WS2/ZnIn2S4 composite visible light catalyst and preparation method thereof

A znin2s4, visible light technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of high photogenerated electron-hole recombination rate, achieve good photocatalytic hydrogen production activity, preparation method Simple, good photocatalytic performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

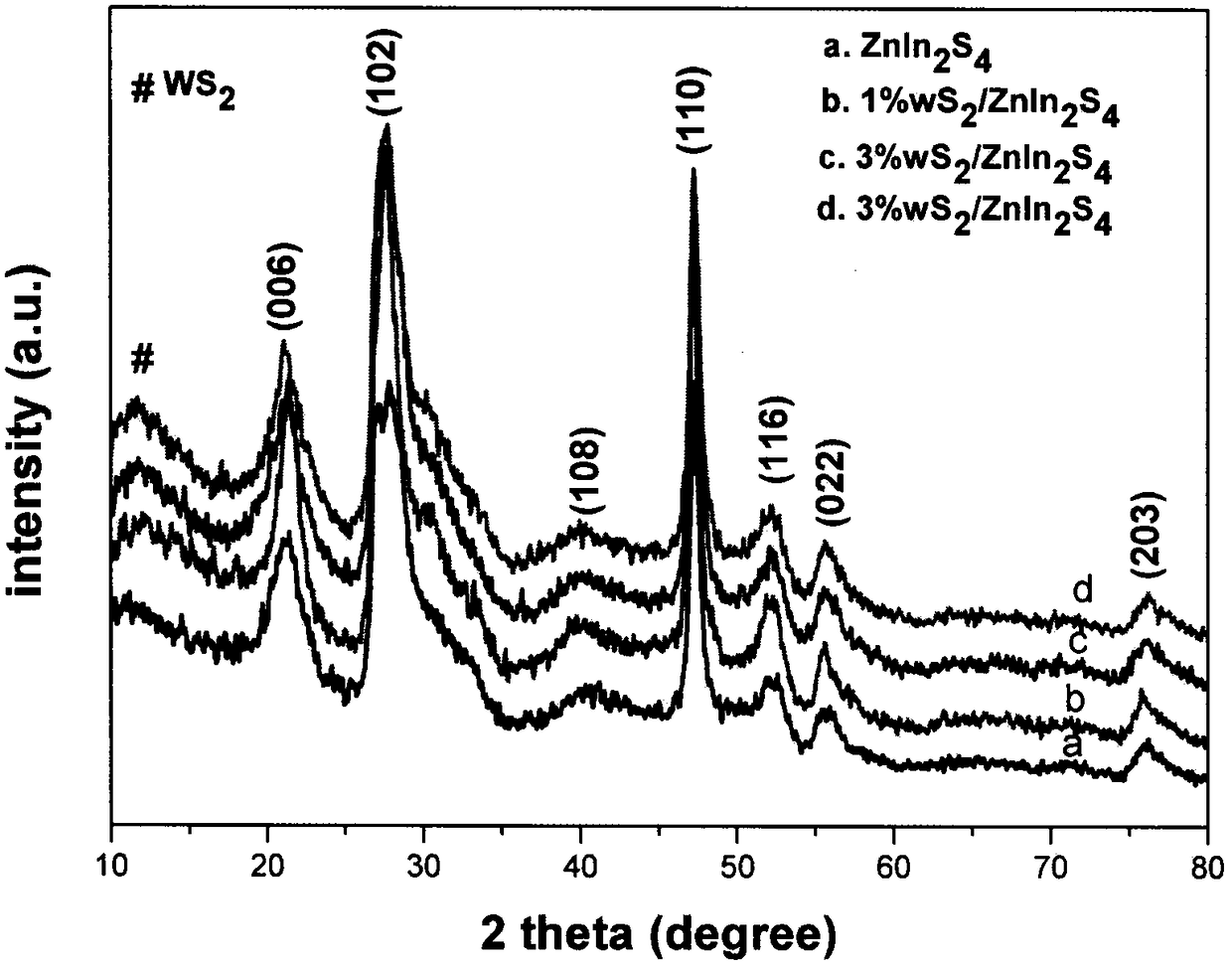

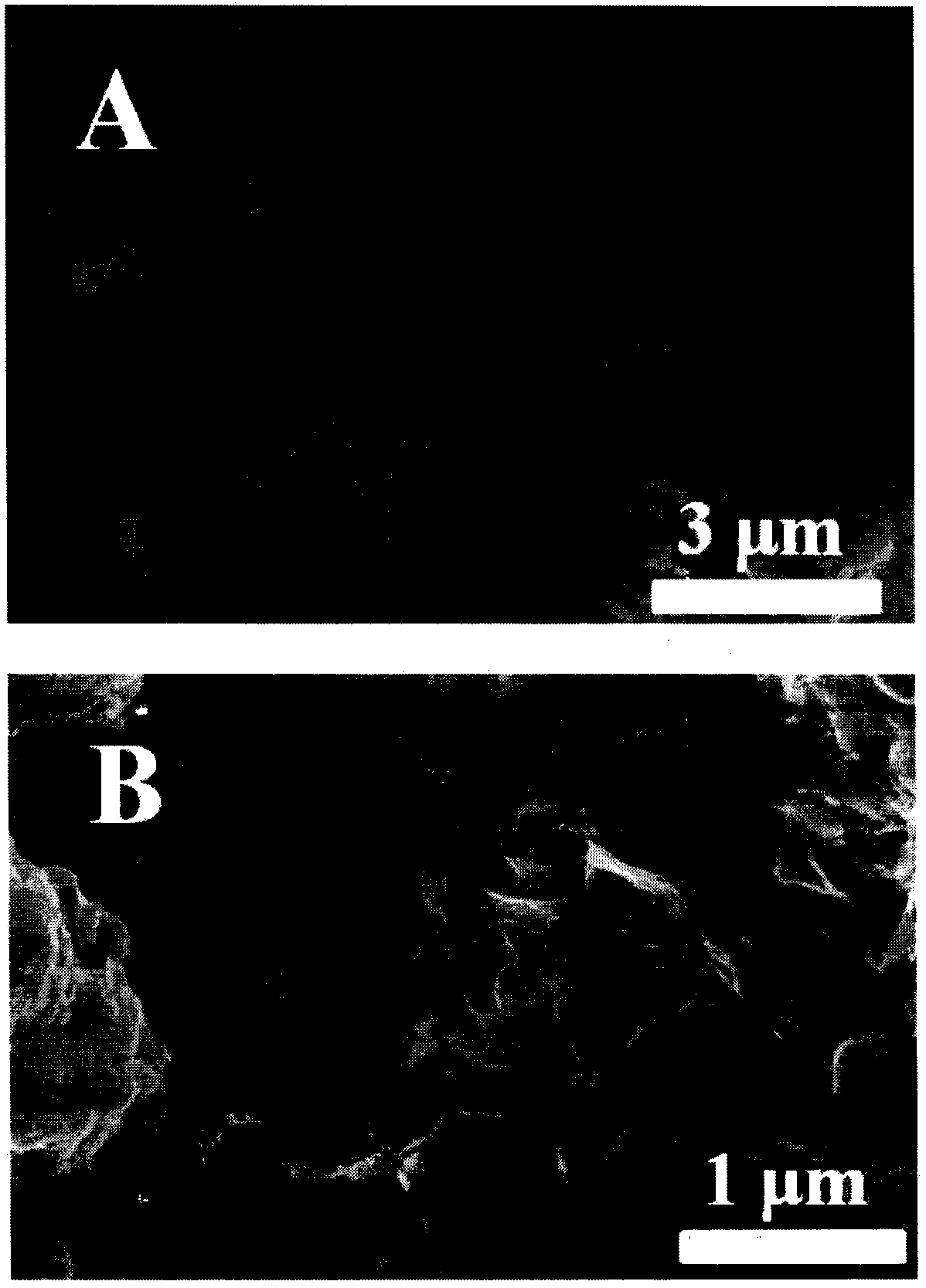

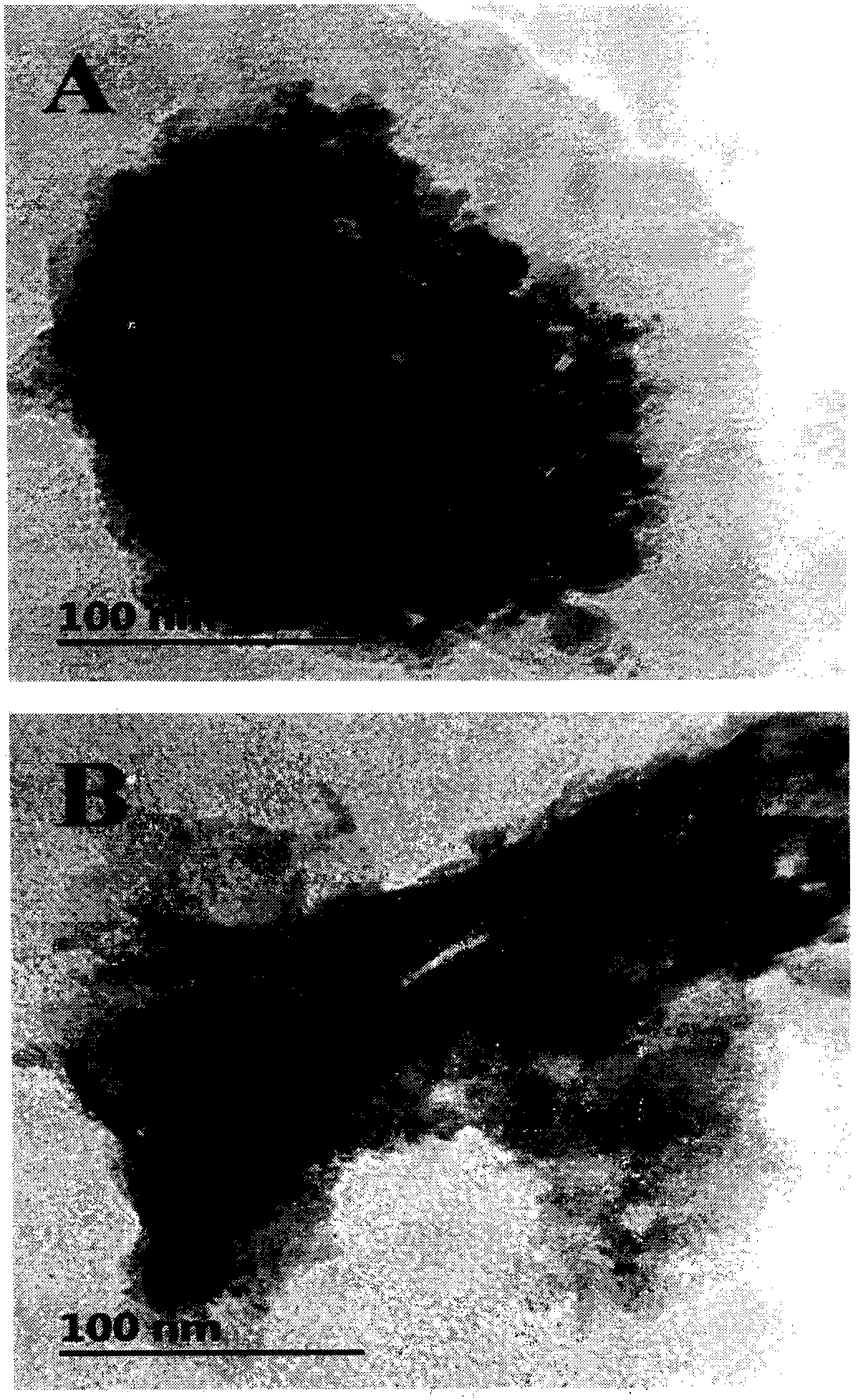

Embodiment 1

[0018] (1) Firstly, WS was prepared by hydrothermal method 2 Two-dimensional nanosheets, the specific process is: Weigh 11.897 grams of WCl 6 and 22.767 grams of thioacetamide (CH 3 CSNH 2 ) was dissolved in 400 ml of deionized water and stirred for 1 hour to form a precursor solution, and then transferred to a 500 ml hydrothermal reaction kettle for 24 hours of hydrothermal reaction at 265 degrees; after the reaction was completed, it was cooled to room temperature, and the precipitated product was collected and passed through WS can be prepared after washing with water and freeze-drying for 24 hours 2 Nanosheets;

[0019] (2) 5 mg of WS synthesized above2 The nanosheets were dispersed in 50 ml of deionized water and dispersed by strong ultrasonic for 1 hour to form WS 2 suspension; then, 2mmol of ZnCl 2 , 4mmol of In(NO 3 ) 3 ·H 2 O and 8 mmol CH 3 CSNH 2 According to the stoichiometric molar ratio of 1:2:4 sequentially dissolved into the above configuration of WS ...

Embodiment 2

[0021] (1) WS 2 The preparation process of the two-dimensional nanosheet is the same as in Example 1;

[0022] (2) 15 mg of WS synthesized above 2 The nanosheets were dispersed in 50 ml of deionized water and dispersed by strong ultrasonic for 1 hour to form WS 2 suspension; then, 2mmol of ZnCl 2 , 4mmol of In(NO 3 ) 3 ·H 2 O and 8 mmol CH 3 CSNH 2 According to the stoichiometric molar ratio of 1:2:4 sequentially dissolved into the above configuration of WS 2 In the suspension, sonicate for 30 minutes to prepare a precursor solution; after that, transfer the precursor solution to a hydrothermal reactor and react at 160 degrees for 8 hours; after the reaction, cool to room temperature and collect the reaction product by suction filtration , washed several times with absolute ethanol and deionized water, dried overnight in a vacuum oven, and finally prepared WS containing 3% by mole 2 / ZnIn 2 S 4 The composite visible light catalyst, marked as 3%WS 2 / ZnIn 2 S 4 . ...

Embodiment 3

[0024] (1) WS 2 The preparation process of the two-dimensional nanosheet is the same as in Example 1;

[0025] (2) 25 mg of WS synthesized above 2 The nanosheets were dispersed in 50 ml of deionized water and dispersed by strong ultrasonic for 1 hour to form WS 2 suspension; then, 2mmol of ZnCl 2 , 4mmol of In(NO 3 ) 3 ·H 2 O and 8 mmol CH 3 CSNH 2 According to the stoichiometric molar ratio of 1:2:4 sequentially dissolved into the above configuration of WS 2 In the suspension, sonicate for 30 minutes to prepare a precursor solution; after that, transfer the precursor solution to a hydrothermal reactor and react at 160 degrees for 8 hours; after the reaction, cool to room temperature and collect the reaction product by suction filtration , washed several times with absolute ethanol and deionized water, dried overnight in a vacuum oven, and finally prepared WS containing 5% by mole 2 / ZnIn 2 S 4 The composite visible light catalyst, marked as 5%WS 2 / ZnIn 2 S 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com