BIM technology-based aluminum alloy template construction method

A technology of aluminum alloy formwork and construction method, which is applied in 3D modeling, image data processing, special data processing applications, etc., to achieve the effects of reducing environmental pollution, high turnover rate, rich three-dimensional sense and intuition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

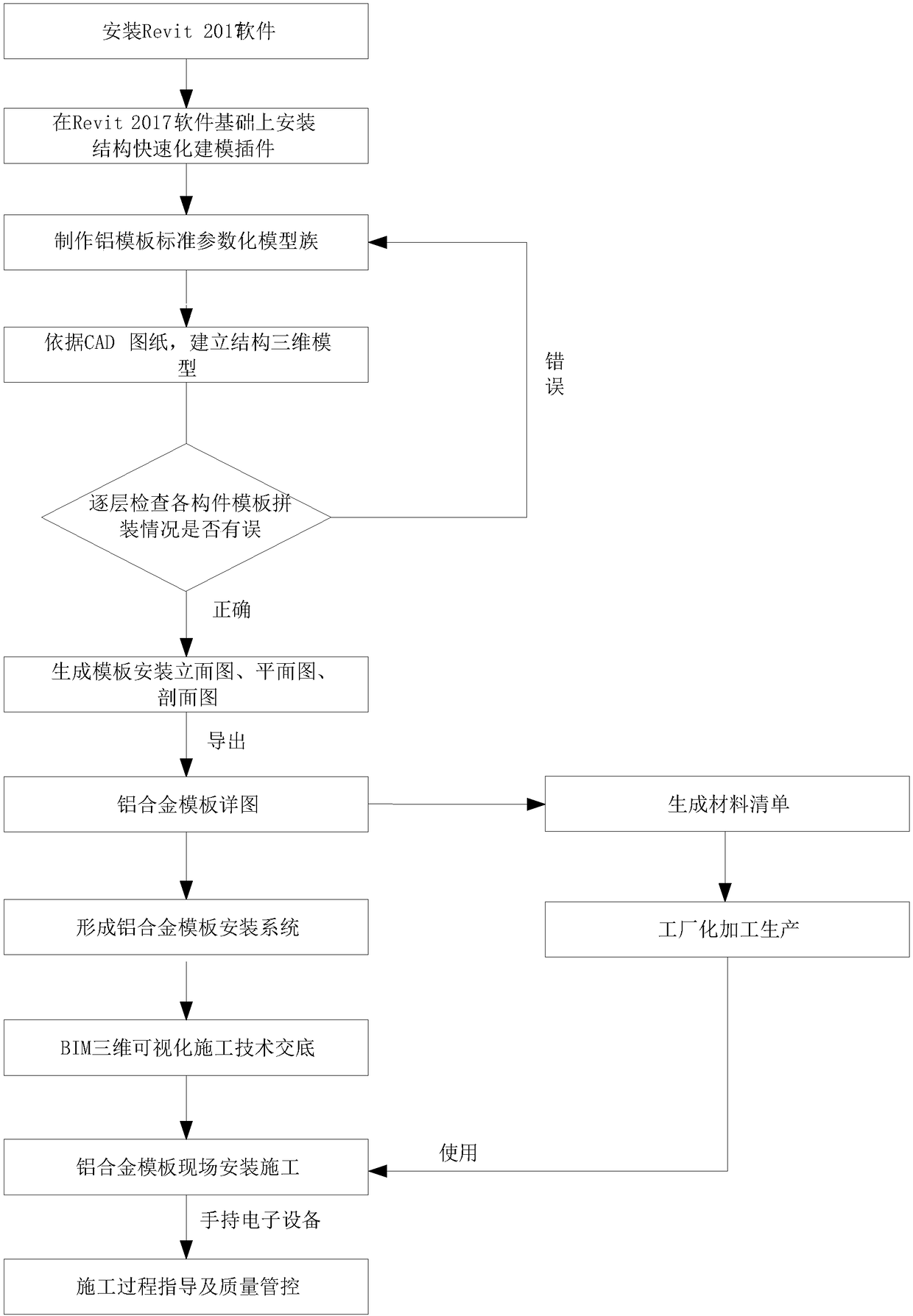

[0020] see figure 1 , providing a construction method of aluminum alloy formwork based on BIM technology, including the following steps:

[0021] Step 1: Install Revit 2017 software, and install the structural rapid modeling plug-in on the basis of Revit 2017 software;

[0022] Step 2: According to the characteristics of the project structure, use Revit 2017 software to make a standard parametric model family of aluminum alloy formwork, including wall panels, beam panels, and floor panels, to facilitate the splicing and quantitative statistics of the BIM 3D model of aluminum alloy formwork;

[0023] Step 3: According to the CAD drawings, directly read the structural design data through the rapid structural modeling plug-in, and establish a three-dimensional model of the structure. The three-dimensional model of the structure includes the shape and size of beams, slabs, columns, and wall components, as well as the structure composed of each component overall shape;

[0024] S...

Embodiment example

[0029] Based on the description in Embodiment 1 above, another template family implementation example is provided as follows, including the following steps:

[0030] Step 1: Wall formwork family: the width is mainly 450mm and 500mm, supplemented by 50mm, 100mm, 150mm, and 200mm, and the length is the net height of the floor minus the height of the floor corner formwork (horizontal corner formwork);

[0031] Step 2: Wall corner formwork family: width 100x100mm, length is the net height of the floor minus the floor corner formwork (horizontal corner formwork) height;

[0032] Step 3: Column formwork family: the width is mainly 200mm, supplemented by 50mm and 100mm, and the length is the net height of the floor minus the height of the floor corner formwork (horizontal corner formwork);

[0033] Step 4: beam formwork family: the standard length of the bottom formwork is 900mm, the standard width is 200mm, the standard length of the side formwork is 1200mm, the standard width is 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com