3D printing flexible socket with adaptability

A 3D printing, self-adaptive technology, applied in the field of medical devices, can solve the problems of exacerbating the discomfort of prosthetics, difficulty in ensuring accuracy, and single hardness, so as to shorten the preparation process and time, reduce weight, and improve wearing comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

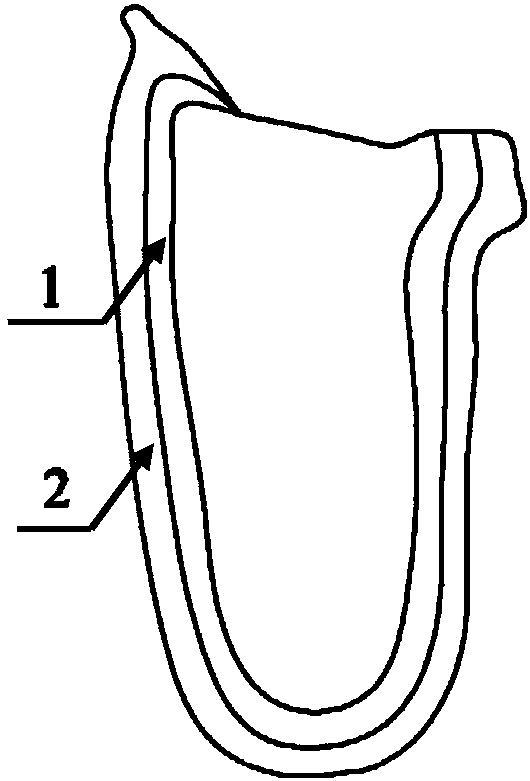

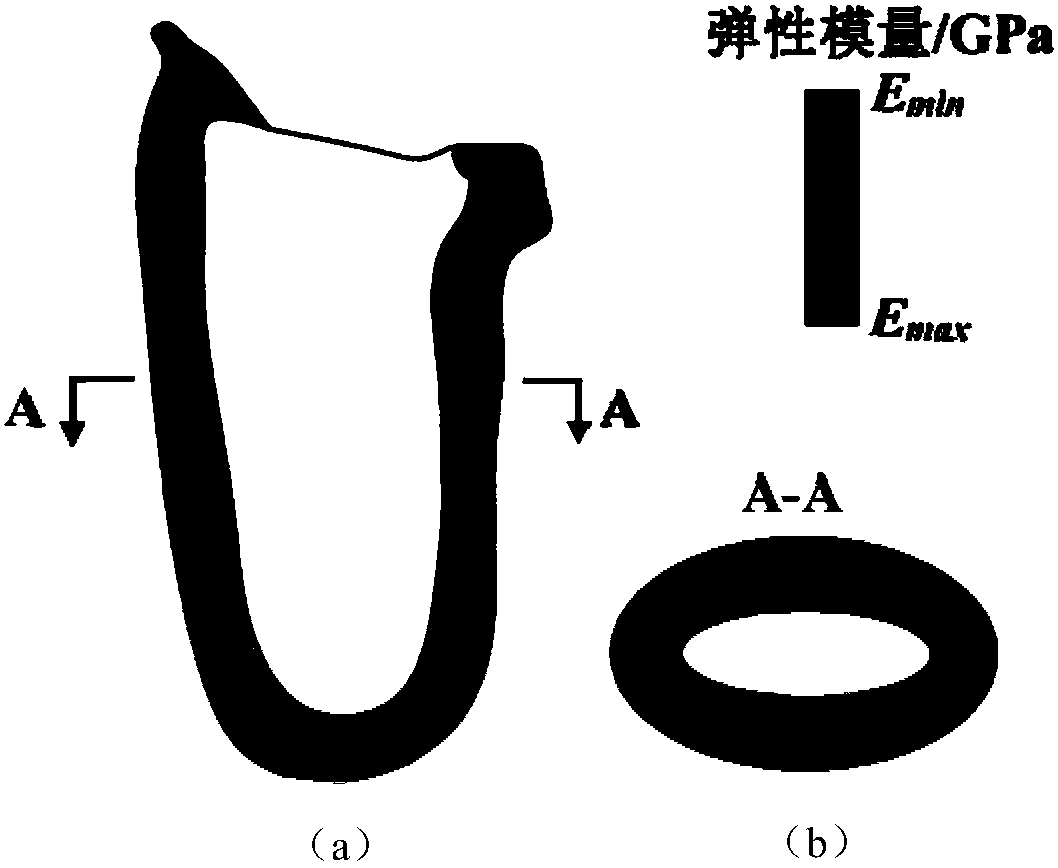

[0022] like figure 1 As shown, it is a structural diagram of the prosthetic socket proposed by the present invention, including the socket inner cavity 1 and the socket shell 2; the prosthetic socket inner cavity 1 and the socket shell 2 are integrally printed and formed by a 3D printer. The printing material of the inner cavity 1 of the receiving cavity is made of thermoplastic polyurethane rubber; the printing material of the outer shell of the receiving cavity 2 is made of carbon fiber reinforced polylactic acid composite material.

[0023] According to the fused deposition modeling experiment to measure the mechanical property data of the material under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com