Negative electrode material and preparation method thereof and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor structural stability, affecting low-temperature performance of batteries, and blocking ion channels, achieving low cost and good structural stability. , Improve the effect of low temperature charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

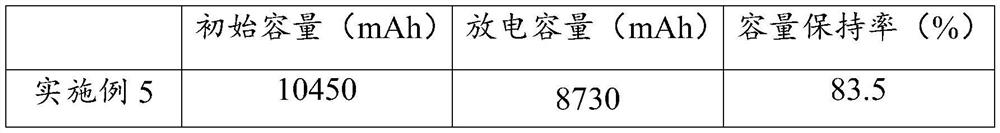

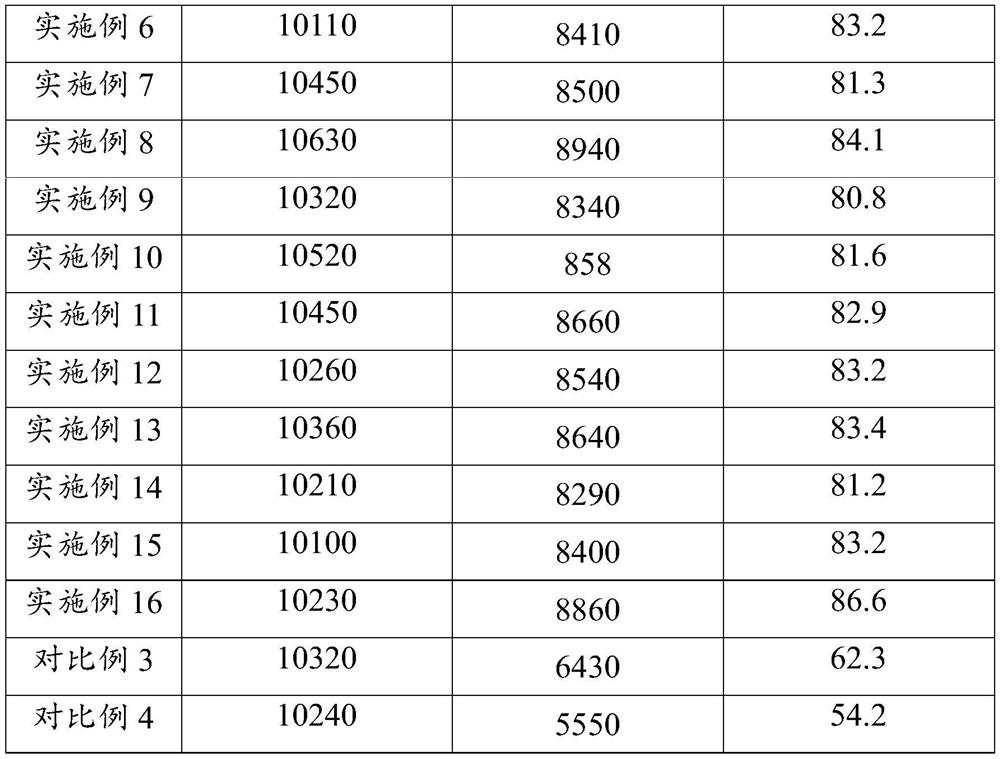

Examples

preparation example Construction

[0040] The invention provides a preparation method of the above-mentioned negative electrode material, which includes the step of mixing graphite, conductive carbon black, binder, dispersant and thickener.

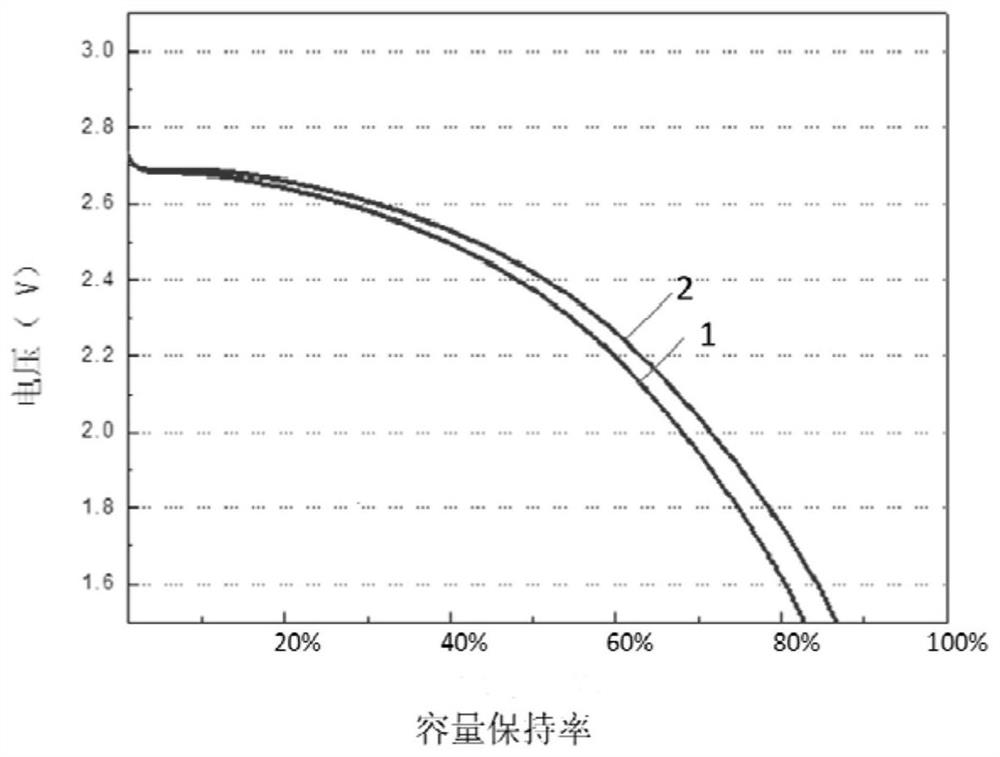

[0041] The method is simple and easy to operate, has no special requirements on equipment, has low cost, and the prepared negative electrode material has good low-temperature performance. In the preparation method, a higher revolution speed is used to process and mix raw materials, and a higher stirring speed can generate a higher shear force, so that the obtained negative electrode material has a lower porosity and a higher hardness. Furthermore, a good compact internal structure can be maintained during the charging and discharging process, and the low-temperature charging and discharging performance of the battery can be improved.

[0042] In a preferred embodiment of the present invention, graphite, conductive carbon black, dispersant, thickener, binder and deionized w...

Embodiment 1

[0057] This embodiment is a negative electrode material, including the following raw materials in weight percentage: 90% graphite, 5% conductive carbon black, 2.5% binder, 0.5% dispersant and 2% thickener.

Embodiment 2

[0059] This embodiment is a negative electrode material, including the following raw materials in weight percentage: 95% graphite, 1% conductive carbon black, 1.3% binder, 0.2% dispersant and 2.5% thickener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com