Small laneway slagging-off and loading machine

A technology for loading and unloading shafts, which is applied in the field of crawler-type small loading and unloading machines for shafts, achieving the effects of novel structural design, improved construction efficiency, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

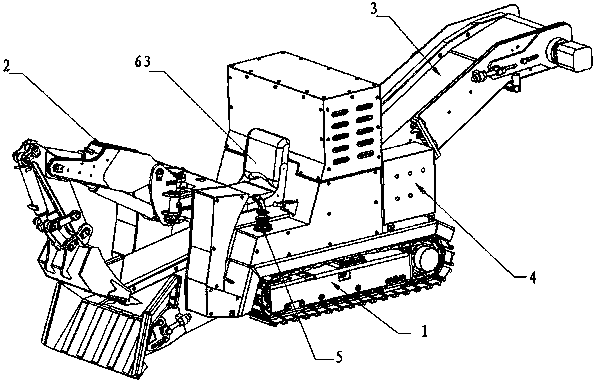

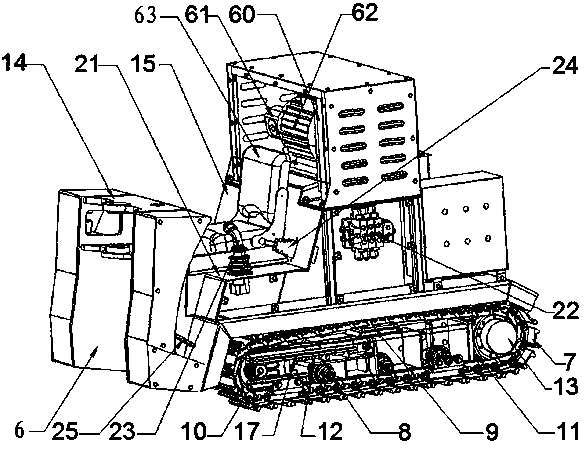

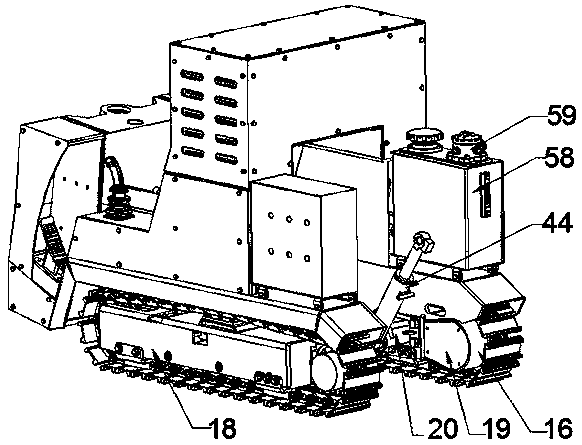

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention mainly includes a vehicle chassis 1, an excavation loading mechanism 2, a conveying and unloading mechanism 3, an electrical control system 4, a hydraulic system and an operating mechanism 5 thereof. The driver's seat 63 is fixed on the vehicle chassis 1 and is located in the middle of the left and right directions of the vehicle chassis 1, which replaces the existing solution of the driver's seat on the side of the vehicle conveying frame of the mining digging-type loader, effectively reducing the overall size of the vehicle. Width, so that it can be better satisfied with small and medium-sized mines or engineering pipelines; the conveying and unloading mechanism 3 is installed on the vehicle chassis 1, placed in a hollow position in the left and right directions of the vehicle chassis 1, and at the lower part of the driver's seat 63; Gear pump 61, motor 62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com