Method for preparing tetrabutylammonium hydroxide by taking tetrabutylammonium sulfate as raw material

A technology of tetrabutylammonium hydroxide and tetrabutylammonium sulfate, applied in electrolysis process, electrolysis components, electrolysis organic production and other directions, can solve the problems of low purity of tetrabutylammonium hydroxide, difficult to meet the requirements of microelectronics industry, etc. Process safety and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

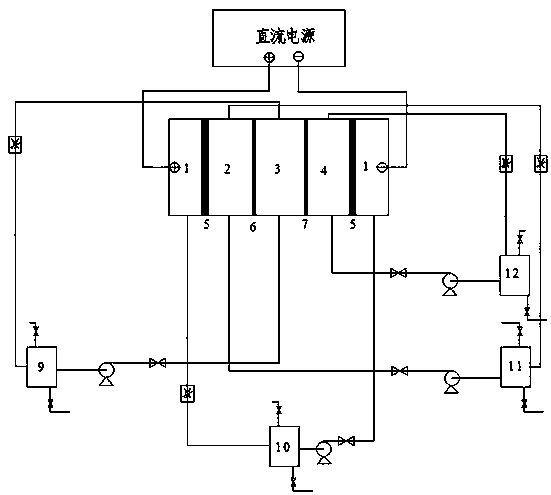

Image

Examples

Embodiment 1

[0016] Will contain 30g / L of (TBA) 2 SO 4 The solution is subjected to three-compartment bipolar membrane electrodialysis. The equipment adopts Japanese bipolar membrane, Japanese cation exchange membrane and German anion exchange membrane. The polar liquid is 0.3mol / L sulfuric acid solution, and the current density of the electrolysis process is 200A / m 2 , the flow rate of the feed liquid chamber is 0.25L / h, electrodialysis is 3.5h, the conductivity of the solution in the feed liquid chamber is 1.3ms at the end, and the conductivity of the solution in the lye chamber is 3.7ms, generating 0.098mol of tetrabutylammonium hydroxide, tetrabutylammonium hydroxide The recovery rate of ammonium was 76.5%.

Embodiment 2

[0018] Will contain 70g / L of (TBA) 2 SO 4 The solution is subjected to three-compartment bipolar membrane electrodialysis. The equipment adopts German bipolar membrane, Japanese cation exchange membrane and Japanese anion exchange membrane. The polar liquid is 0.3mol / L sulfuric acid solution. The current density of the electrolysis process is 400A / m 2 , the flow rate of the feed liquid chamber is 0.3L / h, electrodialysis is 2.8h, the conductivity of the solution in the feed liquid chamber is 3.6ms at the end, and the conductivity of the solution in the lye chamber is 8.2ms, generating 0.26mol of tetrabutylammonium hydroxide, tetrabutylammonium hydroxide The recovery rate of ammonium was 84.2%.

Embodiment 3

[0020] Will contain 200g / L of (TBA) 2 SO 4 The solution is subjected to three-compartment bipolar membrane electrodialysis. The equipment adopts Japanese bipolar membrane, Japanese cation exchange membrane and Japanese anion exchange membrane. The polar liquid is 0.3mol / L sulfuric acid solution, and the current density of the electrolysis process is 600A / m 2 , the feed liquid chamber flow rate is 0.35L / h, electroosmosis. The recovery rate of ammonium was 82.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com