Waterproof thermal insulation coating and preparation method thereof

A technology of thermal insulation coating and thermal insulation powder, which is applied in the direction of anti-corrosion coatings, reflection/signal coatings, coatings, etc. It can solve the problems of affecting waterproof, anti-corrosion and thermal insulation performance, poor stability and durability of coatings, and insufficient compactness of paint films, etc., to achieve excellent Waterproof and thermal insulation effect, high stability, good waterproof and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

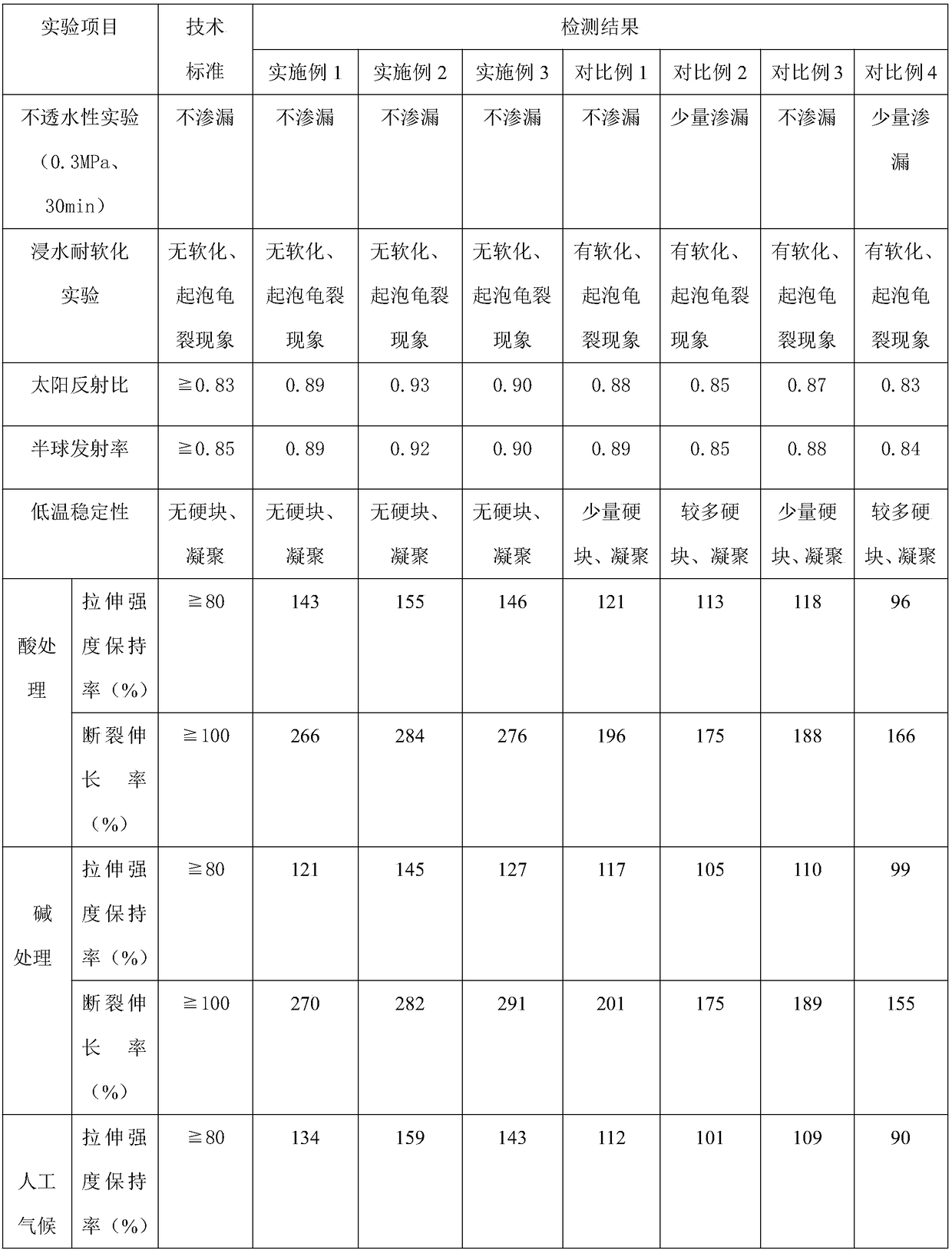

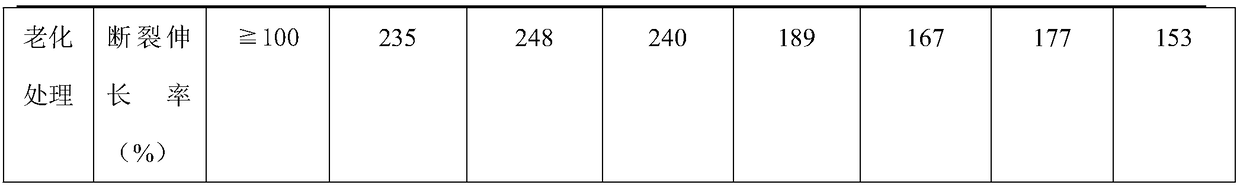

Examples

Embodiment 1

[0046] 1) Weigh 5% deionized water according to the mass percentage, add 1.5% ethylene glycol, 0.1% wetting agent, 0.3% dispersant, 0.1% defoamer, Preservative 0.1%, leveling agent 0.1%, color paste 0.1%, disperse evenly under 1200r / min high-speed stirring to obtain a mixture;

[0047] 2) Stir at a medium speed of 500r / min, add 0.4% film-forming aids, 10% rutile titanium dioxide, 5% calcined kaolin, 3% mica powder, and 1% nano heat insulation to the mixture powder, 0.5% airgel, 0.3% hydroxyethyl cellulose, 0.2% thixotropic magnesium aluminum silicate, 0.77% aluminum sulfide, 1% 4-phenylbutylmethyldichlorosilane, at 1200r After being uniformly dispersed under high-speed stirring at 1 / min, put it into a sand mill for sand grinding, and the fineness of the sand-milled mixture is 45 μm;

[0048] 3) Put the sand-milled mixture into a disperser, add 8% hollow glass microspheres under a medium-speed stirring of 500r / min, and after the dispersion is uniform, add 30% of styrene-acryli...

Embodiment 2

[0050] 1) Weigh 10% deionized water according to mass percentage, add 0.2% ethylene glycol, 0.15% wetting agent, 0.8% dispersant, 0.15% defoamer, 0.3% preservative, 0.2% leveling agent, 0.2% color paste, uniformly dispersed under 800r / min high-speed stirring, to obtain a mixture;

[0051] 2) Under medium speed stirring at 600r / min, add 0.5% film-forming aids, 12% rutile titanium dioxide, 10% calcined kaolin, 5% mica powder, and 0.5% nano heat insulation to the mixture powder, 2% airgel, 0.1% hydroxyethyl cellulose, 0.1% thixotropic magnesium aluminum silicate, 0.5% aluminum sulfide, 1.55% 4-phenylbutylmethyldichlorosilane, at 800r After being uniformly dispersed under high-speed stirring at 1 / min, put it into a sand mill for sand grinding, and the fineness of the sand-milled mixture is 50 μm;

[0052] 3) Put the sand-milled mixture into a disperser, add 5% hollow glass microspheres under a medium-speed stirring of 600r / min, and after the dispersion is uniform, add 20% of styr...

Embodiment 3

[0054] 1) Weigh 7.82% deionized water according to mass percentage, add 0.8% ethylene glycol, 0.12% wetting agent, 0.5% dispersant, and 0.13% defoamer successively under stirring at a low speed of 150r / min, Preservative 0.2%, leveling agent 0.15%, colorant 0.2%, disperse evenly under 1000r / min high-speed stirring to obtain a mixture;

[0055] 2) Stir at a medium speed of 600r / min, add 0.5% film-forming aids, 10% rutile titanium dioxide, 6% calcined kaolin, 4% mica powder, and 0.5% nano heat insulation to the mixture powder, 1% airgel, 0.1% hydroxyethyl cellulose, 0.3% thixotropic magnesium aluminum silicate, 1% aluminum sulfide, 2% 4-phenylbutylmethyldichlorosilane, at 1000r After being uniformly dispersed under high-speed stirring per min, put it into a sand mill for sand grinding, and the fineness of the sand-milled mixture is 55 μm;

[0056] 3) Put the sand-milled mixture into a disperser, add 4% hollow glass microspheres under a medium-speed stirring of 600r / min, and afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com