Method for identifying aragonite by means of X-ray powder crystal diffraction

An X-ray and aragonite technology, applied in the detection field, can solve the problems of complex operation of the identification method, rare and rare aragonite, unstable aragonite, etc., and achieve the effects of uniform distribution of elements, elimination of stress, and improvement of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

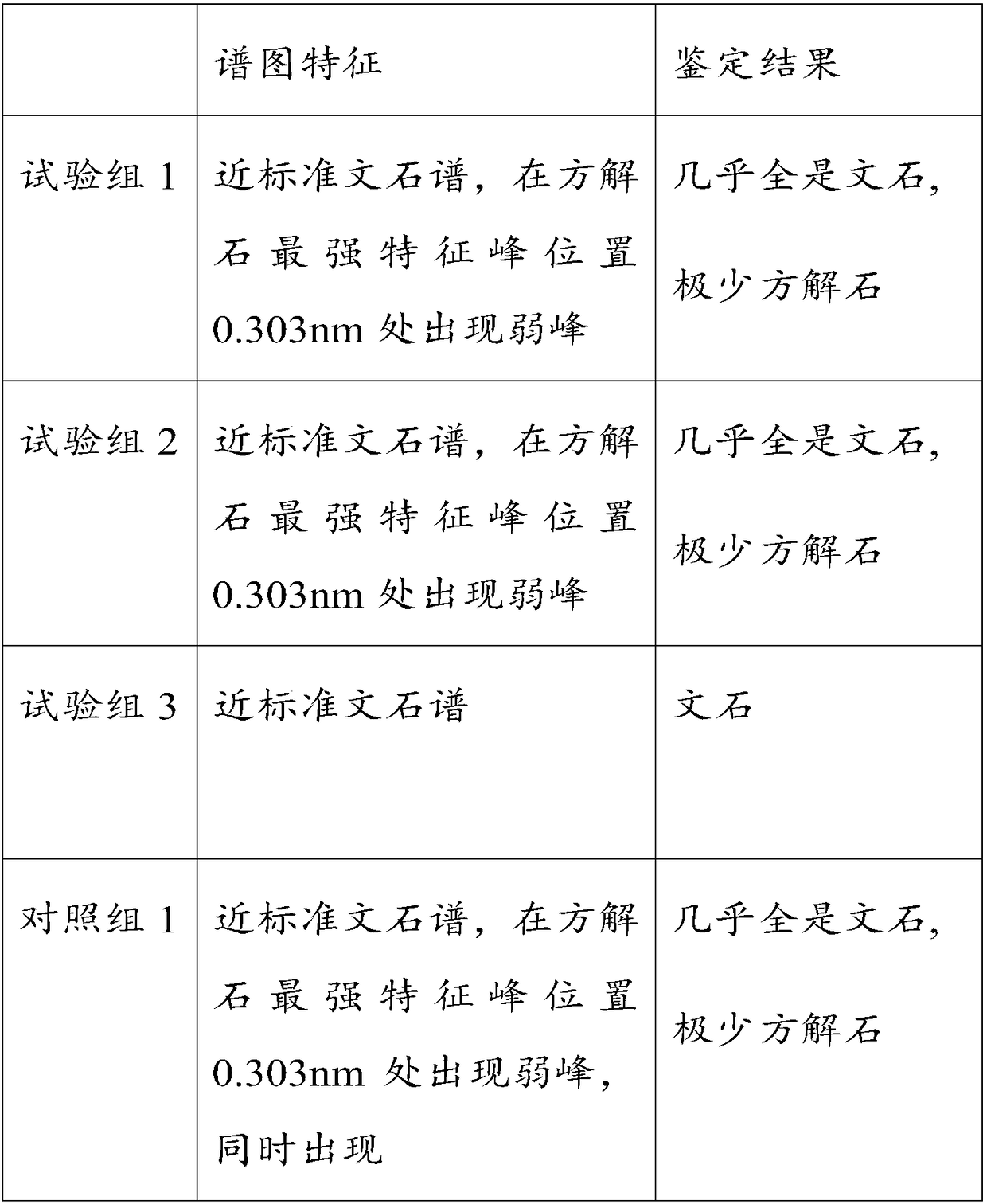

Examples

Embodiment 1

[0035] A method for identifying aragonite by X-ray powder crystal diffraction, comprising:

[0036] After the aragonite sample is cleaned and air-dried, it is ground at 0° C. until the particle size of the aragonite sample after grinding is 10 um ≤ 15 um, and the aragonite sample powder is obtained.

[0037] Mix the aragonite sample powder with alcohol, ultrasonically disperse for 2s under the condition of ultrasonic frequency of 23KHz, and then coat it on the glass sample. The thickness of the aragonite sample coated on the glass sample is 1.6mm. After drying, X-ray powder diffraction is carried out by SIMENSD500 X-ray diffractometer under the conditions of tube voltage 35kV, tube current 35mA, 2θ scanning speed 2° / s, scanning range 24-73°, and the sample X-ray powder diffraction data.

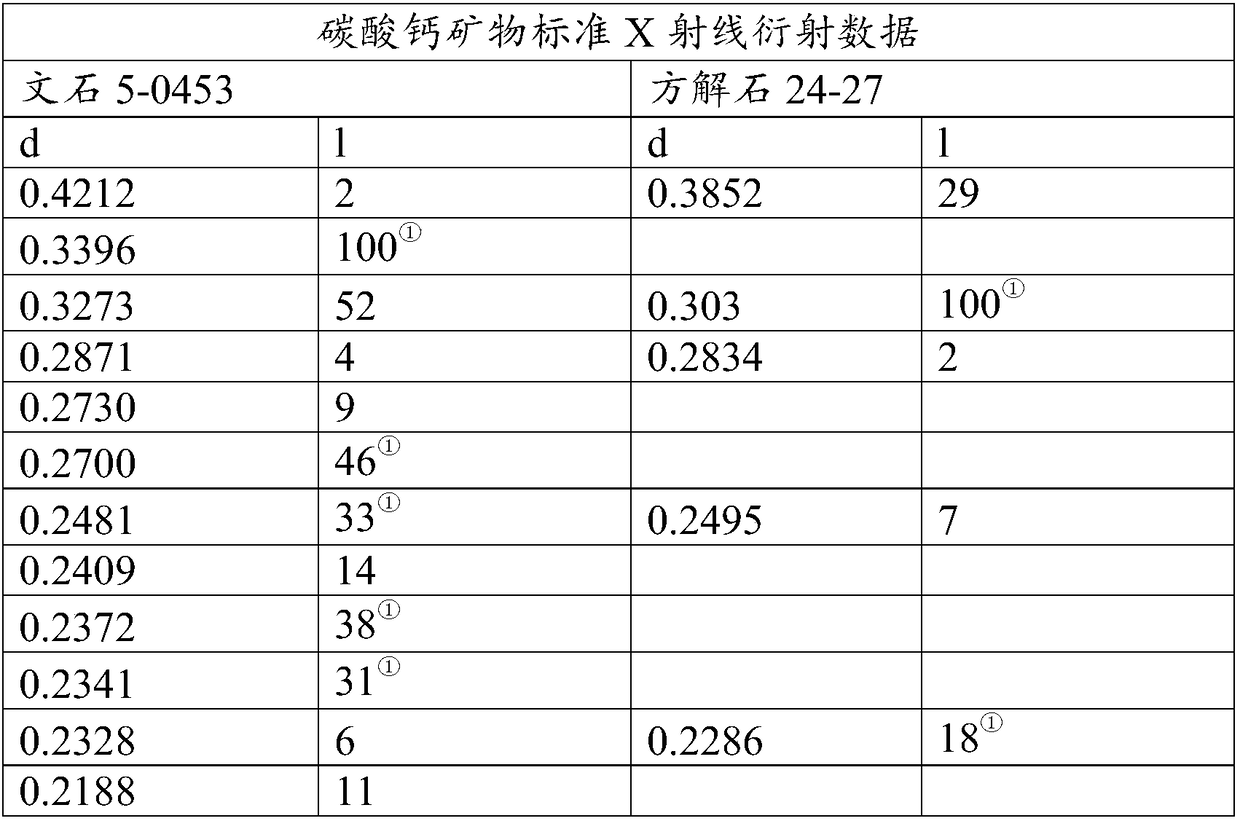

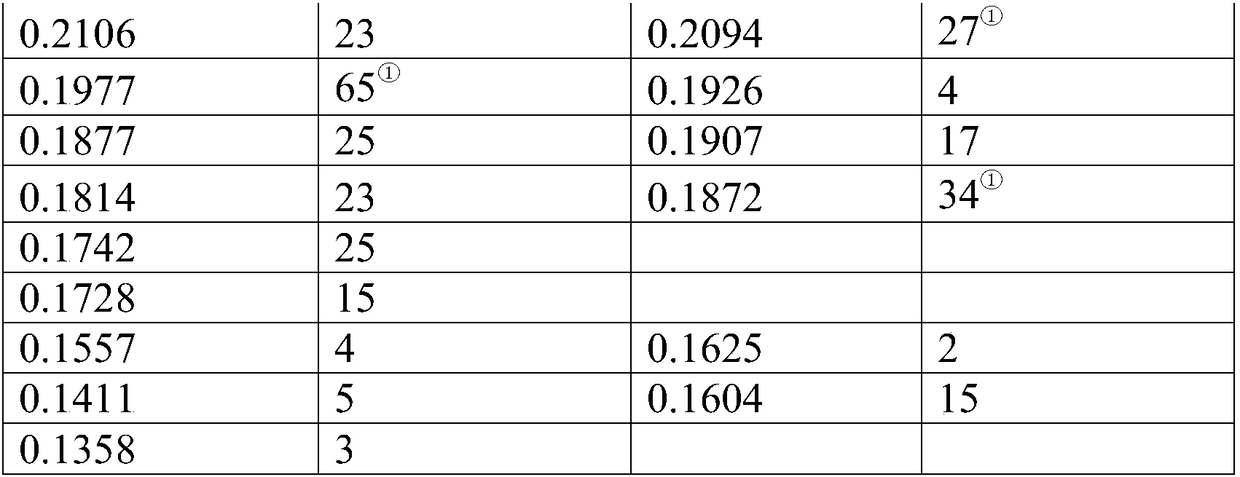

[0038] Compare the X-ray powder crystal diffraction data of the obtained aragonite sample with the national standard X-ray powder crystal diffraction data of aragonite for identification.

Embodiment 2

[0040] A method for identifying aragonite by X-ray powder crystal diffraction, comprising:

[0041] After the aragonite sample is cleaned and air-dried, it is ground at 0° C. until the particle size of the aragonite sample after grinding is 10 um ≤ 15 um, and the aragonite sample powder is obtained.

[0042] Spray the glue in alcohol, mix it with the ground aragonite sample, disperse it ultrasonically for 2 seconds under the condition of ultrasonic frequency of 23KHz, and apply it to the glass sample. The thickness of the aragonite sample coated on the glass sample is 1.6 mm, after coating, after drying at 50°C, X-ray powder is carried out by SIMENSD500 X-ray diffractometer under the conditions of tube voltage 35kV, tube current 35mA, 2θ scanning speed 2° / s, scanning range 24-73° Crystal diffraction to obtain sample X-ray powder crystal diffraction data.

[0043] Wherein, the total amount ratio of the glue solution to the ground aragonite sample is 1:13, and the volume ratio of...

Embodiment 3

[0046] A method for identifying aragonite by X-ray powder crystal diffraction, comprising:

[0047] After the aragonite sample is cleaned and air-dried, it is ground at 3° C. until the particle size of the aragonite sample after grinding is 11 um≤14 um, and the aragonite sample powder is obtained.

[0048] Spray and add glue in alcohol, mix it with the ground aragonite sample, ultrasonically disperse for 2s under the condition of ultrasonic frequency of 25KHz, and then apply it to the glass sample, the thickness of the aragonite sample coated on the glass sample is 2mm , after coating and drying at 54°C, X-ray powder crystals were carried out by SIMENSD500 X-ray diffractometer under the conditions of tube voltage 35kV, tube current 35mA, 2θ scanning speed 2° / s, scanning range 24-73° Diffraction to obtain sample X-ray powder crystal diffraction data.

[0049] Wherein, the total amount ratio of the glue solution to the ground aragonite sample is 1:14, and the volume ratio of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com