A system and method for anti-icing using sliding discharge plasma

A technology of discharge plasma and plasma, which is applied to deicing devices, transportation and packaging, aircraft parts, etc. The effect of bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

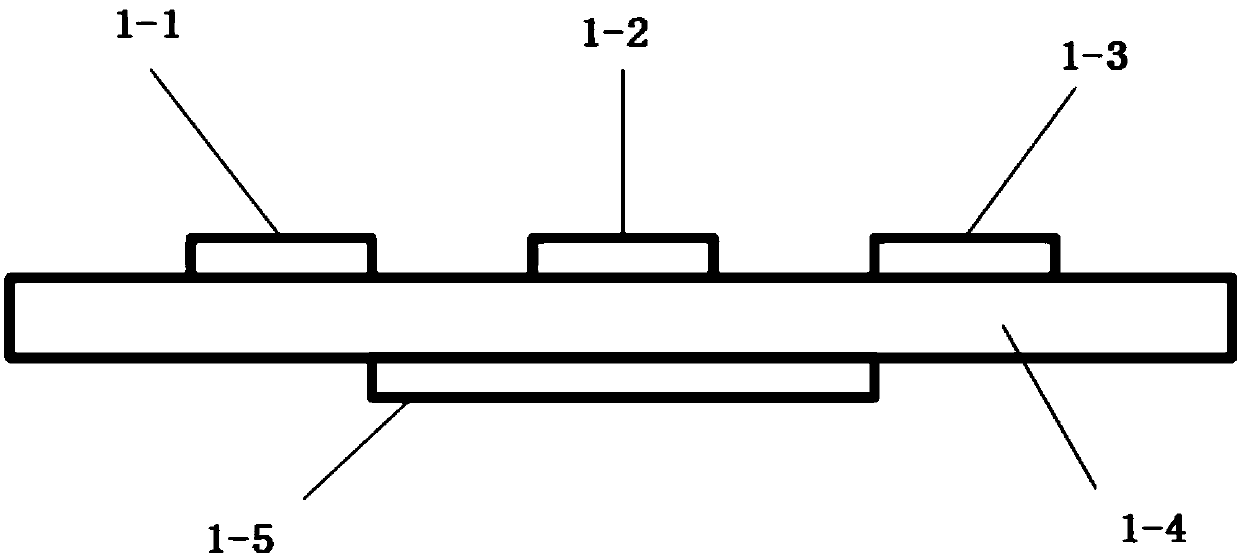

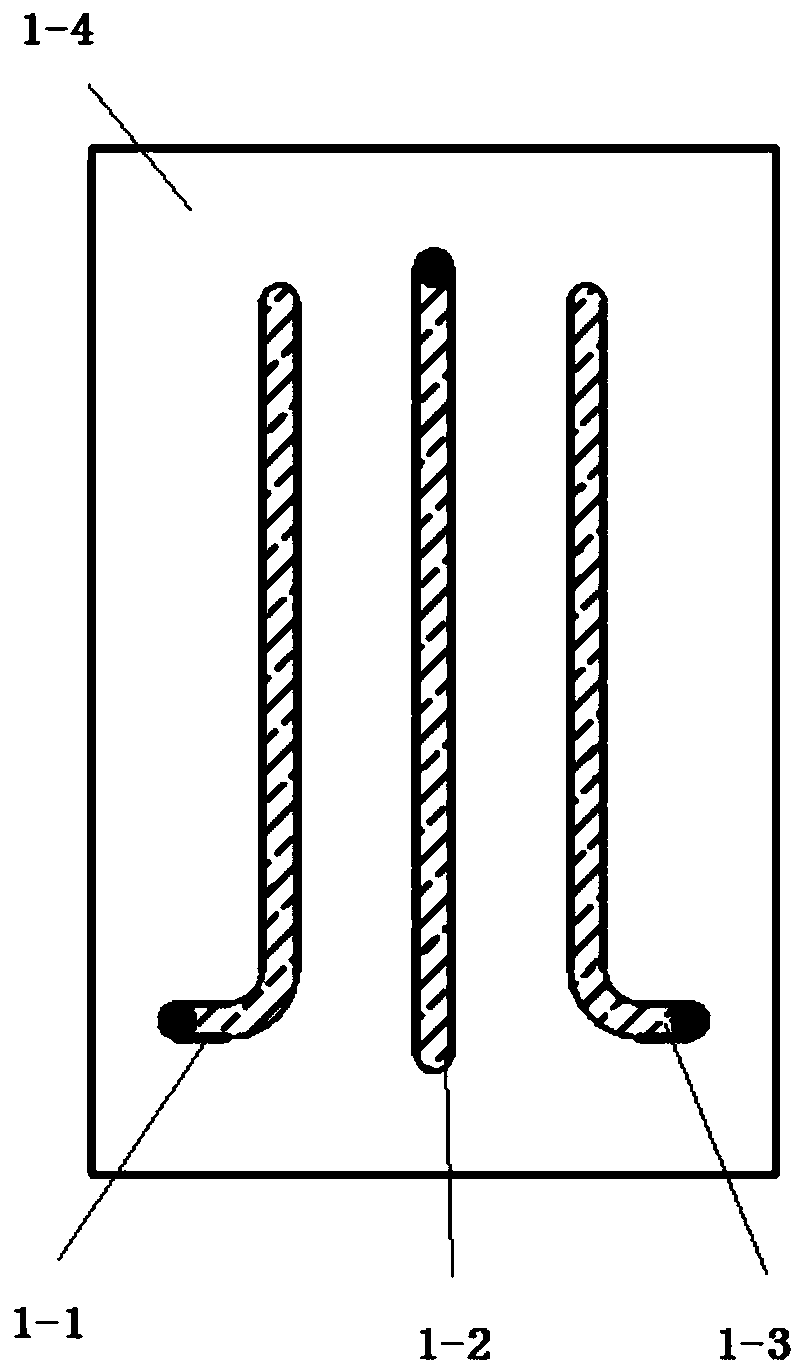

[0048] like Figure 5 As shown, the experimental model 5 is a NACA0015 airfoil with a chord length of 300mm and a span length of 500mm. The electrodes of the sliding discharge plasma exciter 1 are made of copper, and the copper electrodes are inlaid on the surface of a soft thin-film silicon rubber sheet. The upper and lower electrodes are treated the same way, and the thin-film silicon rubber sheet is covered on The surface of the airfoil forms a sliding discharge plasma excitation structure.

[0049] The upper electrode consists of three electrodes, the first upper electrode 1-1 is 200mm long and 5mm wide; the second upper electrode 1-2 is 200mm long and 5mm wide; the third upper electrode 1-3 is the The mirror image centered on the second upper electrode 1-2.

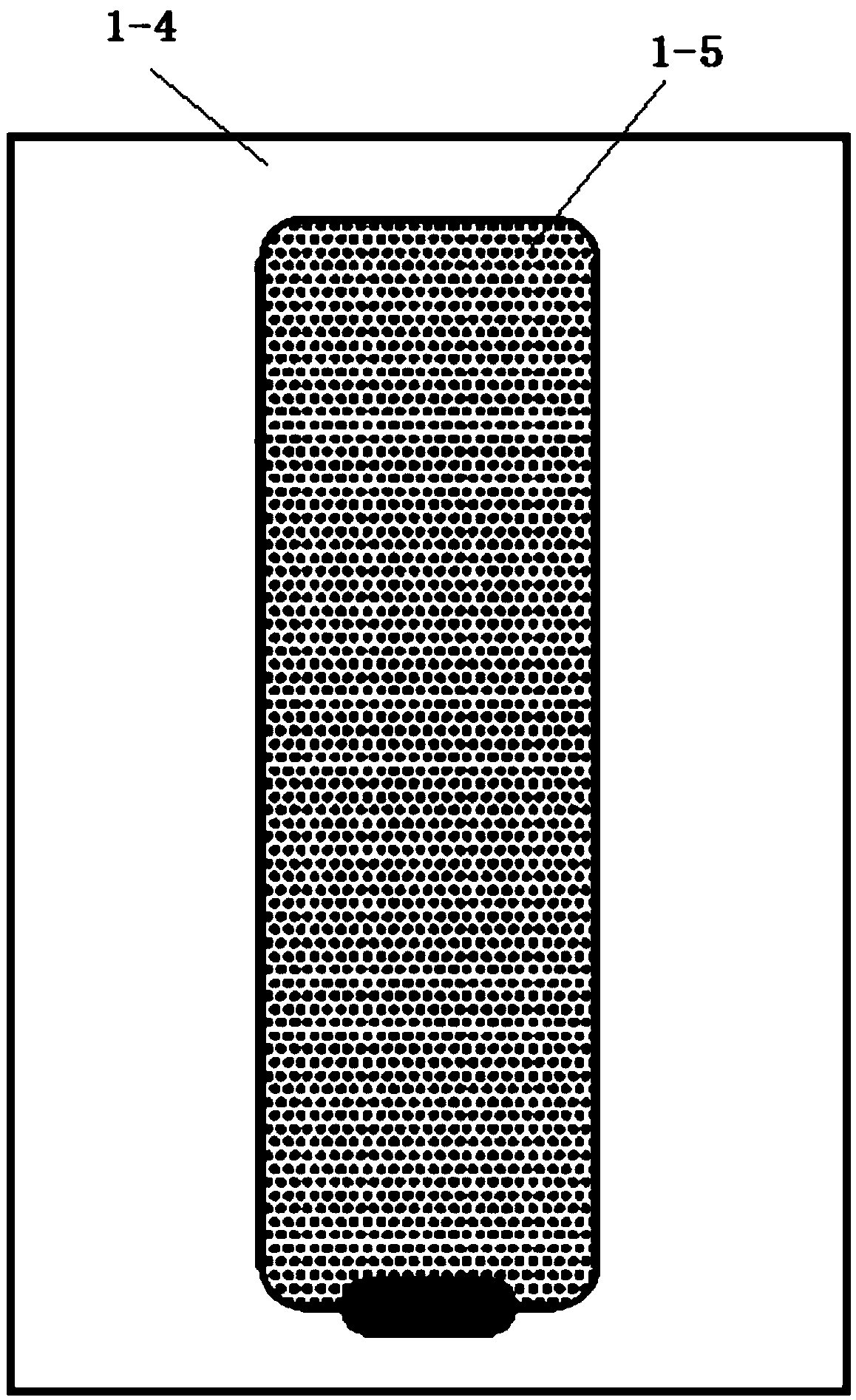

[0050] The insulating dielectric layers 1-4 are made of thin-film silicone rubber sheets with a thickness of 1mm.

[0051] The lower electrode layers 1-5 are composed of monolithic copper electrodes with a length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com