Optical component surface profile processing process and parameter selection method and application method thereof

A technology for optical components and parameter selection, applied in special data processing applications, electrical digital data processing, instruments, etc., can solve problems such as suboptimal, and achieve the effect of improving accuracy, avoiding manual judgment, and quickly converging parameter selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

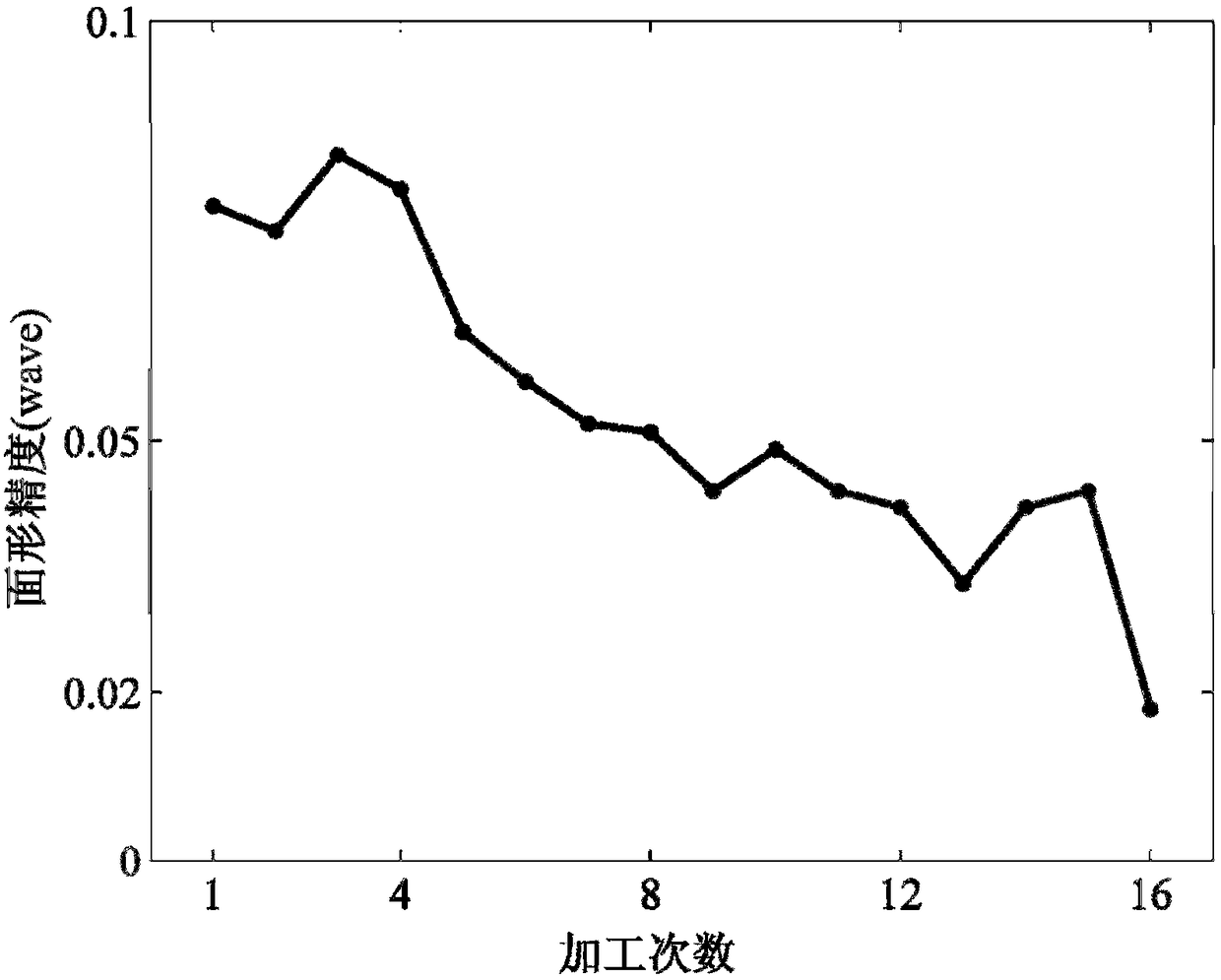

[0024] The following will take a Φ540mm SiC off-axis aspheric mirror as an example to further explain the process, parameter selection and application method of the surface shape processing of the optical element of the present invention.

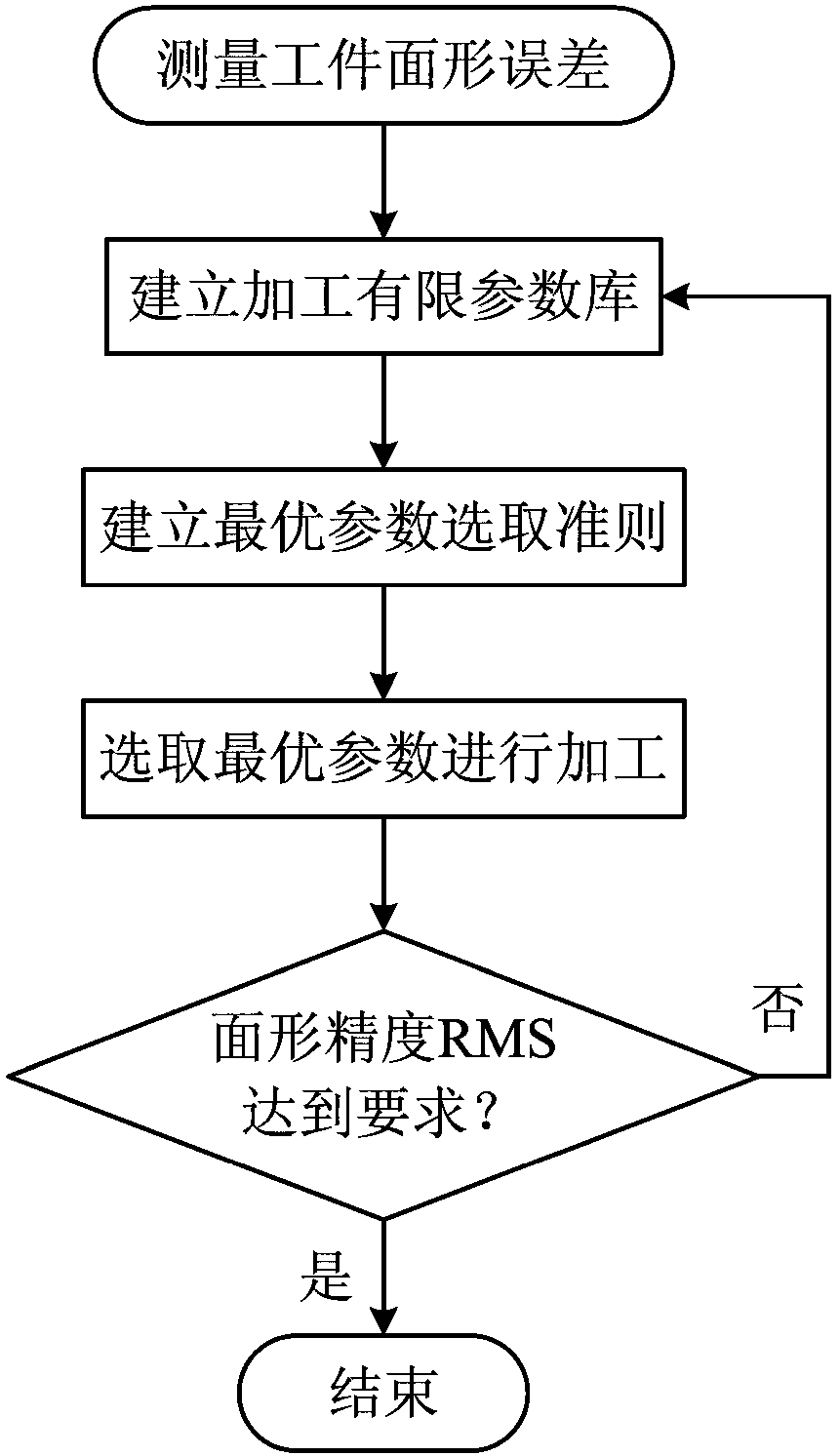

[0025] Such as figure 1 As shown, the implementation steps of the process and parameter selection method of optical element surface processing in this embodiment include:

[0026] 1) Establishing a processing limited parameter library for the target optical component, the processing limited parameter library includes at least two or more groups of processes and parameters for surface processing of the target optical component;

[0027] 2) Calculate the modification efficiency FA of each group of processes and parameters;

[0028] 3) Select a group of processes and parameters with the largest modification efficiency FA value as the output optimal process and parameters.

[0029] In the present embodiment, in step 2), the functional express...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com