High-strength wear-resistant nonel tube and preparation method thereof

A detonating tube, high-strength technology, applied in blasting tubes, offensive equipment, weapon accessories, etc., can solve the problems of low impact blasting resistance of the tube wall, high cost of materials and equipment, immature manufacturing technology, etc., and achieve excellent anti-diameter Tensile properties, good shock resistance, and high powder viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

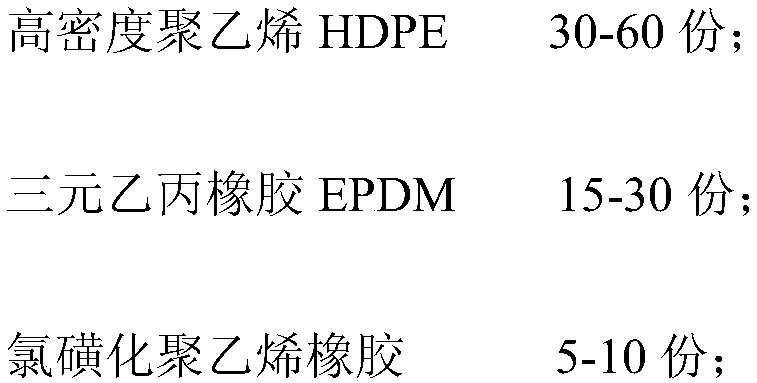

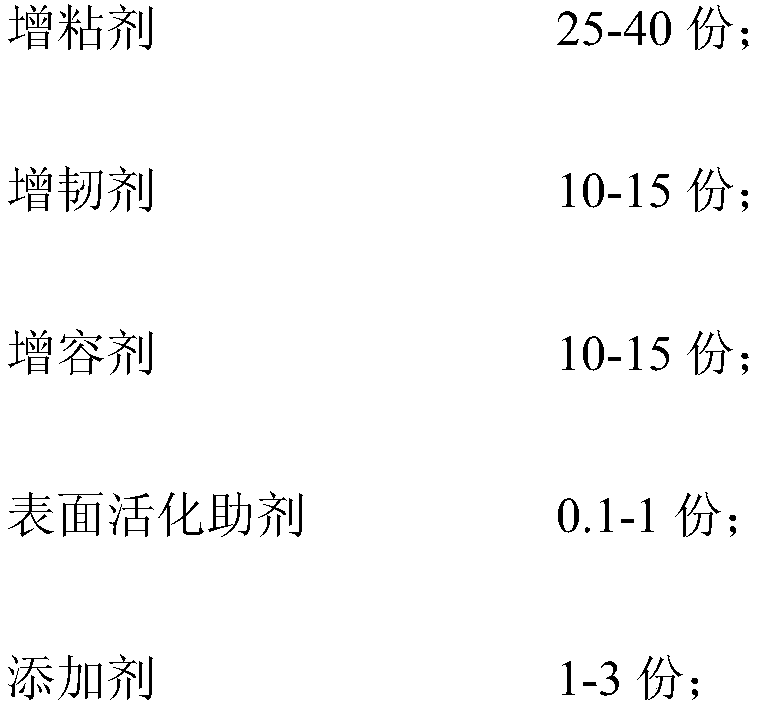

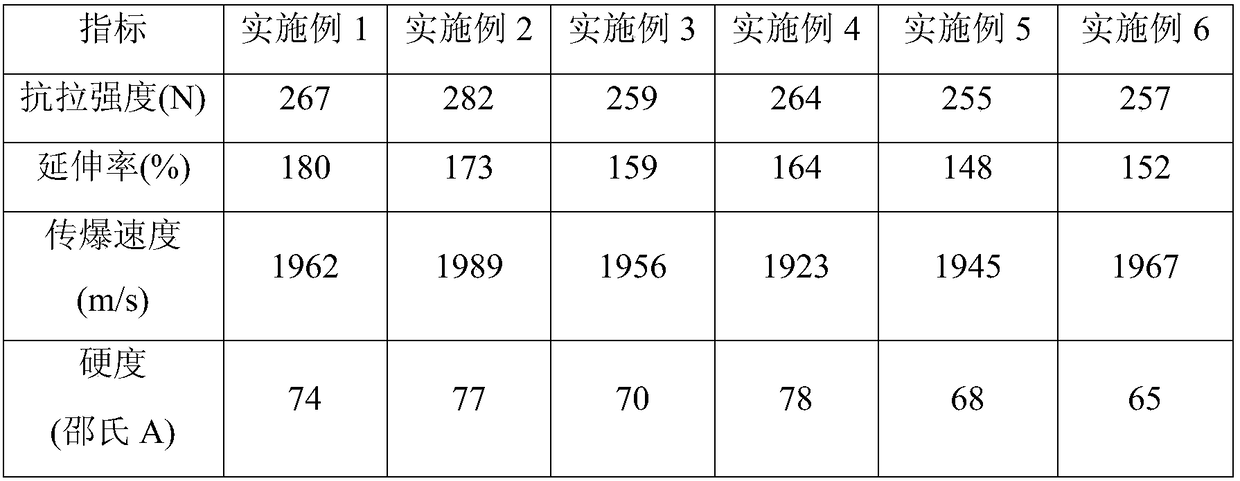

[0040] The high-strength wear-resistant nonel of the present embodiment includes the following components in parts by weight:

[0041] HDPE: 50 parts; EPDM: 20 parts, its vinyl content is 52% (weight), Mooney viscosity (ML(1+4), 125 ℃) 43MU; chlorosulfonated polyethylene rubber: 5 parts, its chlorine content is 32 % (weight), Mooney viscosity (ML(1+4), 100 ℃) at 44MU; tackifying resin: 30 parts, a blend material of EAA and EMA, the mixing weight ratio is 1:0.3, AA content in EAA It is 8.5% (weight), and the melt index is 9.7g / 10min, and the MA content is 7.8% (weight) in the EMA, and the melt index is 8.5g / 10min; Toughener: 10 parts, POE and m-LLDPE mixing weight ratio are 1:3; compatibilizer: 10 parts, AA grafting rate is 3.2% (weight); surface-activated rare earth nano additives: 0.1 part, is CeO2, the average particle size is 20nm; antioxidant: 1 part, antioxidant The weight ratio of agent 1010 to DLTP is 1:2; lubricant: 1 part, which is stearic acid.

[0042] According t...

Embodiment 2

[0052] The high-strength wear-resistant nonel of the present embodiment includes the following components in parts by weight:

[0053] HDPE: 40 parts; EPDM: 25 parts, its vinyl content is 52% (weight), Mooney viscosity (ML(1+4), 125 ℃) 43MU; chlorosulfonated polyethylene rubber: 5 parts, its chlorine content is 32 % (weight), Mooney viscosity (ML(1+4), 100 ℃) at 44MU; tackifying resin: 35 parts, a blend material of EAA and EMA, the mixing weight ratio is 1:0.3, AA content in EAA It is 8.5% (weight), and the melt index is 9.7g / 10min, and the MA content is 7.8% (weight) in the EMA, and the melt index is 8.5g / 10min; Toughener: 10 parts, POE and m-LLDPE mixing weight ratio are 1:3; compatibilizer: 10 parts, AA grafting rate is 3.2% (weight); surface-activated rare earth nano additives: 0.1 part, is CeO2, the average particle size is 20nm; antioxidant: 1 part, antioxidant The weight ratio of agent 1010 to DLTP is 1:2; lubricant: 1 part, which is stearic acid.

[0054] According t...

Embodiment 3

[0064] The high-strength wear-resistant nonel of the present embodiment includes the following components in parts by weight:

[0065] HDPE: 50 parts; EPDM: 20 parts, its vinyl content is 58% (weight), Mooney viscosity (ML(1+4), 125 ℃) 52MU; chlorosulfonated polyethylene rubber: 5 parts, its chlorine content is 32 % (weight), Mooney viscosity (ML(1+4), 100 ℃) at 44MU; tackifying resin: 30 parts, a blend material of EAA and EMA, the mixing weight ratio is 1:0.5, AA content in EAA It is 8.5% (weight), and the melt index is 9.7g / 10min, and the MA content is 7.8% (weight) in the EMA, and the melt index is 8.5g / 10min; Toughener: 10 parts, POE and m-LLDPE mixing weight ratio are 1:3; compatibilizer: 10 parts, AA grafting rate is 3.2% (weight); surface-activated rare earth nano additives: 0.1 part, is CeO2, the average particle size is 20nm; antioxidant: 1 part, antioxidant The weight ratio of agent 1010 to DLTP is 1:2; lubricant: 1 part, which is stearic acid.

[0066] According t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com