Mixing ratio design method of macroporous high-polymer mixture

A high molecular polymer and mix ratio design technology, applied in the direction of material analysis, design optimization/simulation, suspension and porous material analysis, etc., can solve the problems of no involvement, high pollution, loose and peeling mixture, etc., and achieve easy operation , the effect of simple design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In order to achieve the above object, the technical scheme adopted in the present invention is:

[0050] The main composition of polymer adhesive is urethane prepolymer containing isocyanate group (-NCO). The synthetic raw materials are oligomer polyol and diisocyanate. The content of each component depends on the viscosity of the adhesive. After exposure to air, it can be combined with Moisture in the air reacts to solidify and release gas. The basic properties of the polymer adhesive selected in this example are shown in Table 1.1.

[0051] Table 1.1 Performance indicators of polymer adhesives

[0052]

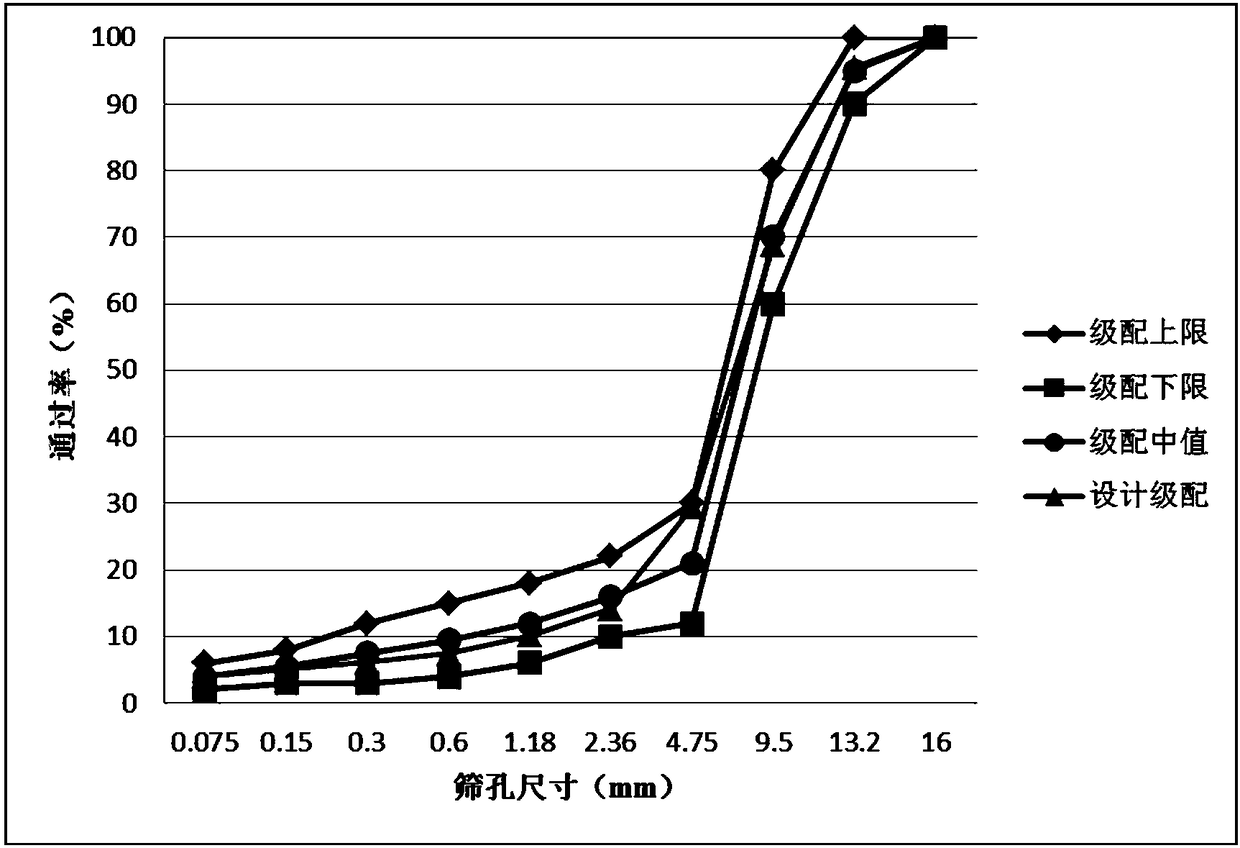

[0053] Refer to the OGFC-13 asphalt mixture gradation design interval stipulated in "Technical Specifications for Highway Asphalt Pavement Construction" (JTG F40—2004), design the aggregate gradation of macroporous polymer mixture, and the gradation design table is shown in Table 1.2 , the gradation design is shown in figure 1 as shown, figure 1 is the gradatio...

Embodiment 2

[0109] In order to achieve the above object, the technical scheme adopted in the present invention is:

[0110] The polymer adhesive is the same as in Example 1, and its basic properties are shown in Table 1.1.

[0111] Refer to the OGFC-13 asphalt mixture gradation design interval stipulated in "Technical Specifications for Highway Asphalt Pavement Construction" (JTG F40—2004), design the aggregate gradation of macroporous polymer mixture, and the gradation design table is shown in Table 2.1 , the gradation design is shown in Figure 5 As shown, the upper limit and the lower limit of the gradation are the OGFC-13 asphalt mixture gradation design range stipulated in the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004), and the median value of the gradation is the upper limit and the upper limit of the gradation. The middle value of the lower limit of the grading, and the design grading is the actual application value within the interval b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com