Material sleeve path optimization method applied to common edge cutting of pipe parts

A path optimization and cutting path technology, applied in data processing applications, forecasting, laser welding equipment, etc., can solve the problems of not supporting common edge cutting, waste of pipe raw materials, and poor processing effects, so as to improve the cutting process and reduce the loss of raw materials , Reduce the effect of laser and auxiliary gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

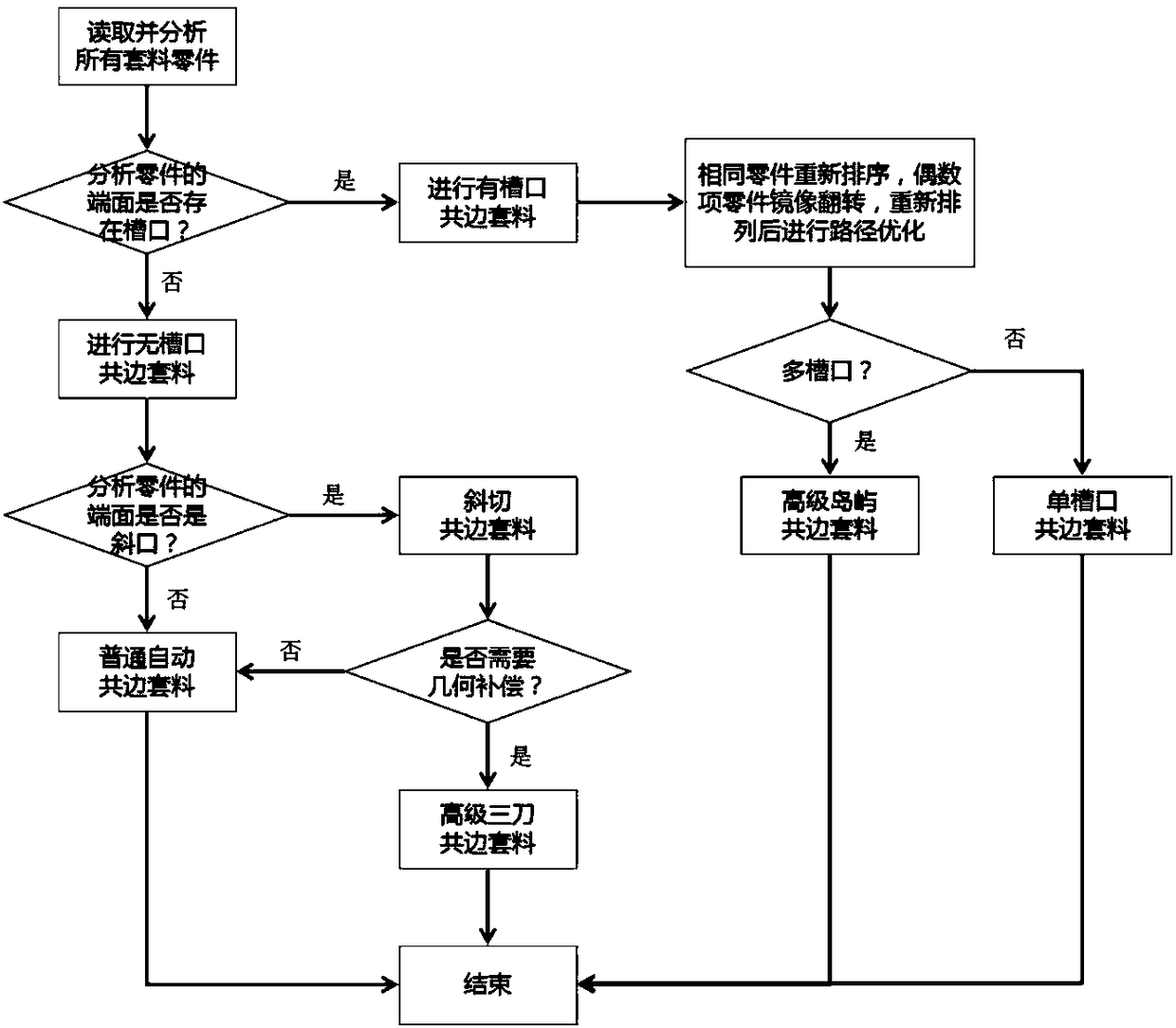

[0033] Such as figure 1 The flow chart of a nesting path optimization method applied to co-edge cutting of pipe parts is shown, and its main steps are as follows:

[0034] 1. A nesting path optimization method applied to co-edge cutting of pipe parts, characterized in that it comprises the following steps:

[0035] (1) Read and display all parts involved in nesting;

[0036] (2) Traverse the head and tail faces of all parts, check whether there is a notch on the contour on the end face, if there is no notch, go to step (3), if there are one or more notches, then directly skip to step (7);

[0037] (3) Execute non-notch co-edge nesting cutting, analyze the end face that needs to be cut, if it is a straight cut end face, then proceed to step (4), if it is a beveled end face, then proceed to step (5);

[0038] (4) Execute common automatic co-edge nesting cutting;

[0039] (5) Execute oblique cutting and co-edge nesting cutting, analyze whether geometric compensation is needed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com