Method and device for checking repeated resistance in printed circuit board

A technology of printed circuit boards and circuit boards, which is applied to the layout inspection of printed circuit boards and the field of repetitive resistance inspection in printed circuit boards. It can solve problems such as low efficiency and easy missed inspections, so as to improve work efficiency and reduce processing cost, and the effect of reducing design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows.

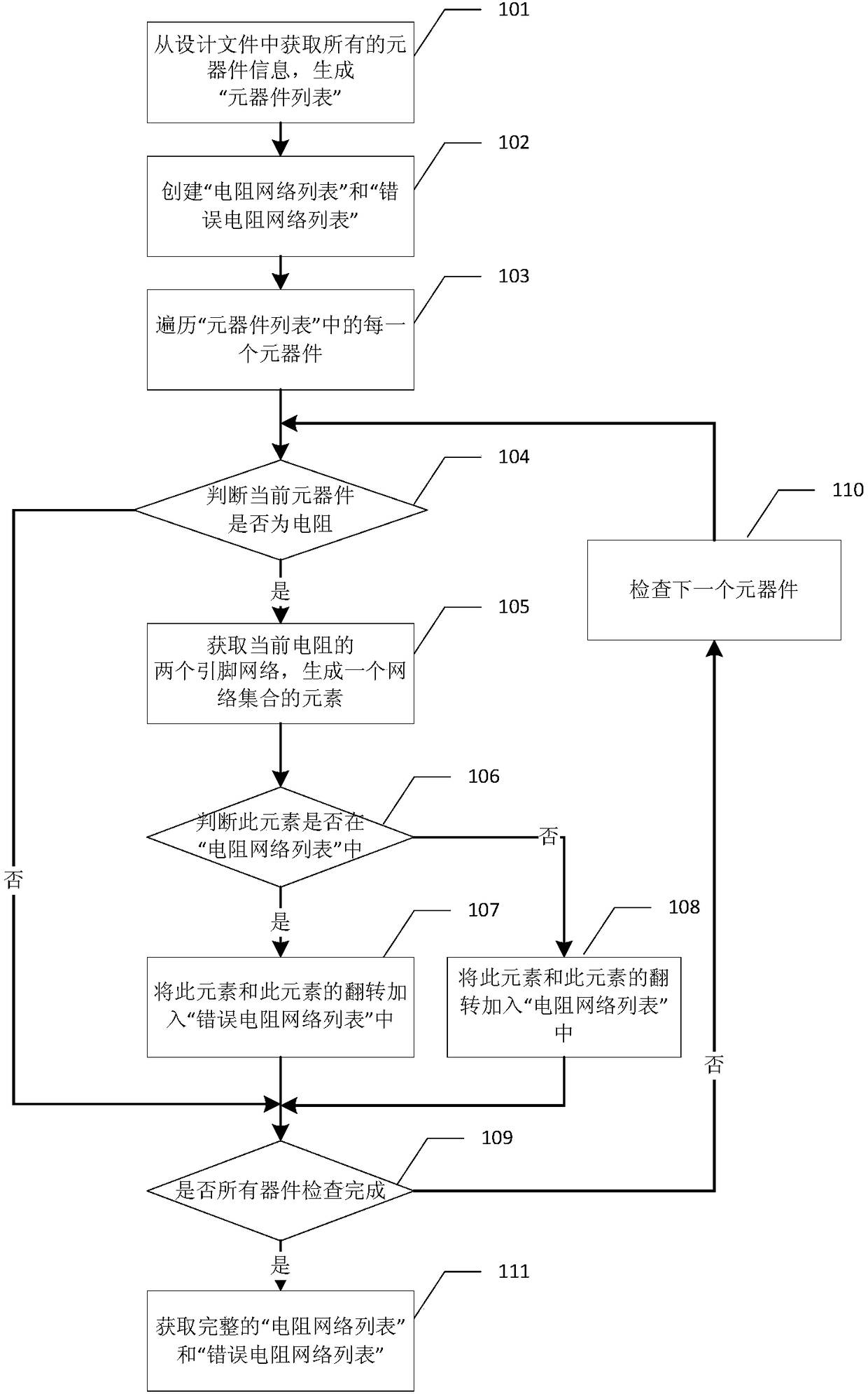

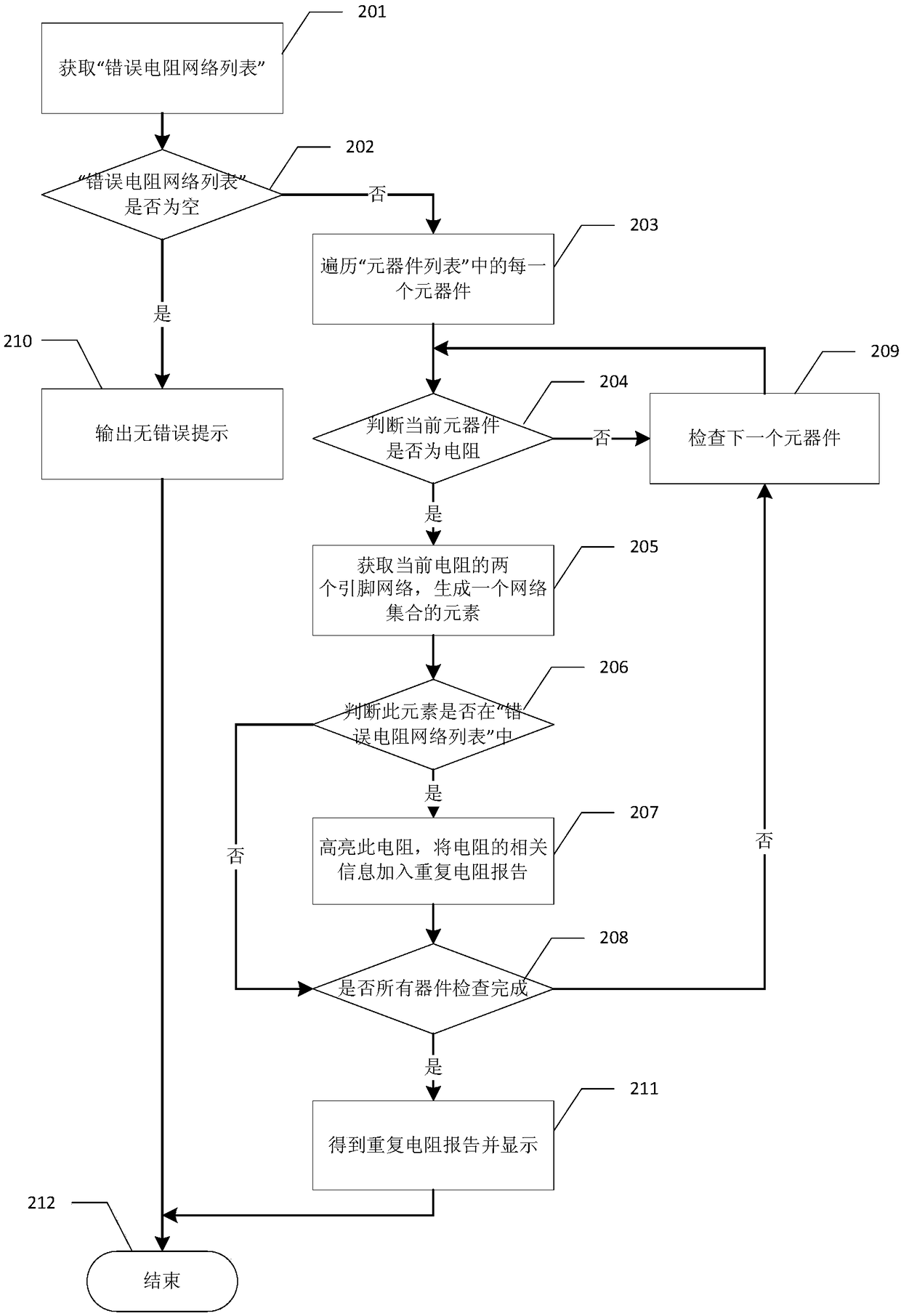

[0055] The invention writes a program file for checking the repeated resistance in the printed circuit board and saves it as a callable file format of the circuit board design software, and the circuit board design software calls the program file to perform the repeated resistance check.

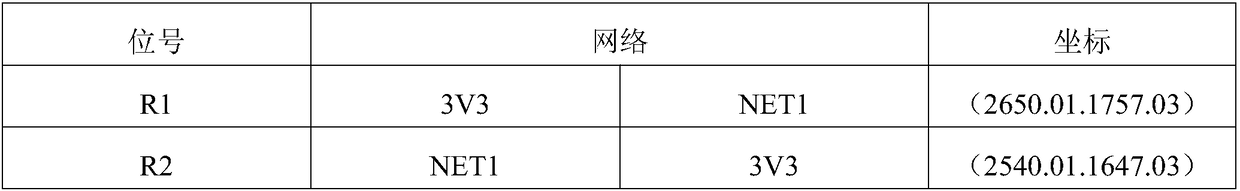

[0056] Common printed circuit board (Printed Circuit Board, PCB) design software includes Protel, Mentorpads, Cadence Allegro, etc. Taking Cadence Allegro software as an example, the inspection of PCB design can be realized through the secondary development of its SKILL platform. For example, in the embodiment of the present invention, the SKILL program for checking the repeated resistance in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com