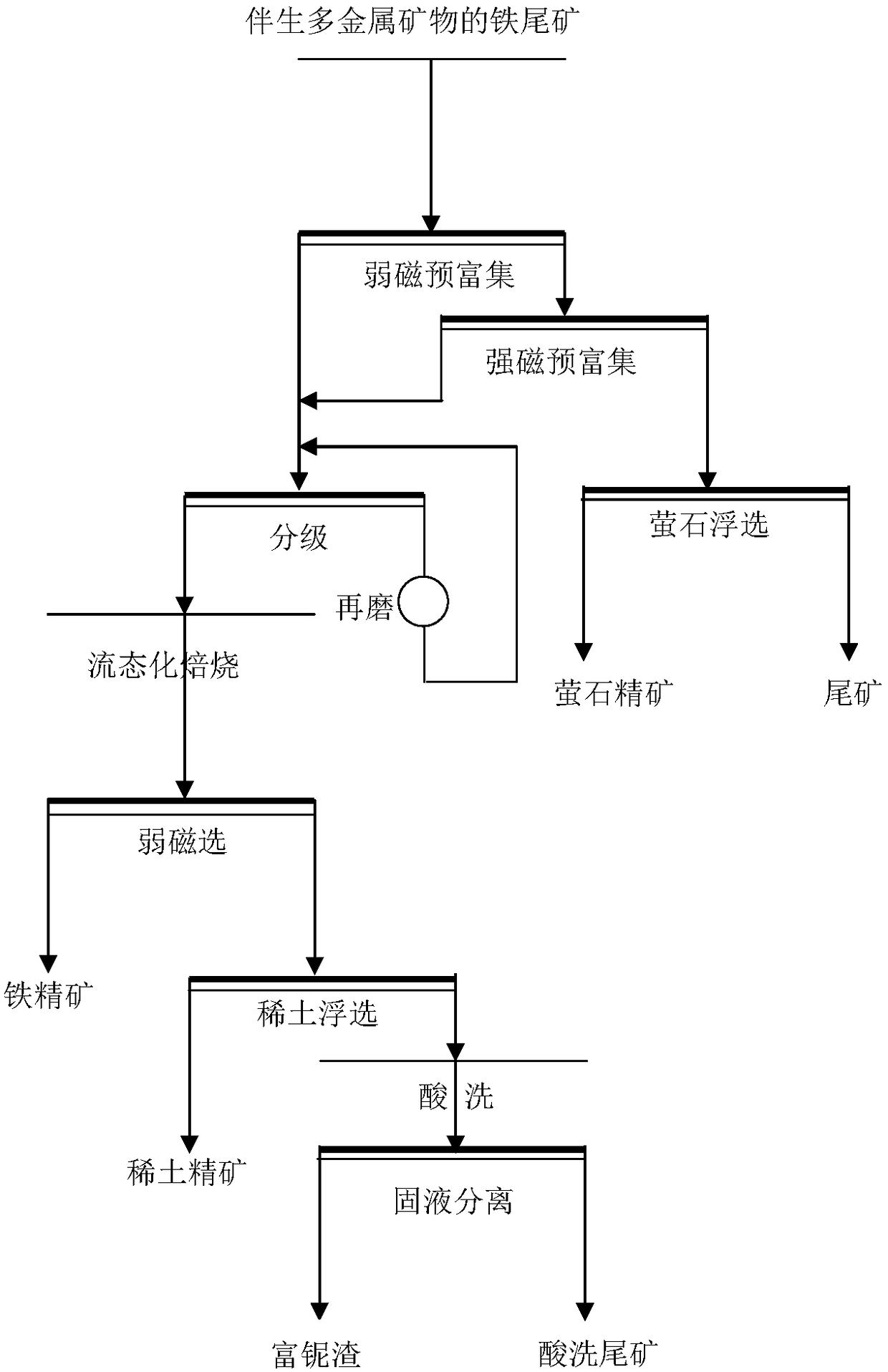

Mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals

A technology for iron tailings and polymetals, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of complex mineral types, waste of resources, refractory beneficiation, etc., to reduce the amount of fluorite flotation, The effect of reducing the dosage of reducing agent and increasing the quality of concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this example, the tailings in the Baiyun Obo tailings pond are used as raw materials, in which the grade of iron (TFe) is 18.77%, and the grade of fluorite (CaF 2 ) grade is 20.62%, rare earth (REO) grade is 7.02%. Utilize the method of the present invention to finally obtain the iron concentrate with an iron grade of 65.89% and a recovery rate of 88.75%; the rare earth concentrate with a rare earth grade of 68.54% and a recovery rate of 82.12%; the fluorite grade of 95.21% and a recovery rate of 81.53% The fluorspar concentrate specifically comprises the following steps:

[0038] (1) Feed the Baiyan Obo tailings into a wet permanent magnetic drum magnetic separator with a magnetic field strength of 0.25T to obtain weak magnetic pre-enrichment concentrates and weak magnetic pre-enrichment tailings.

[0039] (2) Feeding the weak magnetic pre-enrichment tailings into a vertical ring wet high-strength magnetic separator with a magnetic field strength of 0.65T to obtain...

Embodiment 2

[0047] In this example, the tailings in the Baiyun Obo tailings pond are used as raw materials, in which the grade of iron (TFe) is 16.10%, and the grade of fluorite (CaF 2 ) grade is 30.25%, rare earth (REO) grade is 6.00%. Utilize the method of the present invention to finally obtain the iron concentrate with an iron grade of 65.09% and a recovery rate of 85.87%; the rare earth concentrate with a rare earth grade of 66.79% and a recovery rate of 80.32%; the fluorite grade of 95.82% and a recovery rate of 82.37% The fluorspar concentrate specifically comprises the following steps:

[0048] (1) Feed the Baiyun Obo tailings into a wet permanent magnetic drum magnetic separator with a magnetic field strength of 0.2T to obtain weak magnetic pre-enrichment concentrates and weak magnetic pre-enrichment tailings.

[0049] (2) Feeding the weak magnetic pre-enrichment tailings into a vertical ring wet high-strength magnetic separator with a magnetic field strength of 0.6T to obtain h...

Embodiment 3

[0057] In this example, the tailings in the Baiyun Obo tailings pond are used as raw materials, in which the grade of iron (TFe) is 17.74%, and the grade of fluorite (CaF 2 ) grade is 28.96%, rare earth (REO) grade is 6.85%. Utilize the method of the present invention to finally obtain the iron concentrate with an iron grade of 66.13% and a recovery rate of 77.69%; the rare earth concentrate with a rare earth grade of 65.21% and a recovery rate of 81.57%; the fluorite grade of 95.63% and a recovery rate of 81.86% The fluorspar concentrate specifically comprises the following steps:

[0058] (1) Feed the Baiyun Obo tailings into a wet permanent magnetic drum magnetic separator with a magnetic field strength of 0.2T to obtain weak magnetic pre-enrichment concentrates and weak magnetic pre-enrichment tailings.

[0059] (2) Feeding the weak magnetic pre-enrichment tailings into a vertical ring wet high-strength magnetic separator with a magnetic field strength of 0.65T to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com