Sea wind wave dynamic load test device and method

A technology of dynamic loading and test equipment, applied in the direction of program control, instrument, electrical program control, etc., can solve the problems that the frequency and amplitude of cyclic load cannot be adjusted, and the operation of test equipment is not easy, etc., and achieve simple structure, easy operation and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

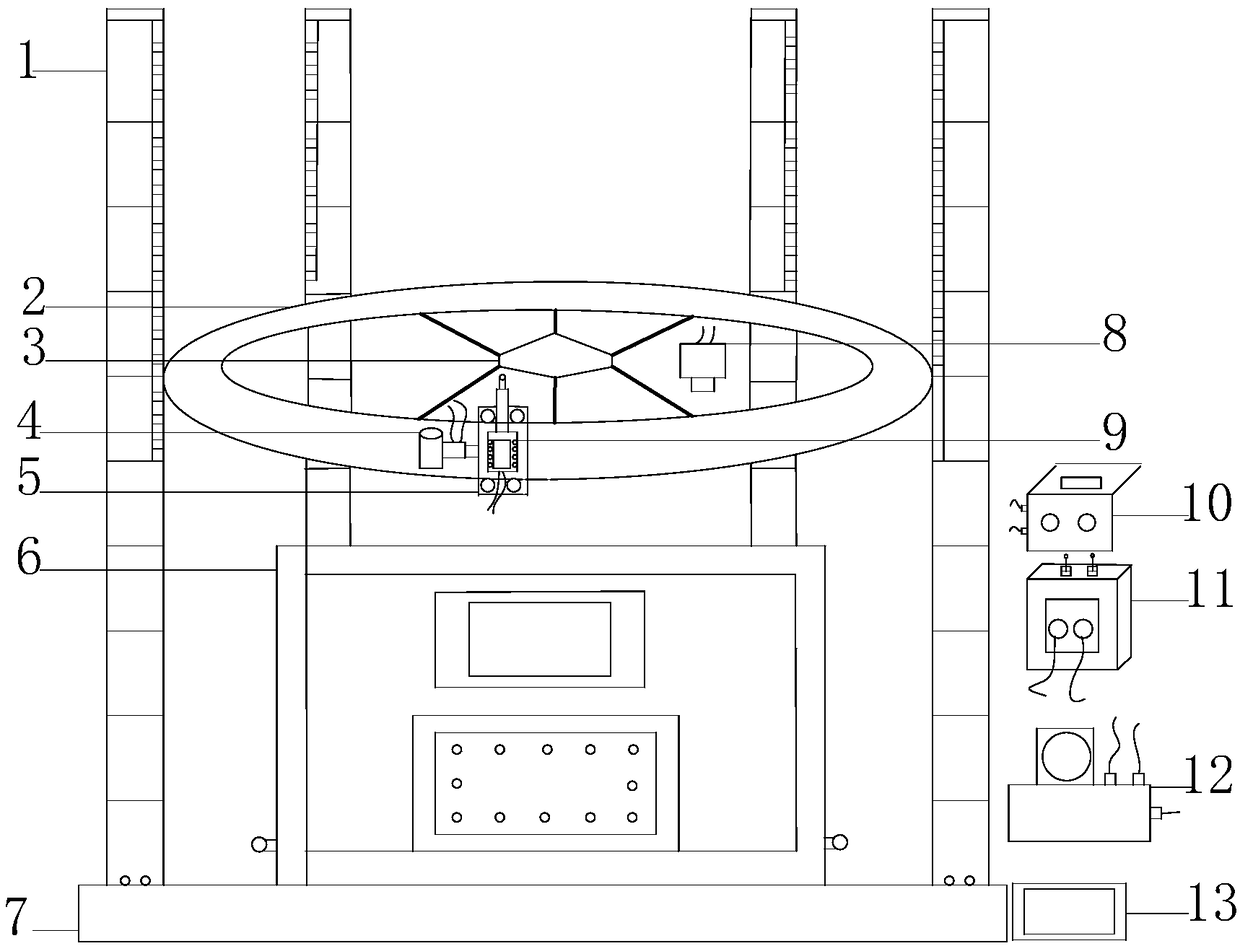

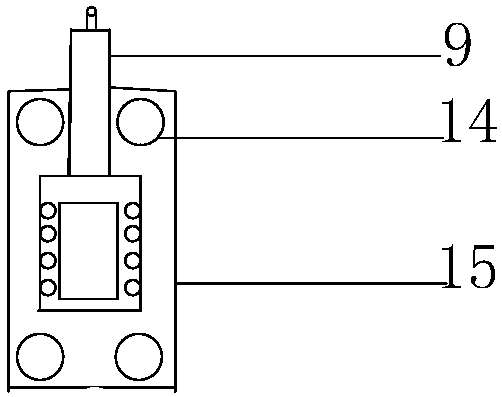

[0015] The main structure of the sea wind and wave dynamic loading test device described in this embodiment includes a reaction force column 1, a horizontal circular track 2, a six-degree-of-freedom information collector 3, a frequency conversion motor 4, a sliding block 5, a model box 6, a base 7, information Processor 8, servo motor 9, information transmitter 10, PLC operation controller 11, oil pump 12 and servo loading controller 13, wherein the horizontal circular track 2, sliding block 5, and frequency conversion motor 4 form a horizontal circular displacement control system, Servo motor 9, oil pump 12 and servo loading controller 13 form a servo loading system, six degrees of freedom information collector 3, information processor 8, information transmitter 10, and data lines form a displacement feedback information system, and PLC operation controller 11 controls In the system, the model box 6 is installed in the middle of the base 7, four reaction force columns 1 are ve...

Embodiment 2

[0022] In this embodiment, the specific process of using the offshore wind and wave dynamic loading test device to simulate the pipe pile test under the sea wind and wave is as follows:

[0023] (1) First, the variable frequency motor 4 is connected to the control system through the data line, and the control system is opened to check whether the variable frequency motor 4 can run normally on the horizontal circular track 2;

[0024] (2) Then the six degrees of freedom information collector 3, the information processor 8, and the information transmitter 10 in the displacement feedback information system are connected by data lines, start the displacement feedback information system, and check whether each part works normally;

[0025] (3) The oil pump 12 is connected with the servo motor 9 through the oil pipe, then the servo loading controller 13 is connected with the oil pump 12 through the data line, and the servo loading controller 13 is opened to check whether the servo lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com