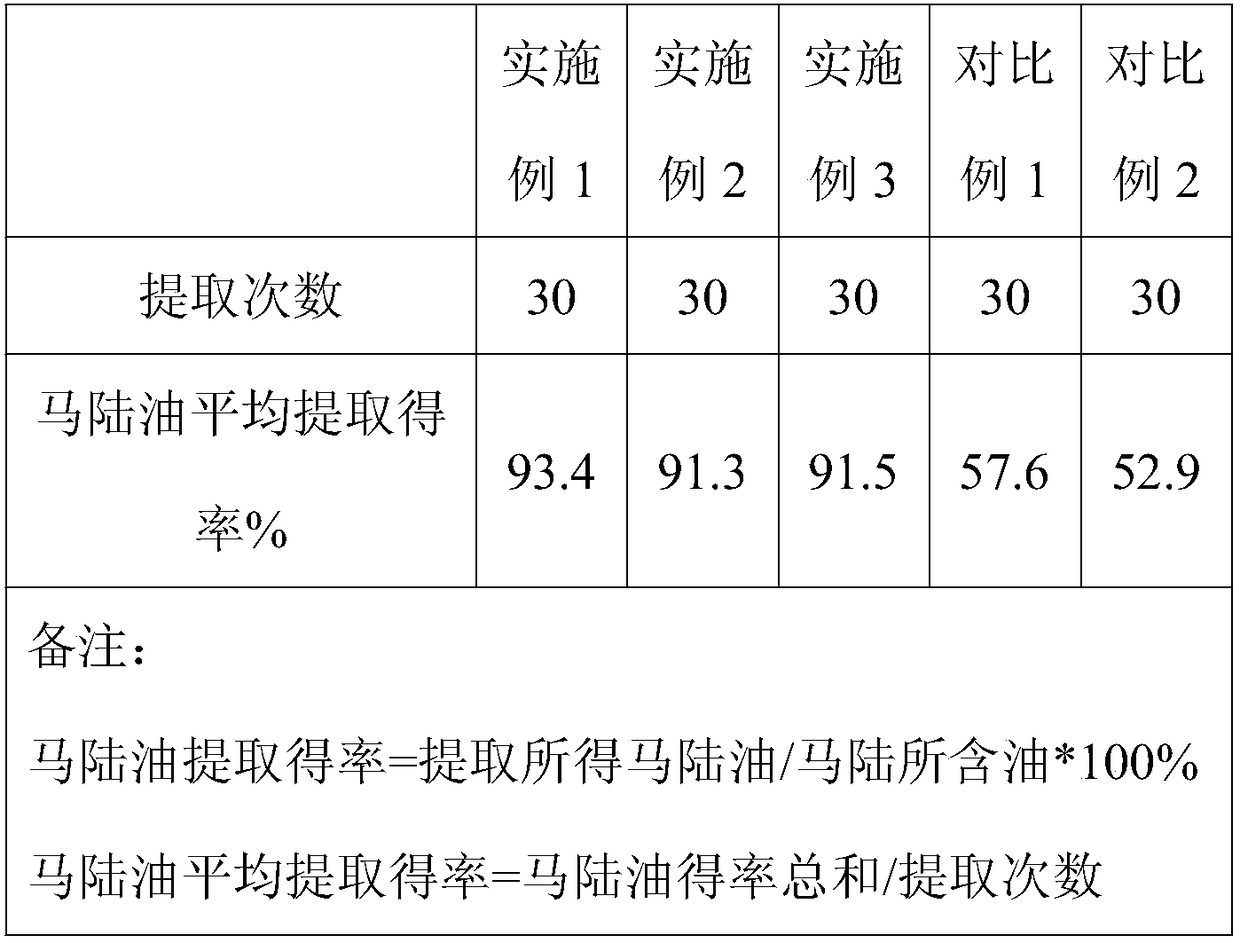

Examples

Embodiment 1

[0026] A method for extracting oil from millipede, comprising the steps of:

[0027] (1) collect millet, scald to death with hot water, dry, crush and pass through a 50-mesh sieve to obtain millet powder;

[0028] (2) With the millipede powder of step (1), under the extrusion conditions that the screw speed is 85r / min and the hole diameter of the touch head is 9mm, after extrusion and puffing, cool to room temperature and set aside;

[0029] (3) Take the millipede powder expanded in step (2), add ethyl acetate with a mass volume ratio of 15, carry out ultrasonic extraction, then put it into a separation kettle for separation, separate at 55° C. and a pressure of 60 bar in separation kettle I for 3 hours, Separation at 45°C and a pressure of 50bar in separation kettle II for 3h, and collect the separation liquid;

[0030] (4) Extract the separation liquid of step (3) with food-grade carbon dioxide to obtain Malu oil.

Embodiment 2

[0032] A method for extracting oil from millipede, comprising the steps of:

[0033] (1) collect millet, scald to death with hot water, dry, crush and pass through a 60-mesh sieve to obtain millet powder;

[0034] (2) With the millipede powder of step (1), under the extrusion condition that the screw speed is 80r / min, and the hole diameter of the touch head is 8mm, after extrusion and puffing, cool to room temperature and set aside;

[0035] (3) Take the millipede powder expanded in step (2), add ethyl acetate with a mass volume ratio of 10, carry out ultrasonic extraction, then put it into a separation kettle for separation, separate at 50° C. and a pressure of 55 bar in separation kettle I for 2 hours, Separation at 40°C and a pressure of 45bar in separation kettle II for 2h, and collect the separation liquid;

[0036] (4) Extract the separation liquid of step (3) with food-grade carbon dioxide to obtain Malu oil.

Embodiment 3

[0038] A method for extracting oil from millipede, comprising the steps of:

[0039] (1) collect millet, scald to death with hot water, dry, crush and pass through a 40-mesh sieve to obtain millet powder;

[0040] (2) With the millipede powder of step (1), under the extrusion condition that the screw speed is 90r / min and the hole diameter of the touch head is 10mm, after extrusion and puffing treatment, cool to room temperature and set aside;

[0041] (3) Take the millipede powder expanded in step (2), add ethyl acetate with a mass volume ratio of 20, carry out ultrasonic extraction, then put it into a separation kettle for separation, separate at 60° C. and a pressure of 65 bar in separation kettle I for 4 hours, Separation at 50°C and a pressure of 55bar in separation kettle II for 4h, and collect the separation liquid;

[0042] (4) Extract the separation liquid of step (3) with food-grade carbon dioxide to obtain Malu oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com