Denitration device and denitration method for flue gas in wet-method gold melting and/or silver melting section

A denitrification and wet process technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of high cost of denitrification methods, and achieve the effect of reducing overall operating costs, reducing operating costs and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

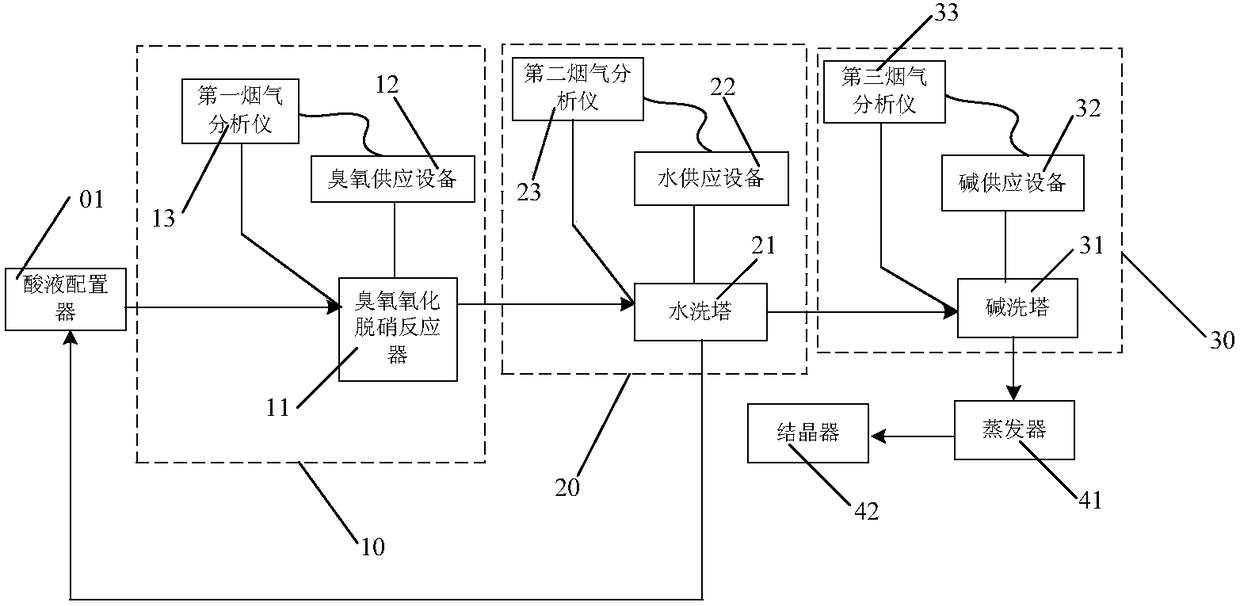

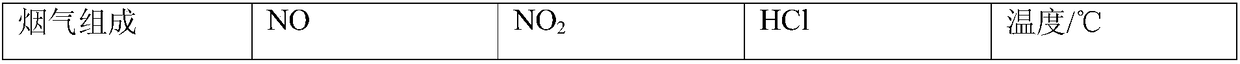

[0052] use figure 1 The de-pinning device shown denitrifies the flue gas from the wet gold and / or silver melting section, that is, performs ozone oxidation and denitration treatment on the flue gas from the wet gold melting and / or silver melting section to obtain oxidized flue gas; Washing the oxidized flue gas to obtain the washed flue gas and dilute acid solution; washing the washed flue gas with an alkaline solution to obtain exhaustable flue gas and absorbed salt solution; and reusing the dilute acid solution to the Wet gold and / or silver melting section. Among them, the online flue gas analyzer is used to detect the composition and temperature of the main nitrogen oxides in the flue gas in real time, as shown in Table 1, and the flue gas treatment capacity is 5500Nm 3 / h.

[0053] Table 1

[0054] Composition of flue gas

NO

NO 2

HCl

temperature / ℃

Concentration (mg / Nm 3 )

620

833

436

45

[0055] In the process of ozo...

Embodiment 2

[0060] use figure 1 The denitration device shown denitrifies the flue gas from the wet gold and / or silver melting section. The composition and temperature of the main nitrogen oxides in the flue gas are shown in Table 3, and the flue gas treatment capacity is 3200Nm 3 / h.

[0061] table 3

[0062] Composition of flue gas

NO

NO 2

HCl

temperature / ℃

Concentration (mg / Nm 3 )

625

830

432

45

[0063] In the process of ozone oxidation and denitrification treatment of flue gas, the weight ratio of ozone to nitric oxide in flue gas is controlled to be 1.6:1; in the process of washing the oxidized flue gas with water, the spray density of water is controlled to be 8m 3 / (m 2 ﹒ h), when using an alkaline solution to wash the washed flue gas, the alkaline solution uses 20% sodium hydroxide aqueous solution, and controls the nitrogen oxides and sodium hydroxide in the washed flue gas by controlling the spray speed of the alkaline sol...

Embodiment 3

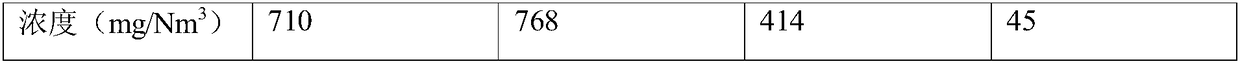

[0068] use figure 1 The de-pinning device shown denitrifies the flue gas of the wet gold and / or silver melting section. The composition and temperature of the main nitrogen oxides in the flue gas are shown in Table 5, and the flue gas treatment capacity is 8650Nm 3 / h.

[0069] table 5

[0070]

[0071]

[0072] In the process of ozone oxidation and denitrification treatment of flue gas, the weight ratio of ozone to nitric oxide in flue gas is controlled to be 2.5:1; in the process of washing the oxidized flue gas with water, the spray density of water is controlled to be 2.5 m 3 / (m 2 ﹒ h), when using an alkaline solution to wash the washed flue gas, the alkaline solution uses 20% sodium hydroxide aqueous solution, and controls the nitrogen oxides and sodium hydroxide in the washed flue gas by controlling the spray speed of the alkaline solution The molar ratio is 1:1.5.

[0073] The composition of the exhausted flue gas was tested, and the test results are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com