Hollow extrusion integrated plastic clamping plate, and production process and equipment thereof

An all-in-one, plastic technology that can be used in packaging, metal processing, transportation and packaging to solve problems such as low production efficiency and mildew that affect the application of disposable wooden pallets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

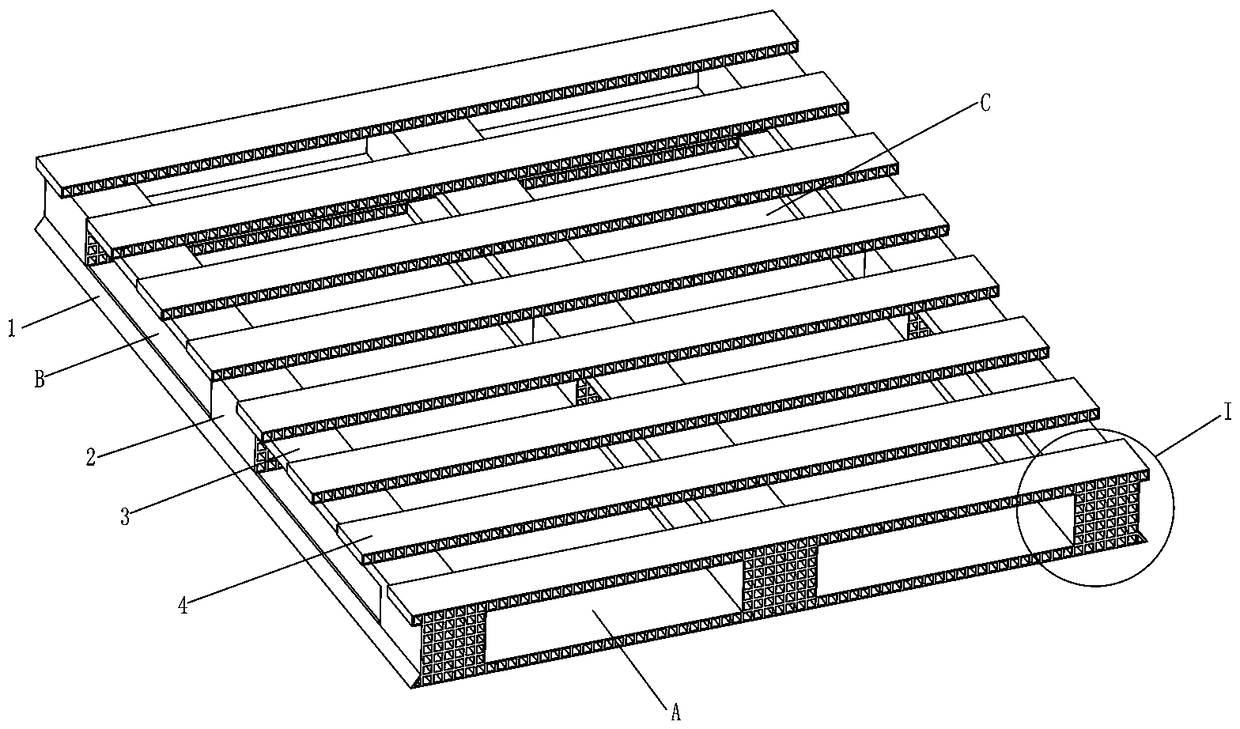

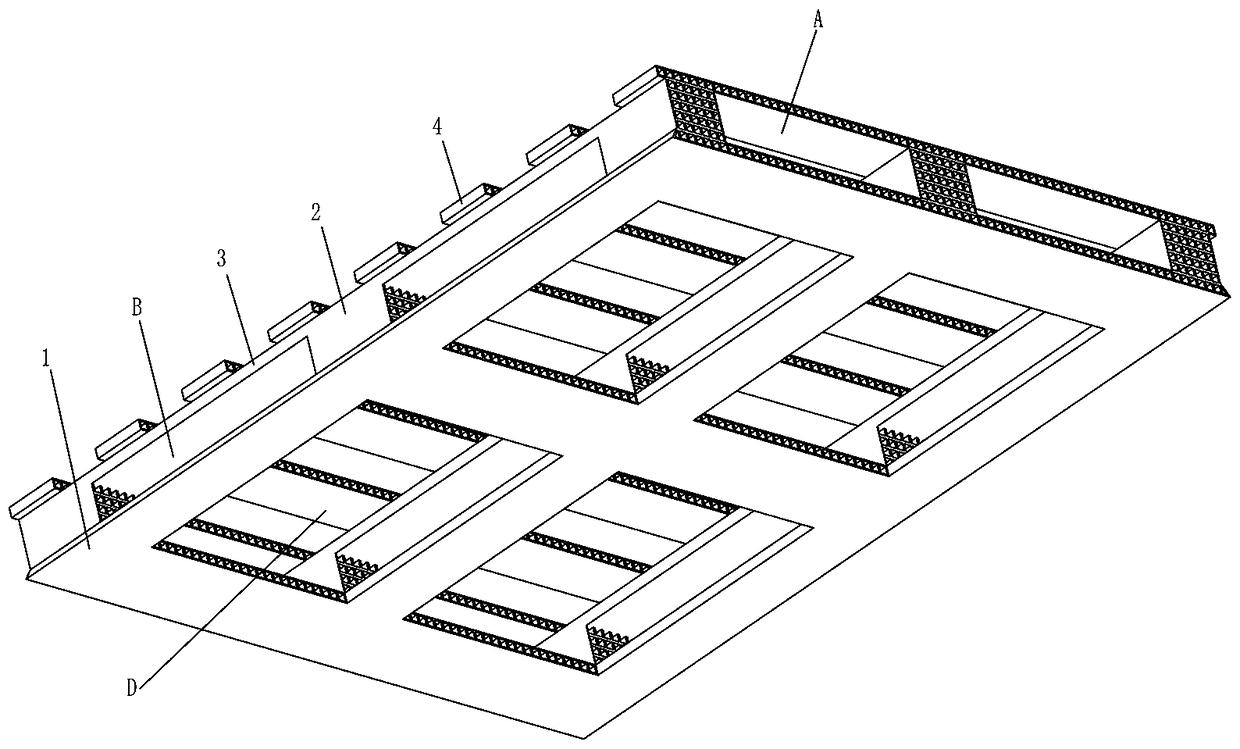

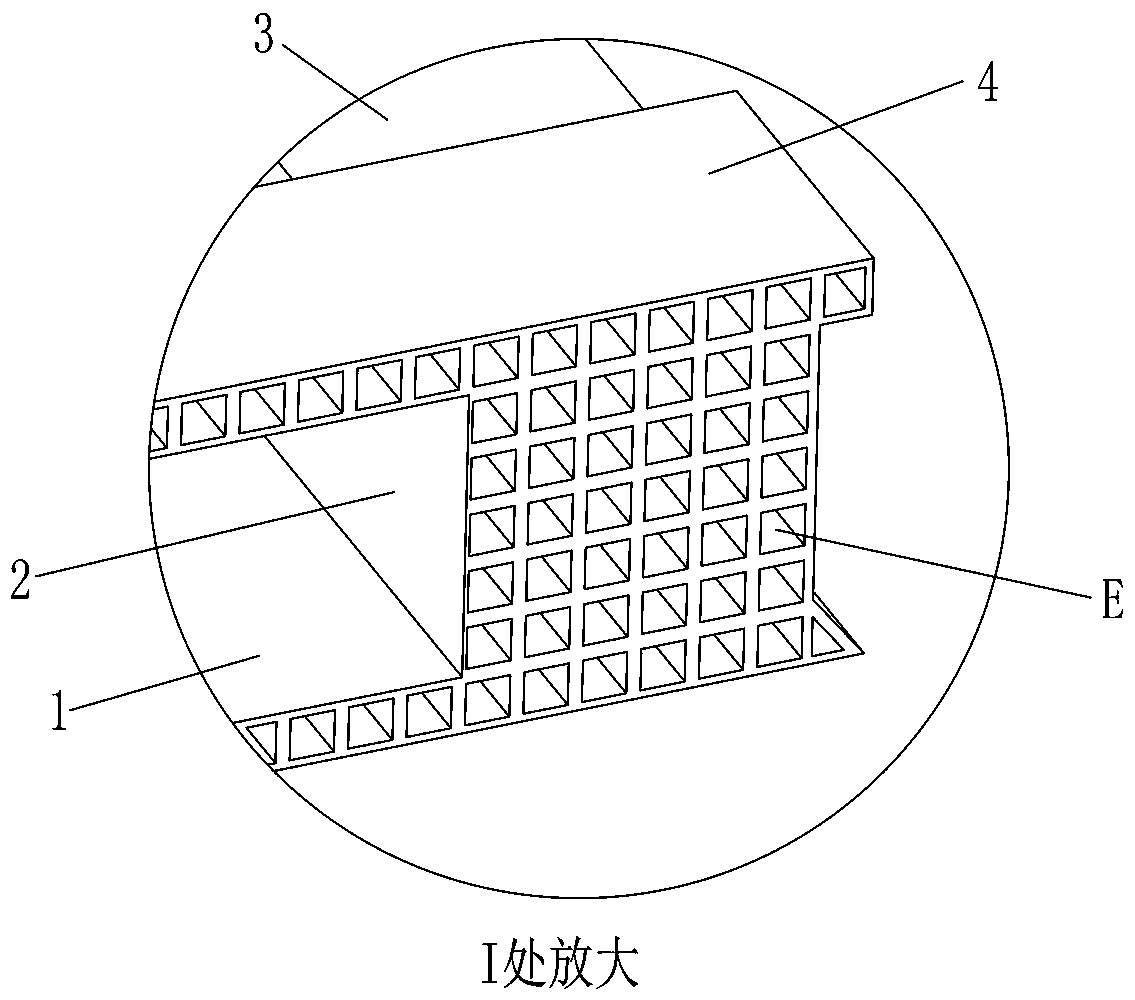

[0085] Embodiment 1: as Figure 1 to Figure 10 As shown, the technical scheme adopted by the present invention is as follows: a hollow extruded integrated plastic pallet, including a lower support plate 1, a support seat 2, a support bar 3, an upper support bar 4, a through groove A, a side groove B, a spacer Groove C and hollow groove D, wherein, the above-mentioned lower support plate 1 is a plate-shaped structure, and the hollow groove D includes at least two, and the hollow groove D is set on the lower support plate 1, and penetrates the lower support plate 1 up and down; the above-mentioned support seat 2 Including at least two supporting seats 2 arranged at intervals along the longitudinal direction on the lower support plate 1, and forming at least two mutually spaced supporting planes in the transverse direction, and a through groove A is formed between two adjacent supporting seats 2 along the longitudinal direction , forming the side slot B along the transverse direc...

Embodiment 2

[0102] Embodiment 2: as Figure 11 to Figure 20 As shown, it is Embodiment 2 of the present invention. This embodiment includes a support seat 2, a support bar 3, an upper layer support bar 4, a through groove A, a side groove B and an intermediate groove C, wherein the above-mentioned support seat 2 includes at least two , the support seats 2 are arranged at intervals along the longitudinal direction, and form at least two support planes arranged at intervals in the transverse direction, a through groove A is formed between two adjacent support seats 2 along the longitudinal direction, and a side groove B is formed along the transverse direction; the above The support bars 3 include at least two, and the support bars 3 extend along the longitudinal direction. Each support bar 3 is respectively arranged on the above-mentioned support plane and supported by the support seat 2; It is arranged on the support bars 3 at intervals, and an inter-groove C is formed between two adjacen...

Embodiment 3

[0119] Embodiment 3: as Figure 21 to Figure 28 As shown, it is embodiment 3 of the present invention, and the technical scheme adopted in this embodiment is as follows: a hollow extruded integrated plastic pallet, including a lower support plate 1, a support seat 2, an upper support plate 18, a through groove A and side Groove B, wherein, the above-mentioned lower support plate 1 is a plate-like structure; the above-mentioned support seat 2 includes at least two, and the support seats 2 are arranged at intervals on the lower support plate 1 along the longitudinal direction, and form at least two mutually spaced arrangements in the transverse direction. The supporting plane of the supporting base 2 forms a through groove A along the longitudinal direction between two adjacent support seats 2, and forms a side groove B along the transverse direction; the above-mentioned upper support plate 18 is a plate-shaped structure and is arranged on the support seat 2; the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com